TECH Meets BUSINESS

Penguin Instruments Inc. pioneered a device that rendered used syringes harmless by melting, and they are engaged in projects to commercialize research seeds as devices and produce order-made devices that generate smells. They undertake the planning, design, and development of various products that can better serve society, by identifying society’s needs for hardware, and promoting projects that act as a bridge to research seeds.

Representative Director and President of Penguin Instruments Inc. In 1997 he joined Penguin Systems Co., Ltd., in 2003 he was appointed Director, and in 2006 he was appointed Representative Director and President. He established and was appointed Representative Director and President of Idea Co., Ltd. in 2010. In 2015 he was appointed Chairman (Representative of the Board of Directors) of Ibaraki R&D Association (IRDA). In 2019 he changed the business name of Idea Co., Ltd. to Penguin Instruments Inc. He holds various positions such as member of the Ibaraki Prefecture General Planning Council, member of the NHK Broadcast Program Council, etc.

Birth of a company in response to the needs for hardware

― What led you to establish Penguin Instruments Inc.?

As background to its founding there is Penguin Systems Co., Ltd, a sister company founded in 1983 and is now in its 37th year. This is a software contract development company whose customers are mainly researchers in research institutes and universities. It continues to produce order-made software for cutting-edge research.

I started working as a systems engineer there, and in 2006 was appointed Representative Director. We concluded joint research and development contracts that went beyond order-made contract development, and also commercialized the research seeds to provide them to society. This work involved taking ideas for which patents had been acquired but that were lying dormant, and bringing them to the world. Our stance of commercializing research seeds and bringing them to society was highly evaluated, and we were frequently asked “why do you not do the same thing with hardware?”

Then 11 years ago at the research exhibition “Technology Showcase” of the Science Academy of Tsukuba, I met Shinichi Ikeda who was a Chief Senior Researcher at the National Institute of Advanced Industrial Science and Technology (AIST). Mr. Ikeda had received the Best Idea Award for a technical presentation regarding optical heating, and he expressed that “he wanted optical heating technology to be applied to produce products that are useful for society, and to bring them to the world”. Up to that time Penguin Systems had undertaken several projects for AIST, but I thought that in order to deal with hardware properly it was necessary to establish a company organization. In addition, I was convinced that the time had come for a fusion of software and hardware, and that there were opportunities for innovation and business with this combination. With these two ideas as the impulse, in 2010 the company was established with Mr. Ikeda as Technical Consultant (at the time of founding the name was Idea Co., Ltd., and in 2019 this was changed to the present name).

― Since then the coming of the age of fusion between software and hardware has accelerated, particularly with the IoT, hasn’t it?

I think the judgment of timing was correct. In the first phase of establishment of the company we confronted the issues of the necessity for space to install the equipment necessary for increasing the scale of development, and securing development staff, etc. In the second phase we undertook the formal AIST technology transfer venture procedures, and received our corporate name. Our development office was newly established in AIST Tsukuba West where development was speeded up, and we worked on the commercialization of devices that apply optical heating technology and devices related to smell.

Application of optical heating technology to processing of medical waste, and extension to the market for smell also

― What is optical heating technology?

It is an old technology with the basic principle that when light is incident on an object it is converted into heat, and the object is heated. To make this simple principle more efficient, technologies such as focusing with reflective mirrors are frequently used.

The greatest merit is that by focusing the light onto a point with reflective mirrors, high temperatures can be realized with small energy. For example, high temperatures of 1,500°C can be achieved with about 500 W. Also, its strengths are that heating is possible even with no contact or in a vacuum, the cost of introduction and operation is low, and the heating effect on the surroundings is small.

― What are your ideas regarding fields of application of the technology and its deployment?

First, fields where it is already being applied include thin films processed in the manufacture of semiconductors, soldering, etc. It can be seen from the fields where it is already being used that optical heating has particular applications to which it is suited. Light is converted into heat on the surface of an object, so it is not suitable for objects with too much thickness. Conversely the technology has great strengths for applications where the surface only is heated and the interior is not heated. We are gradually exploring fields of application that can utilize these properties.

