Structural and Processing Reliability Group

We will contribute to the enhancement of industrial competitiveness by creating databases and bridging technology to industry.

About

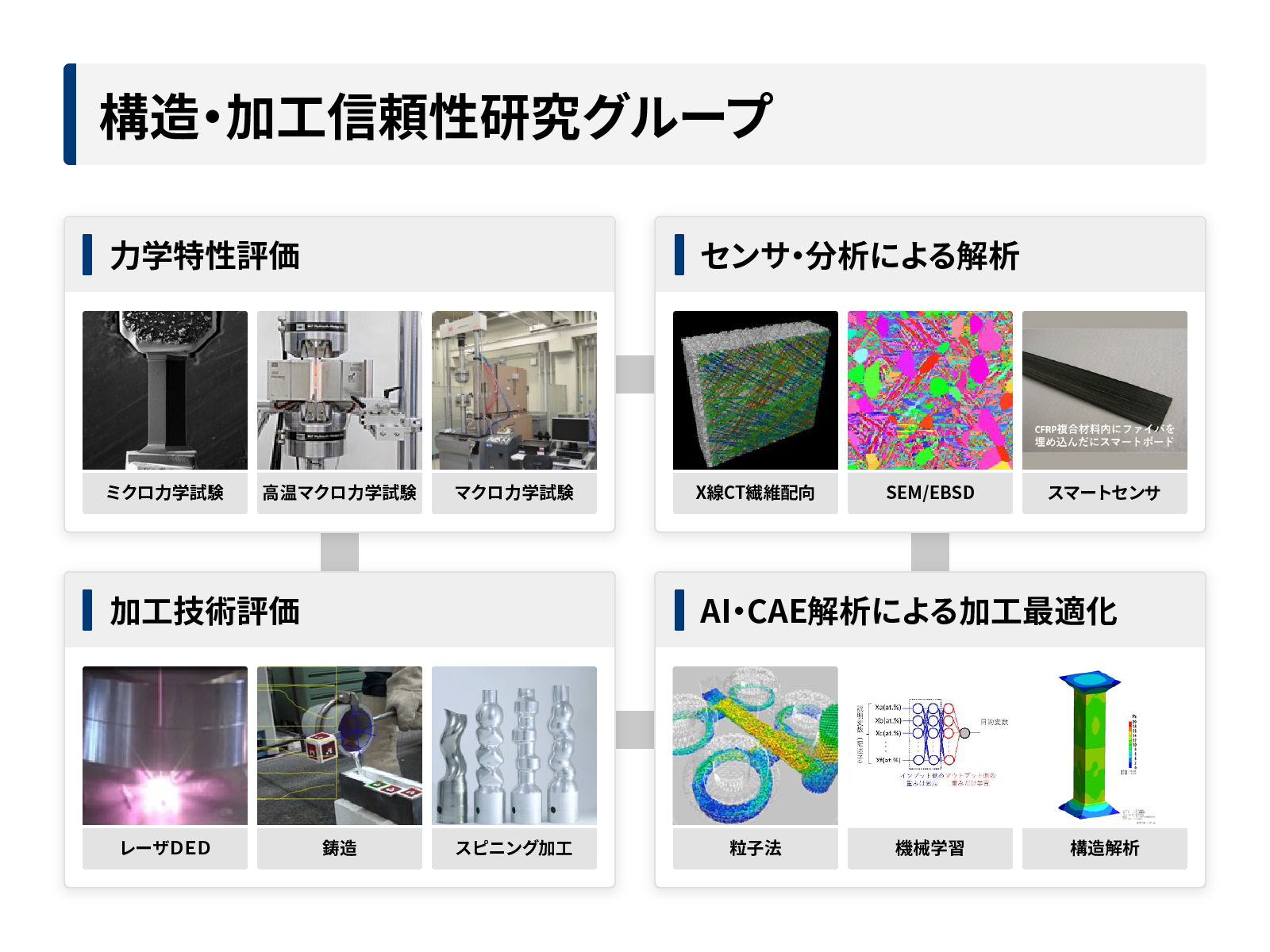

The Structural and Processing Reliability Group conducts research and development on the reliability of structural materials and material processing used in transportation and industrial applications. We work on the topics of: "mechanical reliability of materials", "microstructural evaluation", "processing optimization using simulation of finite element method, particle methods and machine learning", and "reliability enhancement of advanced processes such as plastic forming, casting, additive manufacturing, surface treatment and impact process". In addition, it aims at the contribution of the industrial competitiveness to strengthening by making of these results a database, and mediating the technology to the industrial field.

Keywords

Plastic forming, Casting, Surface treatment, Machine learning, process simulation, microstructure, mechanical properties

Points

- 1Reliability of materials

- 2Processing optimization using simulation

- 3Reliability enhancement of advanced processes

The Structural and Processing Reliability Group conducts research and development on the reliability of structural materials and material processing used in transportation and industrial applications.We work on the three pillars of "reliability of materials", "processing optimization using simulation" and "reliability enhancement of advanced processes".

