TECH Meets BUSINESS

Currently, electronic devices, such as computers and cell phones, are so refined that performance degradation becomes a concern even when subtle heating occurs. The importance of measuring how easily heat from individual materials is transferred will be increasingly recognized from now on.

President and CEO of PicoTherm Corporation. At NEC, she was engaged in the development of thermal control systems for artificial satellites and experimental equipment for zero-gravity environments. After that, she was involved in planning and production at a publisher and an art center, and then, she joined AIST. She conducted a task force project for starting companies, and she founded PicoTherm Corporation in 2008.

I was able to commercialize attractive technologies after I joined AIST.

-- First, would you tell me about yourself before joining AIST?

My major at the University of Tsukuba was particle physics. After graduation, I joined NEC and I was engaged in the development of experimental equipment for high-temperature melts in a zero-gravity environment, at the Space Development Division, to which I was assigned. Loading experimental equipment into a small aircraft, we experimented in a microgravity environment for about 20 seconds, during a ballistic flight. Finally, loading that equipment onto a small-sized rocket TR-1A, we launched it from Tanegashima Space Center. That was a success, and we gained valuable experience. After that, I worked on the development of thermal control systems for artificial satellites. Satellites are exposed to a severe thermal environment in space; thus, thermal design and thermal simulations are very important. I was engaged in the design and development of thermal control systems for broadcasting satellites and weather satellites.

-- I heard that you got a job in art after that.

Ishikawa:Yes, I was interested in various things. Therefore, I learned art at a design school and worked on planning and production at a publisher and an art center.

-- Then, you got a job at AIST, right?

Ishikawa:In 2005, I started working at the Thermophysical Properties Section in Metrology Institute of Japan in AIST. In 2006, I applied for a task force with Dr. Baba, who was my manager at that time, and we were selected. Since then, I was engaged in the implementation of instruments for two years.

-- What preparations had you been making during the two years before the company startup?

Ishikawa:First, we aimed to develop a prototype. The national standard instrument for evaluating the thermophysical properties of thin films at AIST was a substantially large system. The key point for implementation was miniaturization. We focused on how to miniaturize the instrument and lower its cost, maintaining the national standard. At the same time, we also performed marketing research by attending exhibitions, and holding workshops and international conferences. Two years later, a prototype “NanoTR” was completed. In 2008, I founded PicoTherm Corporation, and we started providing analytical services.

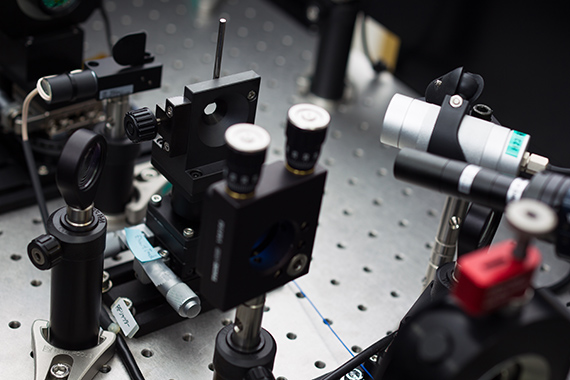

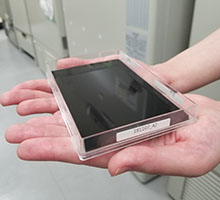

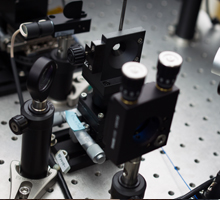

One of the major products, the thermophysical property measurement instrument for thin films, PicoTR, where a picosecond thermoreflectance method is used.

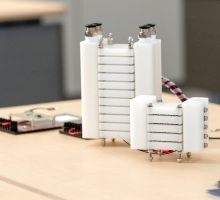

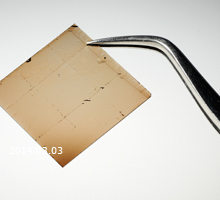

Another major product, NanoTR. It is characterized by a compact chassis. Technological Innovation

Owing to miniaturization and a high degree of integration of electronic parts, there is a growing need for the measurement of the thermophysical properties of thin films.

-- Next, I would like to ask about the major products of PicoTherm Corporation. What is the basic technology, “a pulsed light heating thermoreflectance method”?

Ishikawa:It is a technology, developed at AIST, to measure the thermophysical properties of thin films. In the pulsed light heating thermoreflectance method, first, the thin film being measured is irradiated with a high-speed pulsed laser with a time duration of a picosecond (one trillionth of a second) or a nanosecond (one billionth of a second) to instantly heat the thin film. Heat is transferred during the heating stage, and the temperature of the thin film increases. Then, a pulsed laser is used to irradiate that heated part to measure the temperature. The intensity of the reflected light of the temperature-measuring laser varies depending on the temperature of the surface of the thin film. In this method, measuring the variation of that intensity enables us to estimate the time interval during which heat is diffused in the thin film, then we can obtain the value of the thermophysical property. There are two types of pulsed light heating thermoreflectance methods. One is the RF method, in which a thin film is heated from behind and the front side is irradiated using the temperature measuring light, and the other is the FF method, in which a thin film is heated from the front side and the same position is irradiated using the temperature measuring light. Incorporating both the RF and FF methods in an instrument enables us to measure a thin film on any substrate. In particular, the RF method is stipulated in the JIS standard.

