Equipments

Tribometers

Tribometers chracterize friction and wear.

Tribometers have several methods. It is necessary to select the most suitable method depending on the object to be examined.

-

Thrust Cylinder Type Tribometer EFM-3

- With one-way rotation, face-to-face contact test and point contact test can be performed by thrust cylinder type and pin-on-disk type, respectively.

- Dry conditions and lubrication conditions by oil bath can be tested.

- It is suitable for the evaluation of plain bearing materials.

-

Bloch-on-Ring Tribometer LFW-I

- Line contact test and face-to-face contact test can be perfomed under dry conditions and lubrication conditions with oil bath by block-on-ring type and with one-way rotation.It is suitable for the evaluation of engine oil, transmission oil, etc..

-

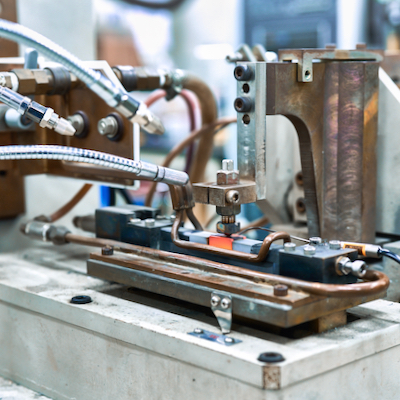

Fretting Tribometer SRV 3

- With reciprocating motion, point contact test and line contact test can be performed by ball-on-plate type and cylinder-on-plate type, repectively.

- Dry conditions and lubrication conditions by minimal amout and with oil bath can be tested.

- Coefficient of friction can be measured while changing load and oscillation speed under computer control.

- It is suitable for the evaluation of lubrication characteristics and seizure resistance of oil and grease.

-

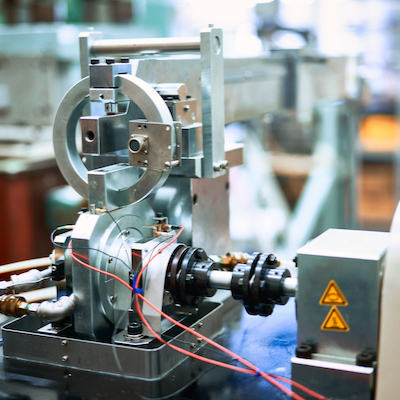

High-Speed Reciprocating Friction Tester

- This tester is used to evaluate piston rings and cylinder liners, and is possible to experiment with dry conditions, minimal quantity lubricationa (application), and lubrication conditions by continuous dripping using a pump.

-

High-Temperature Friction Tester

- You can perform reciprocating pin-on-plate friction tests of metal, ceramic and resin specimens at high temperatures because metal-based specimen holder can be heated by high frequency induction heating.

-

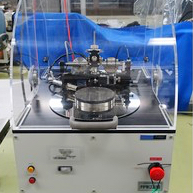

Light Load Friction Force Distribution Measuring Device

- Reciprocating friction measurement and friction distribution measurement can be performed using the pin-on-plate method with a light load (up to 98 mN).

- Tribometer can be performed for same-circle rotation, circular reciprocating sliding, and linear reciprocating sliding.

- It is capable of measuring in liquid and heating.

Bearing Tester

Equipment for fatigue testing and life testing for rolling bearings.

-

JSPS Type Ball Bearing Life Tester It is one of the standard bearing tester in Japan developed by the 126th Committee on Rolling Bearing Life in the Japan Society for the Promotion of Science (currently active as Technical Committee on Life of Rolling Bearings in the Japanese Society of Tribologists). A life test (fatigue test) is performed by applying a constant load to the test radial bearing and rotating it at a constant speed. The life distribution data and other research results obtained by this bearing tester are widely disclosed to the general public through reports, papers, and explanatory articles.

-

Multiple Radial Rolling Bearing Life Tester A life test (fatigue test) is performed by applying a constant load to multiple test radial bearings and rotating them at a constant speed. It is suitable as a platform for research for diagnosis because it targets versatile radial bearings.

-

Thrust Ball Bearing Life Tester A life test (fatigue test) is performed by applying a load to the test bearing (thrust bearing) and rotating it at a constant speed. Due to the structure of thrust bearings, all rolling elements are operated under a constant load. Therefore, It is suited to reliability assessment for bearing washer materials and rolling element materials because it is sensitive to the number of stress repetitions.

Evaluation/Sample Preparation Equipment

Equipments for measuring and evaluating characteristics of the surfaces before/after friction and wear, and surface conditions/Sample preparation equipment.

-

Non-Contact Profilometer

(Zygo NewView 5000)- This is a non-contact surface profilometer using scanning white light interferometry.

- Wear scar, surface roughness and cross-sectional profiles can be easily observed and measured.

-

Scanning Electron Microscope

(JSM-7400F)- You can take secondary electron and compositional images. Also you can perform surface, point and line elemental analysis including light elements.

- You can observe 25 to 650,000 times at the accelerating voltage of 0.1 kV to 30 kV using this microscope.

-

Scanning Electron Microscope

(JSM-6060)- It is equipped with a large chamber for observing large samples.

- An EDS is also available for qualitative and quantitative analysis of various elements.

-

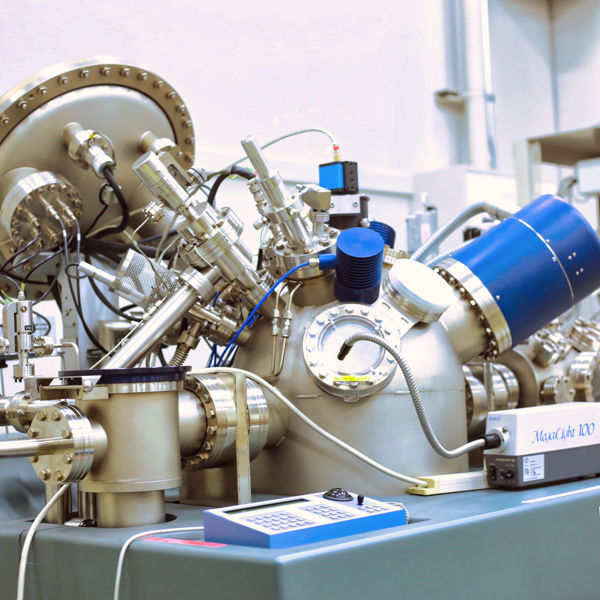

X-ray Photoelectron Spectroscopy

(ThetaProbe)- The constituent elements of the sample surface and their chemical states can be analyzed.

- Simultaneous angle-resolved XPS spectra can be acquired.

- A chamber with an atmosphere-controlled friction units allows surface analysis before and after friction testing without the effects of air pollution.

-

Spark Plasma Sintering Machine

- Its maximum sintering temperature is 2400 degree C. You can obtain dense and porous resin, metal, ceramic and composite samples using this machine.