TECH Meets BUSINESS

Mottainai Energy Co., Ltd. is undertaking development based on the results of the Thermoelectric Energy Conversion Group of AIST. In the field of thermoelectric power generation in which waste heat is converted into electricity, in addition to materials development and modularization, they perform measurement and evaluation using original instruments, and provide innovative applied products. They propose further expansion and propagation of thermoelectric power generation utilizing a broad range of knowledge cultivated in the thermoelectric field.

Representative Director and CEO of Mottainai Energy Co., Ltd. He completed his master's degree at Japan Advanced Institute of Science and Technology in September 2003. From October 2003 until March 2010 he worked at Ferrotec Holdings Corporation, from April 2010 until March 2011 he worked at the Japan Research Industries and Industrial Technology Association (assigned to: National Institute of Advanced Industrial Science and Technology), and from April 2011 he has been employed by the National Institute of Advanced Industrial Science and Technology. Between April 2013 and March 2014 he worked with the National Institute for Materials Science, then in June 2016 he established Mottainai Energy Co., Ltd., and became its Representative Director. From June 2018 he has been a coordinator at the Research Institute for Ambientronics of Waseda University.

Starting from a fateful encounter, research into “thermoelectric power generation” and start-up

― What brought you into the field of thermoelectric power generation?

I first became involved in thermal electric power generation when I was at graduate school. The roots of the research laboratory that I belonged to in my university days was the first group in Japan to research thermoelectric conversion technology, although I did not know this at the time and only found out later. In addition, I later heard that my older brother had been in the thermoelectric power generation field and had carried out joint research with Professor Nishida, who was at the semiconductor products company Ferrotec Holdings Corporation. He was there about until several months before I joined the company. Such fateful encounters happened, and I moved to a company that made thermoelectric modules, and I decided that I wanted to thrive in this field.

― Can you describe the events up until the establishment of Mottainai Energy Co., Ltd.?

During my 20s when I was in private sector companies, I obtained a wide range of work and experience not only in technical development but also in management planning such as intellectual property strategy, information on other companies, etc. However I felt that I had reached a dead end and that I could not grow farther, so when I was 30 years old I joined AIST. I was undertaking basic research, but it was at that time that the Great East Japan Earthquake occurred. Both my boss and I felt again that there was nothing that we could do, and that basic research on its own would not lead to research that is useful for society. I felt that if we did not put our efforts into applied products this field could not expand.

I knew that AIST had a system in which after developing an applied product, the technology is transferred to a venture company. Therefore I established the company so that I could sell the products myself and expand the field. It is a tale of utilizing the wide range of experience and know-how that I have cultivated to find the most effective method, prompted by my encounters with the people I have met to date.

Providing measuring instruments in response to needs, and developing applied products with excellent power generation and cost performance

― Can you describe your company’s strengths with thermoelectric conversion technology as the background?

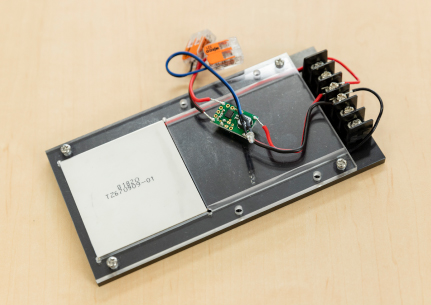

First, thermoelectric conversion technology is a combination of two technologies: the Peltier effect which produces a flow of heat (temperature difference) by passing a current, and the opposite principle, the Seebeck effect that produces a voltage when the temperature difference (flow of heat) is applied. In particular in the case of the latter electricity can be obtained by connecting a load, so it is referred to as thermoelectric power generation. We have 4 businesses based on this thermoelectric conversion technology, namely materials, modules, devices, and applied products.

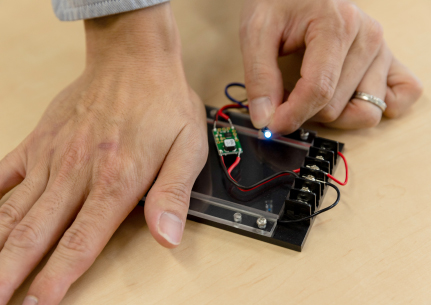

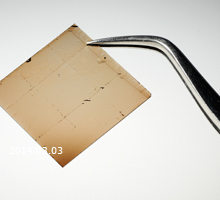

The LED lights up when the palm of a hand is placed on a thermoelectric module due to thermoelectric power generation

Thermoelectric power generation has a history of nearly 200 years, but many factors are insufficient, such as the materials from which performance can be obtained at room temperature have not changed greatly in almost 70 years, the technologies for measurement and evaluation have not matured, the market scale is small, etc. At our company we undertake all work in connection with the thermoelectric field, utilizing synergies such as the materials research I was involved in at AIST, experience of modularization from private sector companies, work related to measurement and evaluation, etc.

