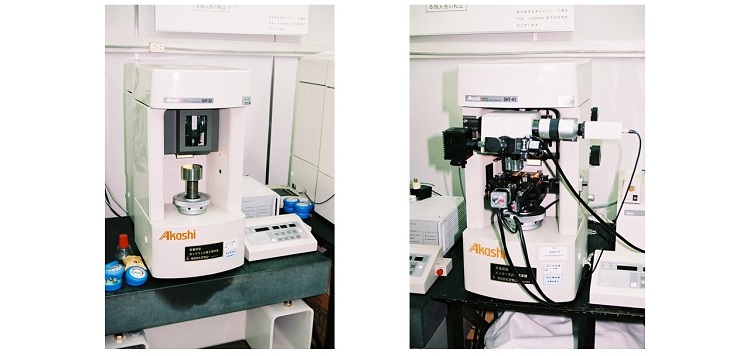

Primary Rockwell (left) and Vickers (right) hardness standards

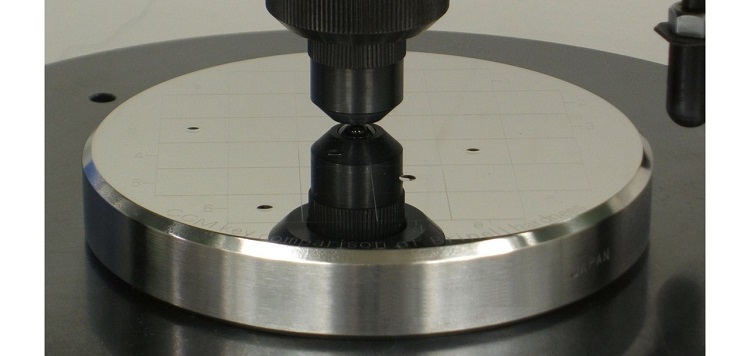

Brinell hardness test

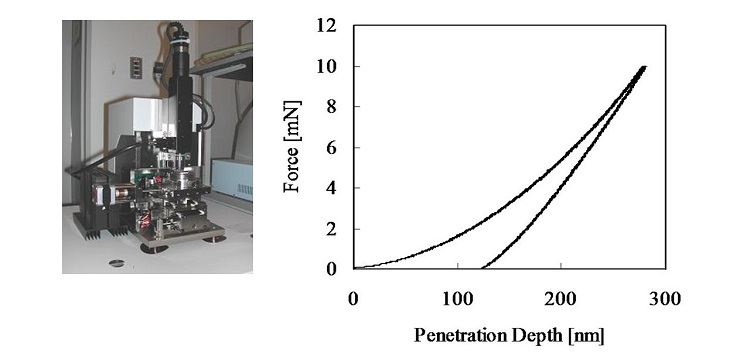

Nanoindentation instrument, and measurement example for fused silica

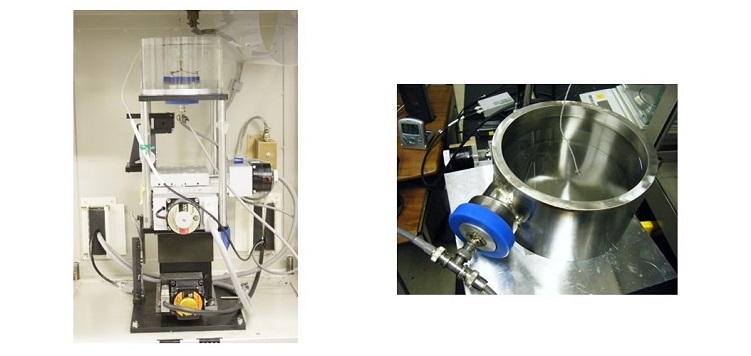

Ultrasonic power calibration system using radiation force balance (left), and calorimetric technique (right)

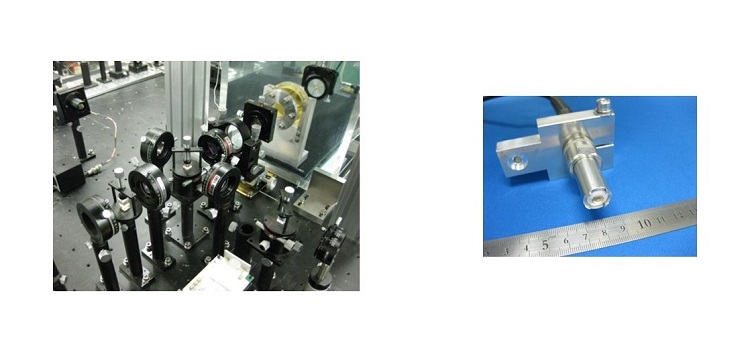

Hydrophone calibration system using laser interferometry, and ultrasonic transducer with small apaerture

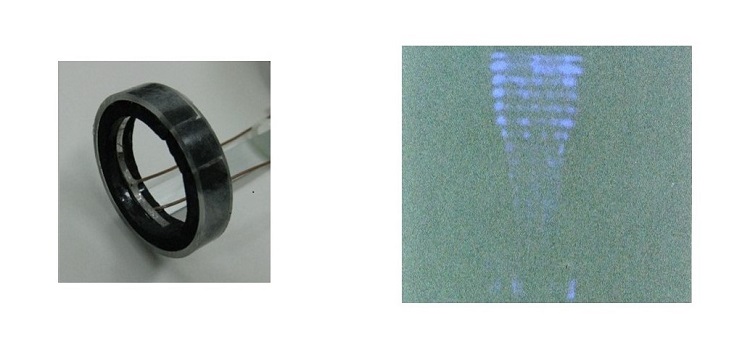

Cavitation sensor, and image of sonoluminescence

The group conducts R&D on measurement techniques for material strength and ultrasound, maintains and disseminates related measurement standards. Regarding material strength, we focus on the calibration techniques and uncertainty evaluation methods for hardness standard, and provide the measurement standards, mainly Rockwell hardness and Vickers hardness. Regarding ultrasound, we undertake research on ultrasonic field measurement that is useful for evaluating equipment using ultrasonic waves. We also provide standards such as for calibrations for hydrophone (underwater ultrasonic microphone) sensitivity for acoustic pressure measurement and ultrasonic power radiated from ultrasound sources.

Research Themes

- Research and development on instruments and testing methods to evaluate material strength to ensure the safety and reliability of mechanical products and structures.

- Research and development on precise measurements of ultrasonic field useful for performance and safety evaluation of ultrasonic medical equipment which radiates ultrasonic wave on human body.

- Research and development on quantitative measurement techniques of cavitation that affects ultrasonic cleaning capability and plumbing pipes.

Contact

Group leader

E-mail: <at> aist.go.jp