300mm Processing Platform Research TeamAbout

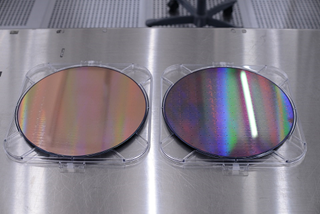

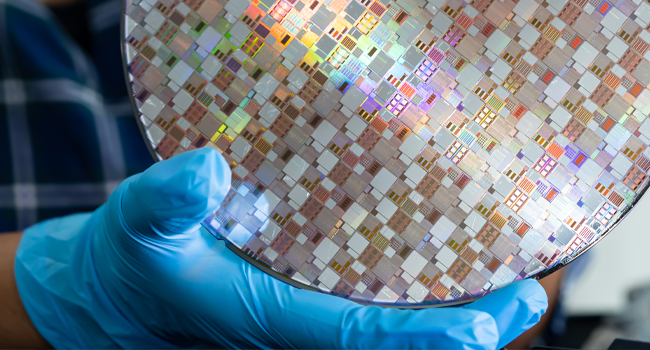

Open innovation for semiconductor manufacturing processes dealing with 300 mm silicon wafers

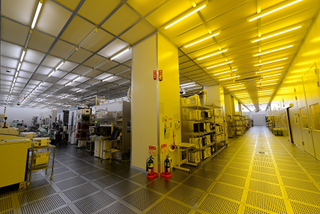

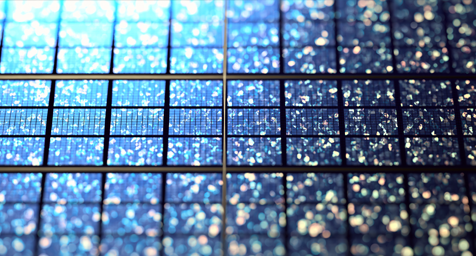

We work on open innovation for semiconductors. We engage in AIST’s advanced semiconductor projects as well as the fabrication services for the requests from organizations outside AIST. Our facility is operated under the clean conditions and metal contamination controls, which are equivalent to those of a mass-production semiconductor factory using 300 mm silicon wafers. CMOS devices, silicon photonics devices, and Cu-wiring structures are fabricated on our process platform.