For example we do not specialize in just applied products, but we also provide devices for investigating performance to customers that have their own materials, and provide advice on modularization of materials. We are also engaged in development of applied products aimed outside the field, while progressing with basic research and development in this field. Our style is to contribute to the development of this field through these two approaches, and to prepare the market for accepting applied products. Our strength is that we can follow these approaches through the wide-ranging experience that we have accumulated.

― Of your 4 businesses, can you describe the “devices” and the “applied products” that have been commercialized?

In the devices business, we carry out both contract measurement related to thermoelectric power generation, and sale of measuring instruments. In our sales, we handle the high-performance resistance distribution measuring instruments developed by AIST for precise investigation into whether or not the electrical resistance of the material is uniform or not. In addition, we produce original instruments based on the requirements of our customers. For example, a researcher that was developing thin films such as thin paper as a thermoelectric material was unable to take measurements with existing instruments. An instrument that suited the need was required but there was no manufacturer capable of supplying it. As a result there is no increase in the number of new players. The devices business supports materials development and modularization, to heat up the market.

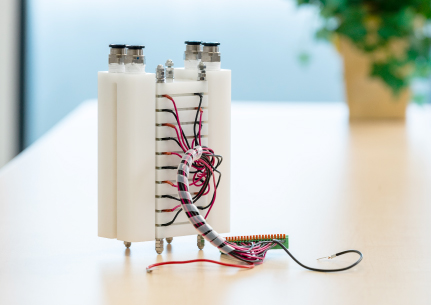

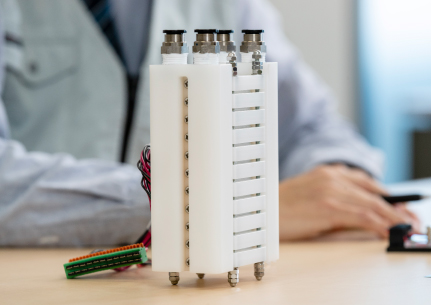

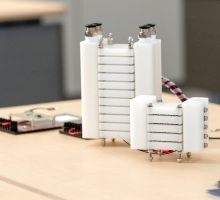

A stack type thermoelectric power generation unit is an applied product that uses power generation technology during heat exchange between hot and cold water. Water channels are formed so that the hot water and cold water flow in opposite directions, and a thermoelectric module is incorporated on the front and rear. In the case of a 10 stack product, the power generation when the temperature difference is 85C is 10 W, and the power density achieved is a remarkable 12 kW/m3. The modules can be stacked and arranged, so they can be used even in limited installation areas, and they can constantly generate electrical power provided there is a temperature difference. For example solar power generation panels with a conversion efficiency in excess of 20% require a large area such as a roof, and their availability factor which is affected by daylight hours and the weather is about 15%. In contrast the conversion efficiency of the thermoelectric power generation unit is only 2 to 3%, but it can achieve an availability factor of 90%, so it can compete in terms of generated watt-hours (Wh).

Stack type thermoelectric power generation unit (10 stack product)

The compact body is made from engineering plastics

Also, another point is that the body is made from plastic. There is a tendency to think that metal is more suitable in terms of generation of electricity through heat, and actually similar products made by other companies use a metal such as stainless steel. However with a change in concept our product uses a new heat exchange mechanism in which the power generation capacity is not reduced even with engineering plastics having low thermal conductivity. Also with plastics the cost can be reduced, and this is a core technology that had not been envisaged by anyone in the long history of thermoelectric power generation.

Cost performance is given as the reason why the thermoelectric power generation market has not expanded. There is a divergence between the cost of introduction in the denominator, and the power generation or value that can be provided in the numerator. Based on the fact that high cost is the main problem, in our development of applied products we of course are improving the performance, but our strength is that we are mainly focused on cost reduction. Our main avenues for expansion include local governments and factories in hot spring areas.