・Mechanical reliability such as strength and fatigue, microstructural evaluation by deformation and processing

・Processing optimization through machine learning and simulation

・Improve reliability of advanced processing technologies such as plastic forming, casting, additive manufacturing, surface treatment, and impact process

We are working to create high value-added products and technologies.

Subjects

-

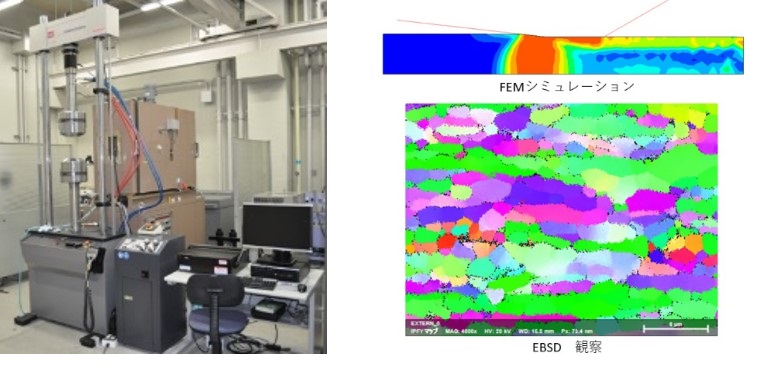

1.Reliability of materials

In order to evaluate the reliability of materials and processing, it is necessary to measure the mechanical properties and deformation structures of materials. Therefore, we are clarifying the deformation, fracture, and processing mechanisms by incorporating strength and life evaluation of processed materials and analysis of microstructural changes due to deformation.

-

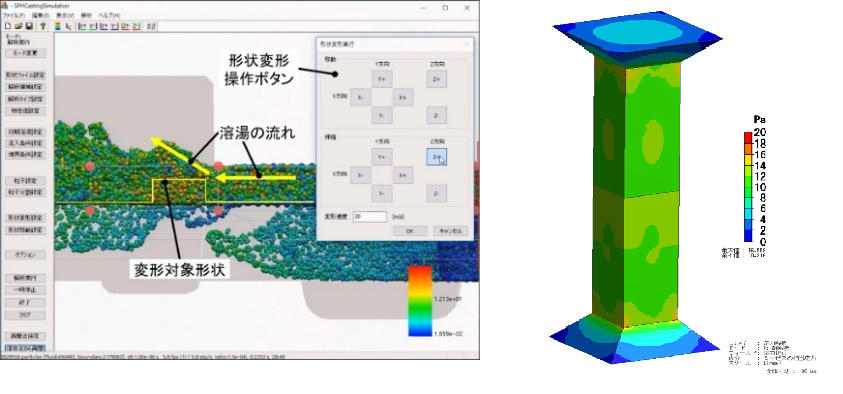

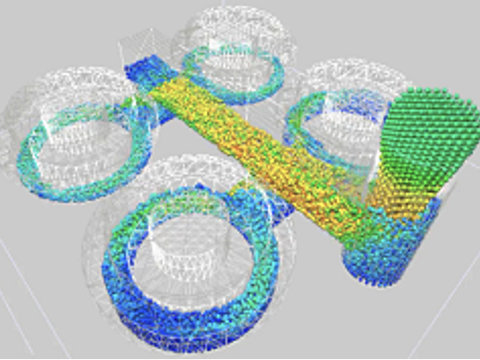

2.Processing optimization using simulation

In the processing processes of plastic forming, casting, joining, and surface treatment, we are conducting research on processing optimization using various simulation such as finite element analysis and particle method, and machine learning.

-

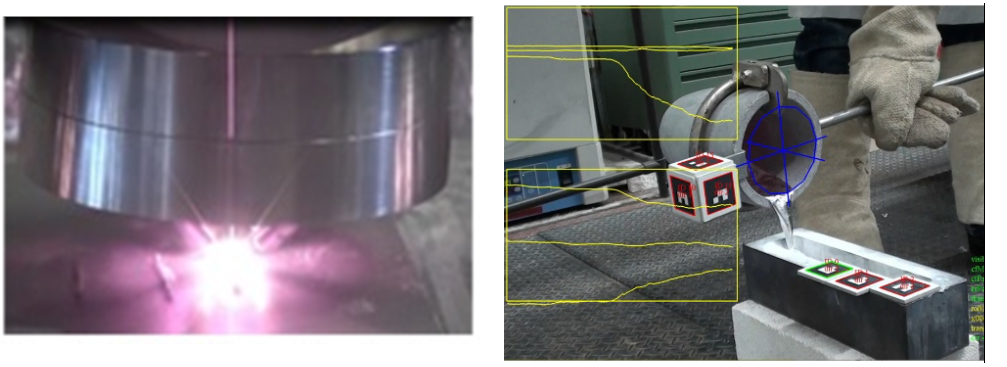

3.Improve reliability of advanced processing technologies

A wide variety of structural materials have been used in transportation and industrial application, and processing technology suitable for these materials is required.We are conducting research and development aiming at improving the reliability of processing related to advanced processing technologies such as plastic forming, casting, additive manufacturing, surface treatment and impact process.

