Theme

Developments of new cermet with high strength and oxidation resistance at high temperatures, and new high-temperature sliding materials.

- Appearance of our developed cermet cutting tool.

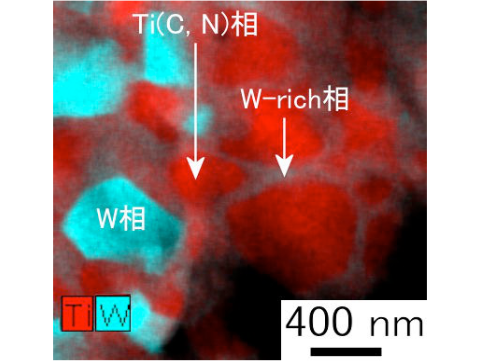

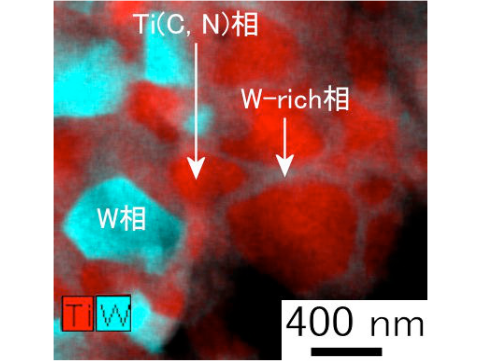

- TEM-EDS image of our developed cermet specimen.

- 開発サーメット製焼結型の外観

Research Keywords

Tool material, cermet, high-temperature hardness, cutting, spark plasma sintering, Ti(C, N), borides

Research Objectives

The use of difficult-to-cut materials such as Inconel 718 alloy and super-stainless steel has been increasing in the fields of aircrafts and thermal power turbines. When cutting these difficult-to-cut materials, the cutting tool edges rise to nearly 1000 degree C. Thus we have to develop new cutting tools with excellent high-temperature hardness and chemical stability. We are developing new tool materials suitable for cutting difficult-to-cut materials efficiently by strengthening ultra-hard particles with a high-melting-point metal binder to enhance high-temperature hardness and chemical stability compared to conventional tool materials. We are also developing new sliding materials suitable for forging molds and bearings used at temperatures around 1000 degree C.

Research results

-

Develop of new cermets with excellent high-temperature hardness and oxidation resistance Explanation of our research results

TEM-EDS image of our developed cermet.

TEM-EDS image of our developed cermet. -

Develop of low friction borides at high temperatures Explanation of our research rsults

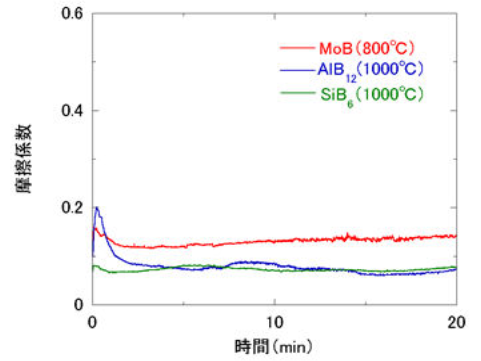

Friction coefficients of Al, Si Mo borides at high temperatures.

Friction coefficients of Al, Si Mo borides at high temperatures.

Links(external publications, patents, related news, etc.)

- T. Murakami, A. Korenaga, T. Ohana. Pressurized sintered body and its manufacturing method, Japanese Patent Application No. 2020-051224, application date: March 23, 2020.

- T. Murakami, A. Korenaga, T. Ohana. Microstructure, mechanical properties, oxidation behaviors, and cutting performance of TiC0.5N0.5-X (X: W, Mo) cermet specimens prepared by spark plasma sintering, Ceramics International, Vol. 47, No. 2 (2021) 1986-1999. https://doi.org/10.1016/j.ceramint.2020.09.030

- T. Murakami, A. Kornaga, T. Ohana, H. Inui. High-temperature tribological properties of Mo-Si-B intermetallic alloy/Si3N4 tribopairs, Intermetallics, Vol. 100 (2018) 151-162. https://doi.org/10.1016/j.intermet.2018.06.010

Contact

- Dr. Takashi Murakami, tribology group

- Email:murakami.t@aist.go.jp