The key is creating new ideas for exploiting the thermoelectric power generation market

― Can you describe your vision for the future expansion of the business?

Our vision for the future as I have mentioned before is for the business of materials, modules, and devices for the industry, and the business of applied products that can be delivered to the industry revolving like two wheels. There is momentum in the world from the recent interest in renewable energy, and society perceives the need for electrical power generation. However, it is a problem to lose the work when the trend passes. Applied products are essential for recognition of thermoelectric power generation.

For example I think that an electronic calculator with solar power generation is one good example of product. The fact that when it is bright it operates instead of a battery can be accepted even by children who do not understand the principle. Likewise it is essential to provide applied products in order to raise the level of recognition, so that people will know that it is thermoelectric power generation even if they do not understand the principle. I consider that the business of proposing original products is important for bringing to the world applied products using thermoelectric power generation that achieve cost performance.

― It seems that thinking outside the box is important, isn’t it?

It is necessary to increase the number of people that produce ideas, such as putting a function that produces interesting movements and sounds in a toy by using the temperature difference between the body temperature of a child and the external air, etc. The work of producing applied products jointly with partner companies will be extremely important in the future while giving the industry such devices and stimuli. At that time how the cost performance is perceived will be the key to expansion of thermoelectric power generation. The concept is a business that creates ideas and services in accordance with the times, while of course stressing the importance of improvement in the base technologies.

Materials and modules can be completed by just researchers or developers. As I look back on what I have received from my older brother and, the Professor, and all the experience I received at companies, if I stopped here I would have a feeling of guilt towards the industry. Therefore I want to complete this work with a sense of “mission” or “destiny” rather than “fate". In the future I want to expand the scale of the thermoelectric power generation market which is still small. * The contents of this article are based on information as of March 31, 2019.

* The contents of this article are based on information as of March 31, 2019.

株式会社モッタイナイ・エナジー

〒305-0047 茨城県つくば市千現2-1-6 つくば研究支援センターC棟

Mottainai Energy Co., Ltd.

2-1-6 Sengen, Tsukuba City, Ibaraki Prefecture, Japan 305-0047

Research Institute for Earth Science Visualization Technology Co.,Ltd.

Visualizing the History of the Earth, and Creating a “Museum of the Future”!

- Precision 3D Modeling and Projection Mapping –

Mottainai Energy Co., Ltd.

Brightening the Future with Electricity Produced from Heat!

LEAG Solutions Corporation

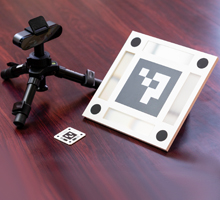

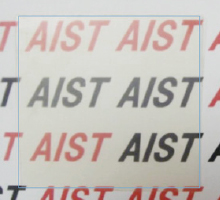

New image measurement for the smart society!

- 3D position and attitude measurement using high-accuracy markers -

HikariPath Communications Co., Ltd.

Realtime 4K video eliminates distance using new optical communication technology!

Trimatiz Limited

Manipulating light to open up the future! Technology for measuring the unknown underwater world

Nanolux co. ltd.

Deliver Color Images in Darkness! Unique Technology Enabling Color Image only by Infrared Illumination

SteraVision Co.,Ltd.

Realizing an Eye that can See like a Human!

– Development of Optical Steering Device and New Standard Lidar -

ProteoBridge Corporation

Reproduce human on the palm !

-Development of the world's first human protein array-

Site Sensing Inc.

Expanding a New Business with Excellent Measurement Technologies for Tracking, 3D Modeling , and Face Recognition

Hmcomm Inc.

Controlling Voice to Open Up Next Generation Business!

- Commercializing AI and Voice Recognition Technology -

TOKIWA-Bio Inc.

Automatic Generation of iPS Cells!

- Contributing to Gene Therapy Worldwide -

HSP Technologies Inc.

Producing New Materials by Mixing Materials that do can not Mix!

MIRAISENS,Inc.

A feeling as if things were really there!

~ Digitization of physicality and bodily sensations ~

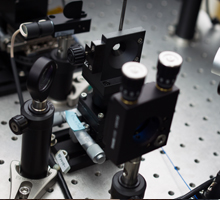

PicoTherm Corporation

Supporting information society by technology to measure thermophysical properties

EDP Co.

Dedication to the ultimate material, diamond