Themes

-

Mechanical reliability of structural materials and processing materials

It is necessary to use composite materials of lightweight and high rigidity

for lightening and low fuel consumption of transport applications. The

technology that the mechanical properties and the fatigue lifetime estimation

of materials, its bonding and joints is developed.

View More

It is necessary to use composite materials of lightweight and high rigidity

for lightening and low fuel consumption of transport applications. The

technology that the mechanical properties and the fatigue lifetime estimation

of materials, its bonding and joints is developed.

View More

-

Development of casting simulation using particle method

Thermal flow/solidification simulationCastingCasting plan

In casting, the behavior of the molten metal in the mold has a great impact on product quality. In this research, using the particle method, we are developing simulations of phenomena that are difficult to predict with conventional methods that combine thermal flow, solidification, and defect formation.

In casting, the behavior of the molten metal in the mold has a great impact on product quality. In this research, using the particle method, we are developing simulations of phenomena that are difficult to predict with conventional methods that combine thermal flow, solidification, and defect formation.

-

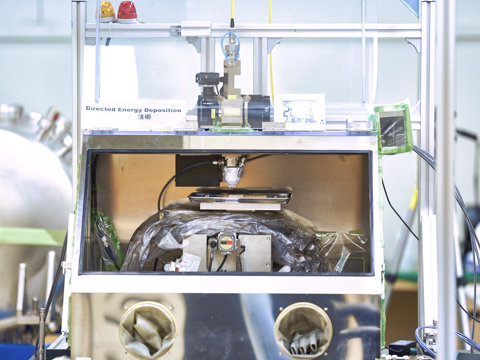

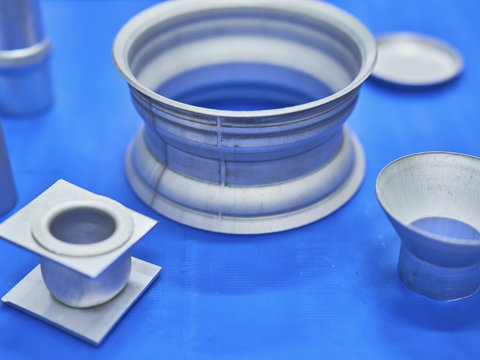

Development of processing technology by laser DED

DED would be more useful when more finer building part is realized. Our aim of research is development of more finer printer with high dimensional accracy and resolution.

View More

DED would be more useful when more finer building part is realized. Our aim of research is development of more finer printer with high dimensional accracy and resolution.

View More

-

Process informatics tool software tool of coating and surface treatment

Develpoment of coating software, named coating process infomatics tools, digitalized by expert's technological skill and knowledge.

View More

Develpoment of coating software, named coating process infomatics tools, digitalized by expert's technological skill and knowledge.

View More

-

Development of electromagnetic forming technology

We are researching technologies for forming light metals such as aluminum or joining dissimilar materials at high speeds using electromagnetic forces.

View More

We are researching technologies for forming light metals such as aluminum or joining dissimilar materials at high speeds using electromagnetic forces.

View More

-

Development of piezoelectric devices

Development of smart boards that can detect and suppress vibrations, development of composite functional fibers with four functions: shape memory effect, superelastic effect, piezoelectric effect, and pyroelectric effect, application to energy harvesting devices, etc.

View More

Development of smart boards that can detect and suppress vibrations, development of composite functional fibers with four functions: shape memory effect, superelastic effect, piezoelectric effect, and pyroelectric effect, application to energy harvesting devices, etc.

View More

-

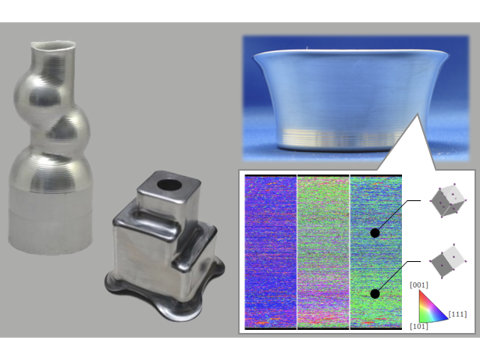

Improvement of spinning process by texture analysis and A.I.

SpinningRobot controlMicrostructureTextureMachnine learningA.I.

We introduced robot control technology and realized spinning process of complicated shapes. In order to achieve high-precision shape control and reduce the number of prototypes, we are working on clarifying the basic deformation process by texture analysis and extracting the optimum processing conditions using machine learning.

We introduced robot control technology and realized spinning process of complicated shapes. In order to achieve high-precision shape control and reduce the number of prototypes, we are working on clarifying the basic deformation process by texture analysis and extracting the optimum processing conditions using machine learning.

-

Development of melting and casting technology for casting difficult-to-form alloys

Matal castingCasting planHigh melting temperature alloySolidification structure

Difficult-to-form alloys are used in high-value components, but if they can be produced by casting, they can be used in a wider range of components. We are developing melting technology, special mould making technology, and casting plan technology suitable for difficult-to-form materials.

Difficult-to-form alloys are used in high-value components, but if they can be produced by casting, they can be used in a wider range of components. We are developing melting technology, special mould making technology, and casting plan technology suitable for difficult-to-form materials.