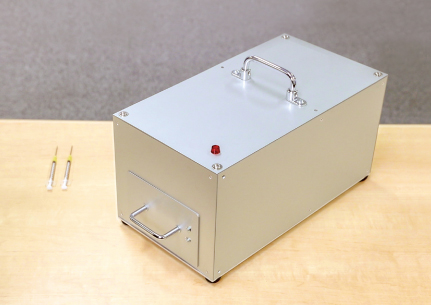

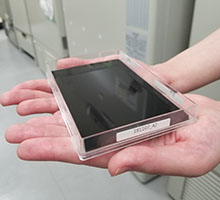

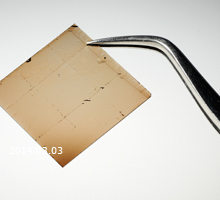

For starters we have applied the technology to a device “Hikari” that renders used syringes harmless by fusion, as our own company’s product. This is a device that melts used syringes on the spot, rendering them harmless. Using the principle of focused optical heating, the high temperatures necessary for melting the needles of syringes are achieved in an energy efficient manner. In addition at the same time it has the function of melting and rendering harmless not only the needle, but also the plastic parts of syringes. Processing the needle only can be performed by existing products of other companies, but there was no device that could simultaneously process the syringe also.

Actually Mr. Ikeda had already produced a prototype that applied optical heating technology. However the format was to process the whole syringe using reflective mirrors, so the device was large. “Hikari” achieves simultaneous processing of needle and syringe using a new method for which a patent application has been submitted. It has the strengths that the time required to process one syringe is reduced from 1 minute to 10 seconds, the size of the device has been reduced so that it can be carried around, and its operation is simple. The performance of rendering the syringes harmless after processing has been examined by a third party organization, that confirmed that the syringes had been rendered 99.9999% harmless.

Device for rendering used syringes harmless by fusion, “Hikari”

In about 10 seconds both the needle and the syringe can be simultaneously rendered harmless by fusion

In normal hospitals in urban areas recycling is carried out by a recycling company, so there is little necessity for this device. However the product was developed for use on islands, in mountainous areas, in areas affected by a pandemic or a natural disaster, in developing countries, etc. The product has the advantages of solving problems of secondary infection in which a nurse pricks his- or herself accidentally with a used syringe, and prevention of dispersion of pathogenic bacteria as a result of long term storage of used syringes. At present we are in talks with various organizations regarding future deployment.

― Tell us about the other technology, the device relating to smells.

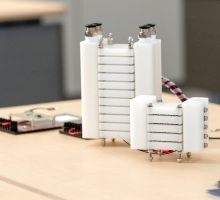

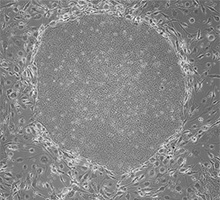

The opportunity for this development arose when I was introduced to Tatsu Kobayakawa, a Chief Senior Researcher at AIST, by a person in a prefectural industrial support department. This was at a time that he had produced a prototype in order to bring his research results to the world, and he was looking for a company that could commercialize it and bring it to the market. We participated in the design, parts procurement, development of prototypes, etc., in cooperation with several manufacturing companies that were member companies of Ibaraki R&D Association (abbreviation: IRDA) together with Penguin Systems and of which I was Representative of the Board of Directors. In this way we produced a smell testing device as a product.

Smell impairment testing is a medical procedure in which paper that has been immersed in measurement liquid is shaken in front of the nose for the test subject to smell. This very analog method has been in use for several tens of years. A device for performing this test has been produced and we have commenced the necessary procedures to bring it to the public, so that it can be used in precise tests for investigating the problems.

Applications in medical treatment are proceeding led by Penguin Systems, and we are pursuing needs for generating smells in fields other than medical treatment. The device can be custom-made for the type of smell, and for controlling the level of concentration. We provide devices for generating smells that do not affect the surrounding environment, and that can produce any smell at the desired timing while controlling the concentration.

Compared with the other five senses, the sense of smell is a field where there has been no progress in application and use in the market. We will deploy these products as more and more needs that are identified, for example confirmatory tests for smells generated by industrial products, the relationship between taste and smell, etc.

Smell testing device

Becoming the interface between research seeds and market needs

― What do you consider to be important as the driving force for your business?

