Tribology Group

Fundamental and innovative tribology toward social needs

About

Tribology is defined as "the science and technology of interacting surfaces in relative motion and of related subjects and practices" according to the glossary of the OECD. When objects slide each other, the surfaces (interfaces) move relatively, and the surfaces change from moment to moment due to friction and wear. There are various forms of friction, and tribology exists wherever objects move. The fact that tribology is regarded as a "the science and technology of practices" means that the problem of tribology is not an "ideal place", and it is necessary to proceed with research in consideration of actual movements, surfaces, environments, etc. We are conducting research while securing a broad perspective from basics to applications in order to respond to the diversity of the manufacturing industry, such as changes and uncertainties in social conditions and industrial structures expected in the future.

Keyword

Friction・Wear・Lubricarion・Maintenance・Machine Element・High Temperature Sliding Material・Cermet・Decarbonized Tribology System・Tribological Simulation・Surface Function

Points

- 1Ecological Tribology

- 2Functional Tribology

- 3Evaluation of Tribological Property

We are conducting research on "ecological tribology", "functional tribology", and "tribology evaluation" as priority topics. "Ecotribology" is a slightly old expression, but the impact of human activities on the global environment has not subsided and is becoming more serious. So we are working on the development of tribosystems that can deal with environmental and energy problems. "Functional tribology" gives functions to each of the three bodies related to tribology (two friction surfaces and a lubricant between them) to create a system that strongly supports increasingly sophisticated mechanical systems. "Tribology evaluation" involves correctly evaluating phenomena, examining whether the method can be used in research and development, and developing it into an international standard that can be used around the world.

Subjects

-

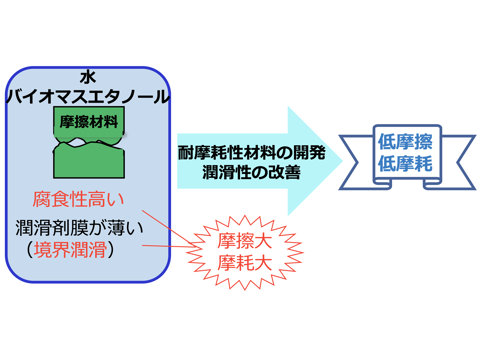

1.Ecological Tribology

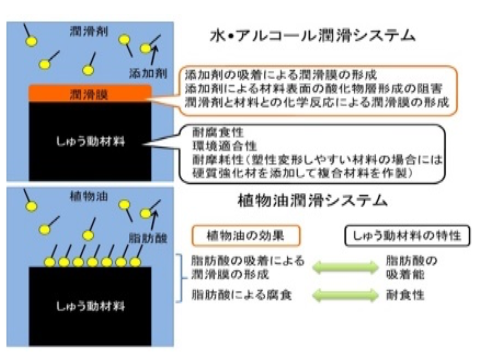

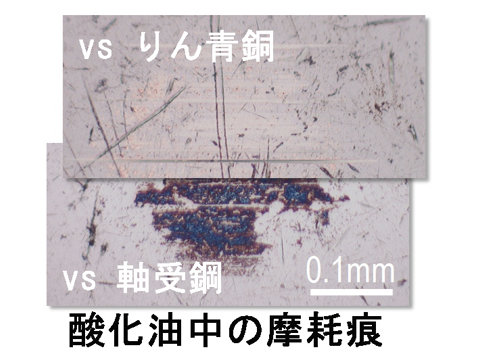

In order to prevent global warming, we are conducting research on lubricants (water, biomass alcohol, vegetable oil) that do not increase the concentration of carbon dioxide in the atmosphere. Sliding materials and lubrication films suitable for lubrication with water or alcohol have been developed. In order to lubricate with vegetable oil, we are also developing sliding materials with excellent fatty acid adsorption ability and corrosion resistance.

-

2.Functional Tribology

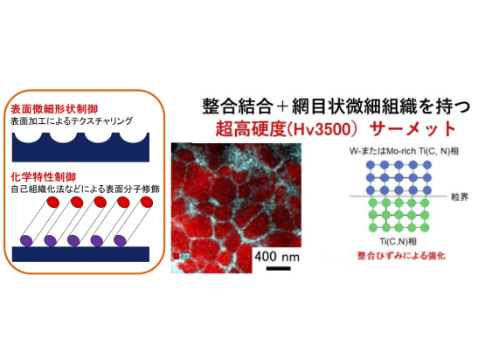

The "Surface" is deeply involved in friction, lubrication and wear. By adding functions to this surface, friction can be controlled appropriately. As a result, new functions such as improved performance, energy saving etc. can be achieved. For instance, we are developing highly functional surfaces for the purpose of controlling the chemical properties of the surface by applying fine shapes and molecular modifications to the surface, controlling the tribological properties, and controlling the wettability and adhesion properties to the surface. It is also important to develop more functional materials. We are thus developing Ti(C, N)-based cermets with excellent high-temperature strength suitable for cutting difficult-to-cut materials. Also we are developing high-temperature sliding borides with high melting points and ultra-high hardness.

