Innovative Laser Processing Group

Group Outline

Laser processing is expected to play a key role in next-generation manufacturing.

Our group is working on the development of advanced light sources such as Yb-doped

ultrashort pulse lasers with high-efficiency and high-power as well as material

processing based on unique laser-induced phenomena. Our goal is to contribute to society

by creating laser technology that makes the impossible possible.

Key Themes of Research

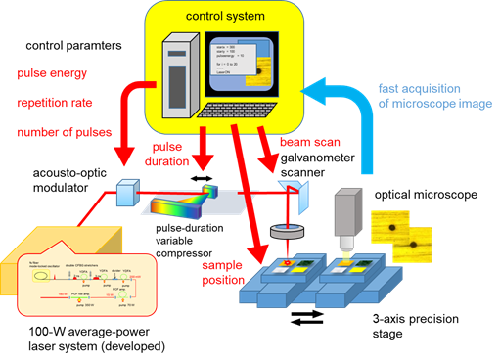

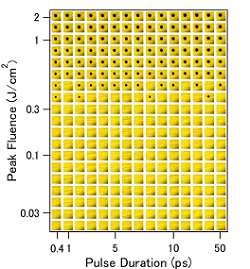

- We develop a new ultrashort pulse laser system that can change multiple process parameters in a wide range, such as pulse duration of 400 fs to 400 ps, which is useful for fast process optimization.

- We promote laser biomedical applications like future dental treatment and artificial joints. Joint research projects have been conducted with companies, universities and research institutions on laser precision microfabrication of hard-to-machine materials, laser-induced forward technology and so forth.

- Development of laser processing technology targeting brittle materials such as glass, hard-to-machine materials such as carbon fiber reinforced plastics (CFRP) and composite materials such as ceramic-based composite materials (CMC), and devices such as thin-film solar cells.

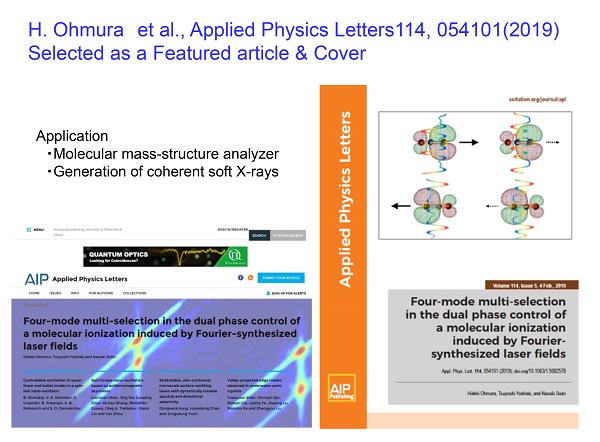

- As an application for the manipulation of matter by using intense waveform-tailored laser fields in the attosecond time region, we will explore cutting-edge measurement technology and laser processing that were difficult with conventional laser technologies.

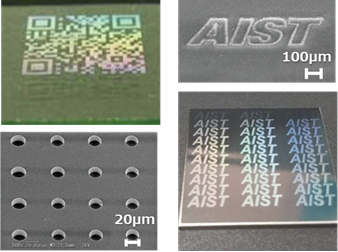

Laser precise microfabrication of various materials: laser marking on glass (top left), formation of through-holes in glass (bottom left), laser printing of conductive particles by laser-induced forward transfer (top right), and laser coloring of metal (bottom right)

Schematic diagram of the parameter-variable laser processing system for efficient optimization of process conditions. It takes as short as 30 minutes to obtain the microscope images of the ablation craters with several hundreds of parameter sets.

Applied research on material manipulation by strong laser fields

Our Technologies and Equipment

- Laser nano/micro processing of various materials including hard-to-machine materials like glass.

- Design and fabrication of ultrashort pulse lasers, control and evaluation technology for ultrashort pulses.

- Rapid inspection of surface material composition by LIBS (Laser-Induced Breakdown Spectroscopy) method.

- Delivery technology of nano/micro particles and biochips by LIFT (Laser-Induced Forward Transfer).