The probability that various researches and developments will actually be provided to and be of use to the public is certainly not high. To date we have provided feedback to research institutes and universities through the technologies commercialized in our contract work and the products we have delivered, and by producing products by joint research and development. In this work we have felt a large gulf between researchers and the market. In the software field Penguin Systems provides a business that is a bridge between research seeds and the needs of the public, but we also want to provide this business in the hardware field. That is our company’s ideal. Our mission is to produce devices that realize ideas and technologies that are probably lying dormant in researchers’ drawers, and to bring them to the public. In this respect we are probably different from venture companies.

― What issues do you have regarding business expansion and what is your vision for the future?

The first pillar of our business is “commercialization of seeds”, and we want to develop new devices in the research and development field. As actual examples of “commercialization of seeds”, there are two other pillars: the second pillar is the business of applying optical heating technology, and the third pillar is the smell generating device business, that we want to further promote. In particular regarding the latter two, we are finally in the phase of full-scale manufacture and sale, and in this phase there are two issues regarding promotion of the business. The first is the financial aspect. Manufacturing devices entails up front materials costs, external processing costs, transport costs, etc., in addition to personnel costs, so it is necessary to procure finance. The other issue is expanding and strengthening human resources. Increasing the speed of development is essential for constructing new fourth and fifth pillars, so this is where we are placing our efforts together with procurement of finance.

However, we do not want to unreasonably expand the scale of our business or the company. Instead what we want to do is expand the scale of the market, so that when we bring an unprecedented product to the world such as for example devices related to smell, they become necessary and are used throughout the world. Above all we are a company that specializes in development and we intend to proceed with this image in mind.

* The contents of this article are based on information as of March 31, 2019.

ペンギンインストゥルメンツ株式会社

本社:〒305-0047 茨城県つくば市千現2-1-6 つくば研究支援センター CB9

開発室:〒305-8569 茨城県つくば市小野川16-1 国立研究開発法人 産業技術総合研究所 西事業所内

医療事業推進拠点:〒650-0047 兵庫県神戸市中央区港島南町1-6-5 国際医療開発センター(IMDA)内

Penguin Instruments Inc.

2-1-6 Sengen, Tsukuba City, Ibaraki Prefecture, Japan 305-0047

Research Institute for Earth Science Visualization Technology Co.,Ltd.

Visualizing the History of the Earth, and Creating a “Museum of the Future”!

- Precision 3D Modeling and Projection Mapping –

Mottainai Energy Co., Ltd.

Brightening the Future with Electricity Produced from Heat!

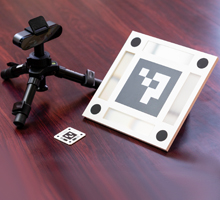

LEAG Solutions Corporation

New image measurement for the smart society!

- 3D position and attitude measurement using high-accuracy markers -

HikariPath Communications Co., Ltd.

Realtime 4K video eliminates distance using new optical communication technology!

Trimatiz Limited

Manipulating light to open up the future! Technology for measuring the unknown underwater world

Nanolux co. ltd.

Deliver Color Images in Darkness! Unique Technology Enabling Color Image only by Infrared Illumination

SteraVision Co.,Ltd.

Realizing an Eye that can See like a Human!

– Development of Optical Steering Device and New Standard Lidar -

ProteoBridge Corporation

Reproduce human on the palm !

-Development of the world's first human protein array-

Site Sensing Inc.

Expanding a New Business with Excellent Measurement Technologies for Tracking, 3D Modeling , and Face Recognition

Hmcomm Inc.

Controlling Voice to Open Up Next Generation Business!

- Commercializing AI and Voice Recognition Technology -

TOKIWA-Bio Inc.

Automatic Generation of iPS Cells!

- Contributing to Gene Therapy Worldwide -

HSP Technologies Inc.

Producing New Materials by Mixing Materials that do can not Mix!

MIRAISENS,Inc.

A feeling as if things were really there!

~ Digitization of physicality and bodily sensations ~

PicoTherm Corporation

Supporting information society by technology to measure thermophysical properties

EDP Co.

Dedication to the ultimate material, diamond