-

3.Evaluation of Tribological Properties

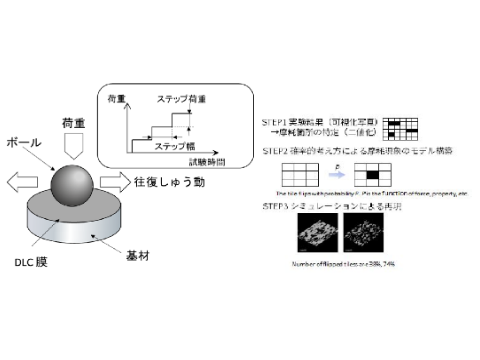

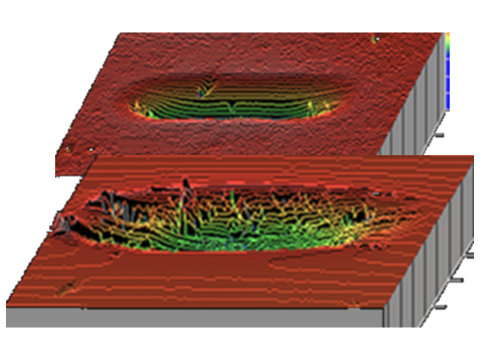

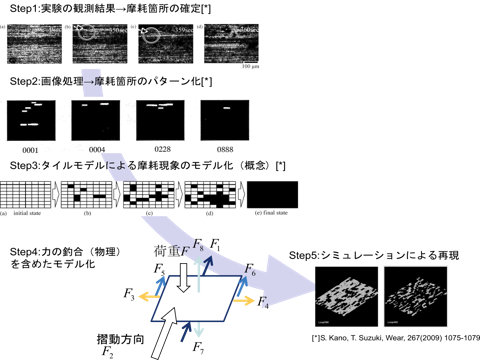

The knowledge on the evaluation of tribological properties is being applied to various applications. As an example, we have developed a load carrying capacity test method for DLC films using a reciprocating sliding test in which the load is increased step by step, and are working on its standardization. For the frictional wear, due to the phenomena is complex and difficult to formulate, the stochastic simulation models which is based on the observations are used to reproduce the actual trends of the phenomena.

Themes

-

Lubrication properties of vegetable oils for various tribological materials

Eco-tribologyLow environmental impactNatural fluids

The mechanisms affecting lubrication properties are being investigated for vegetable oils with low toxicity and superior biodegradability.

The mechanisms affecting lubrication properties are being investigated for vegetable oils with low toxicity and superior biodegradability.

-

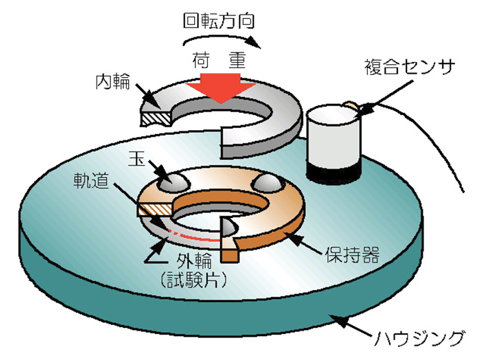

Diagnosis for rolling bearings

DiagnosisBearingsMaintenance tribologyAcoustic emission (AE)

Predictive diagnosis method on rolling contact fatigue failure is being developed for rolling bearings.

Predictive diagnosis method on rolling contact fatigue failure is being developed for rolling bearings.

-

Water Lubrication System, Alcohol Lubrication System

Environmentally Friendry TribologyLow Environmental Burden

View more

View more

-

Nanolubrication

Friction Control

We developed self-reparing nano structures and aim to improve the fitting capability and sliding characteristics.

We developed self-reparing nano structures and aim to improve the fitting capability and sliding characteristics.