-- In the first place, what are thermophysical properties?

Ishikawa:Simply speaking, they indicate the property of a material to transfer heat is transferred. In the past, there were cases in which the performance was degraded, or in the worst case, fire occurred, by the heat generated in a battery or a personal computer, and the causes for those were thermal design. Nowadays, at product development sites, development is carried out to achieve high speed, small size, low power consumption, and low cost. On the other hand, problems because of heating, such as breakdowns, malfunction, and a short lifetime, become serious. That is why, even at the development phase, simulations are required to predict heat generation and heat transfer needs to be managed by design. In particular, to have accurate thermal design and to conduct accurate thermal simulations, it is essential to measure the thermophysical properties and to use accurate data.

-- In product development, to what kinds of products is the measurement of thermophysical properties being applied?

Ishikawa:Thin films are used in various fields. For example, CDs and DVDs are composed of laminated thin films, and thin films are also used in flat panel displays, such as liquid crystal displays and OEL displays, which are used in TVs, PCs, and cell phones. Nowadays, instead of making films much thinner, films and patterns that are much smaller are often used, but for thin films, measurement is essential because their thermophysical properties vary depending on film manufacturing methods, defects in crystals, and contamination by impurities.

-- There are two products: one is PicoTR, of which the time resolution is in picoseconds, and the other is NanoTR, with a time resolution of nanoseconds. What are the differences between these two?

Ishikawa:The functions of instruments and the items that are measured are almost the same in the two products, but which instrument to use depends on the thickness of the thin film that is being measured. If the thickness of a thin film material is around several micrometers, measurement can be sufficiently performed using NanoTR, of which the time resolution is one nanosecond. If we need to measure a much thinner thin film, we can use PicoTR, of which the time resolution is one picosecond. The instrument enables us to measure a thin film material with a thickness ranging from several tens of nanometers to several hundred nanometers.

Inside of PicoTR. State-of-the-art technologies are integrated, and it looks like a street of office buildings.

We aim to distribute our instruments worldwide so that they are widely used.

-- To what fields do you expect these products to be applied in future?

Ishikawa:Evaluation of thermophysical properties is needed in various fields such as countermeasures against heat generation associated with high integration of semiconductor devices, densification of optical heating phase transition type recording media, high efficiency of thermoelectric devices, implementation of high-brightness LED lamps, and the high-temperature operation of power devices. While various manufacturers compete with each other in the development of new materials, which leads to the development of products that are superior to conventional products in terms of performance, I think that thermal management will play an important role from now on.

-- Lastly, tell me about the future prospects of PicoTherm Corporation.

Ishikawa:Fortunately, we received an Excellence Award (Rose Award) at the Joyo Business Awards in the last year they were awarded (2013), and we became a finalist at the 2nd DBJ New Business Plan Competition for Women Entrepreneurs. The world’s first products that enable highly accurate measurements of thermophysical properties of thin films are instruments needed not only in Japan, but also in the rest of the world, so we would like to promote sales of those products in overseas countries from now on. Then, I hope we would be able to distribute our products so that measurements by using PicoTR and NanoTR become a de facto standard in the world. This is a niche field, but this is an important technology to support the social infrastructure. In the global competition of technology development, we would like to widely contribute to society so that we can provide “thermal solutions,” aiming at measurement and evaluation that are useful for product development.

* The contents of this article are based on information as of July 16th, 2014.

Research Institute for Earth Science Visualization Technology Co.,Ltd.

Visualizing the History of the Earth, and Creating a “Museum of the Future”!

- Precision 3D Modeling and Projection Mapping –

Mottainai Energy Co., Ltd.

Brightening the Future with Electricity Produced from Heat!

LEAG Solutions Corporation

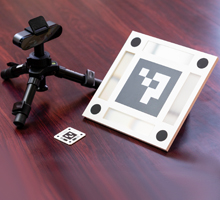

New image measurement for the smart society!

- 3D position and attitude measurement using high-accuracy markers -

HikariPath Communications Co., Ltd.

Realtime 4K video eliminates distance using new optical communication technology!

Trimatiz Limited

Manipulating light to open up the future! Technology for measuring the unknown underwater world

Nanolux co. ltd.

Deliver Color Images in Darkness! Unique Technology Enabling Color Image only by Infrared Illumination

SteraVision Co.,Ltd.

Realizing an Eye that can See like a Human!

– Development of Optical Steering Device and New Standard Lidar -

ProteoBridge Corporation

Reproduce human on the palm !

-Development of the world's first human protein array-

Site Sensing Inc.

Expanding a New Business with Excellent Measurement Technologies for Tracking, 3D Modeling , and Face Recognition

Hmcomm Inc.

Controlling Voice to Open Up Next Generation Business!

- Commercializing AI and Voice Recognition Technology -

TOKIWA-Bio Inc.

Automatic Generation of iPS Cells!

- Contributing to Gene Therapy Worldwide -

HSP Technologies Inc.

Producing New Materials by Mixing Materials that do can not Mix!

MIRAISENS,Inc.

A feeling as if things were really there!

~ Digitization of physicality and bodily sensations ~

PicoTherm Corporation

Supporting information society by technology to measure thermophysical properties

EDP Co.

Dedication to the ultimate material, diamond