-

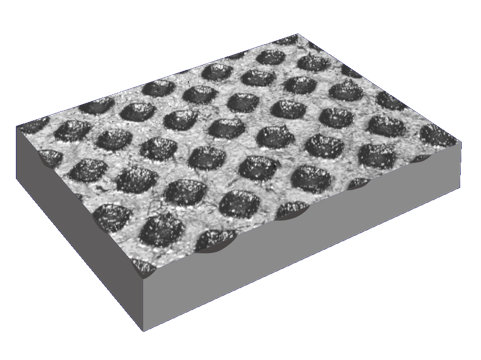

Functional Fluid Lubrication -Improvement of Parallel Plate Lubrication Characteristics by Surface Texturing-

Friction ControlSurface FunctionTexturing

We are carring out the reserch on clarifying the mechanism and applying it to actual equipment for technology that improves lubrication characteristics by processing fine unevenness on the sliding surface.

We are carring out the reserch on clarifying the mechanism and applying it to actual equipment for technology that improves lubrication characteristics by processing fine unevenness on the sliding surface.

-

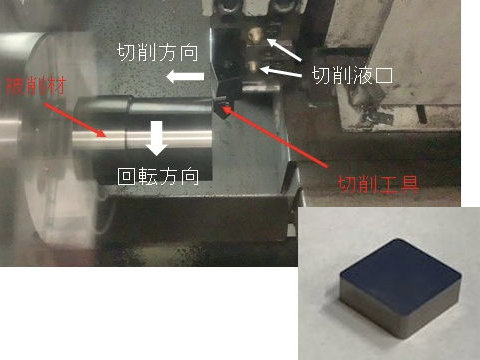

Developments of new cermet with high strength and oxidation resistance at high temperatures, and new high-temperature sliding materials.

Tool MaterialsCermetHigh-Temperature HardnessCuttingSpark Plasma SinteringTi(C, N)Borides

Developments of Ti(C, N)-W cermets with higher hardness and oxidation resistance than conventional cemented carbides and cermets at high temperatures.

Developments of Ti(C, N)-W cermets with higher hardness and oxidation resistance than conventional cemented carbides and cermets at high temperatures.

Press release : Sep. 14, 2020 View more -

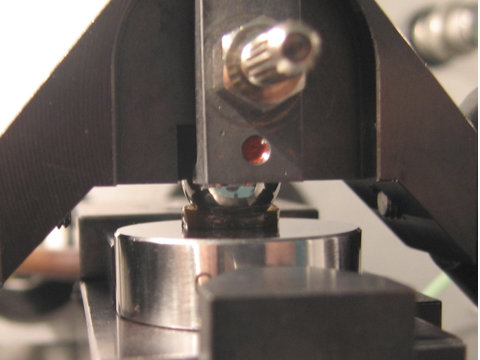

Development of evaluation method for load carrying capacity of DLC films

Evaluation of tribological propertiesStandardizationDLC filmsLoad carrying capacityAnti-adhesion characteristicsFriction and wear test

An evaluation method for the load carrying capacity of DLC films has been developed, with the aim of proposing it as an international standard.

View more

An evaluation method for the load carrying capacity of DLC films has been developed, with the aim of proposing it as an international standard.

View more

-

Evaluation of tribological properties using SRV tribotester

Evaluation of tribological propertiesFriction and wear characteristicsDatabase

Various friction and wear testers such as SRV tribotester are used to evaluate tribological properties under wide range conditions.

Various friction and wear testers such as SRV tribotester are used to evaluate tribological properties under wide range conditions.

-

Simulation of frictional wear

Friction/WearDesign

For the frictional wear which are complex and difficult phenomenena to formulate, we simulate using stochastic models.

For the frictional wear which are complex and difficult phenomenena to formulate, we simulate using stochastic models.

-

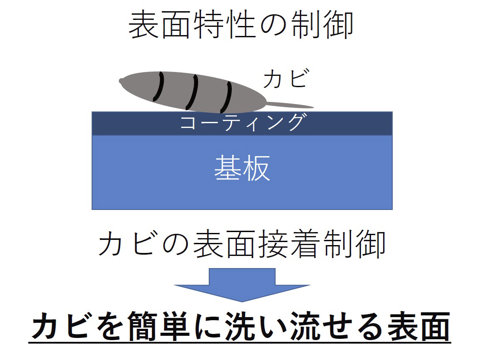

Development of antifungal technology by control of the surface properties

FungiAdhesionSurface Modification

We have developed a coating technology that controls the chemical properties of the surface to suppress the adhesion of fungi to the surface and to easily remove fungi growing on metals, ceramics, and glass by washing with water.

We have developed a coating technology that controls the chemical properties of the surface to suppress the adhesion of fungi to the surface and to easily remove fungi growing on metals, ceramics, and glass by washing with water.