Lightweight Metallic Materials Research Group

We are developing technology to enhance the recyclability and formability of light metals, such as aluminum, magnesium, and titanium, aiming to reduce their life cycle environmental load and contribute to a circular society.

Group Research Theme

In-situ observation technique for aluminum solidification

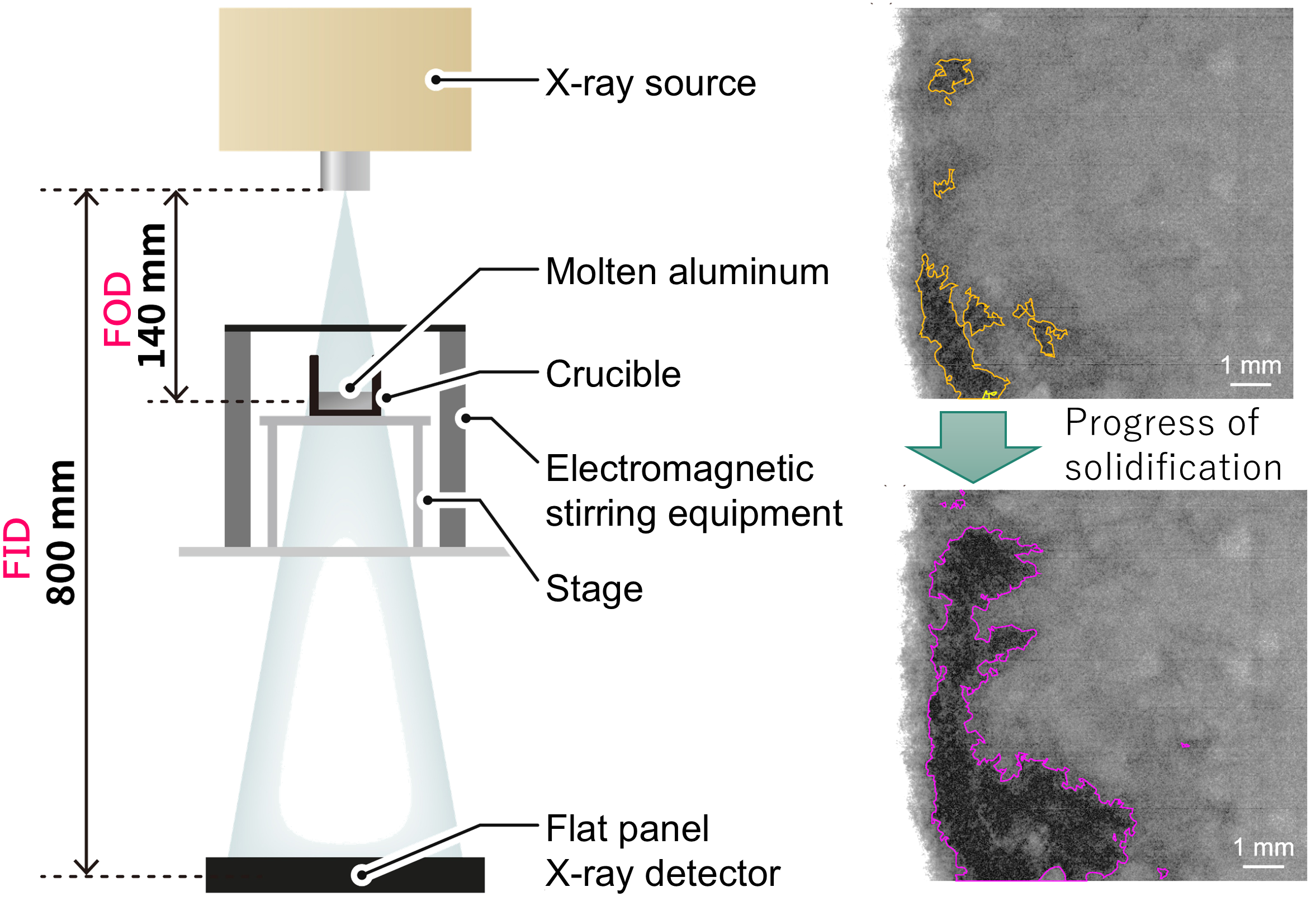

We are developing a next-generation recycling technology that combines fractional crystallization with electromagnetic stirring to enhance the recovery of high-quality metals. A key challenge in advancing recycling processes is understanding how molten metal solidifies under flow conditions, as this directly influences the final microstructure and material quality. To address this, we focus on visualizing the solidification behavior of molten metals during processing. Since metals are opaque to light, traditional optical methods are ineffective. While synchrotron radiation X-ray imaging has been used to observe metal solidification, its limited observation area—only a few tens of mm²—makes it unsuitable for studying solidification in the fractional crystallization process. To overcome this limitation, we have developed a novel X-ray imaging system capable of capturing the solidification process of flowing molten metal with both high resolution and a significantly larger field of view. By vertically aligning a microfocus X-ray source, an electromagnetic stirring device, and an X-ray detector (as shown in the left figure), our system enables real-time, two-dimensional visualization of alloy solidification under melt flow. This new technique offers an observation area more than 100 times larger than that of conventional methods (see right figure). We continue to refine and expand this in-situ imaging technology as a powerful tool for studying solidification dynamics—from grain growth to defect formation—across both micro and macro scales.

X-ray imaging system developed (left) and transmission X-ray images taken with the developed system (right)

Development of circulation technology for aluminum materials

Aluminum alloy is expected to help address global warming issues as a lightweight material, but its electrolytic smelting process generates a significant carbon footprint. Recycling aluminum can lower greenhouse gas emissions to less than 1/20 of those from new ingots. However, aluminum scrap contains various elements that become impurities in recycled aluminum, limiting its applications.

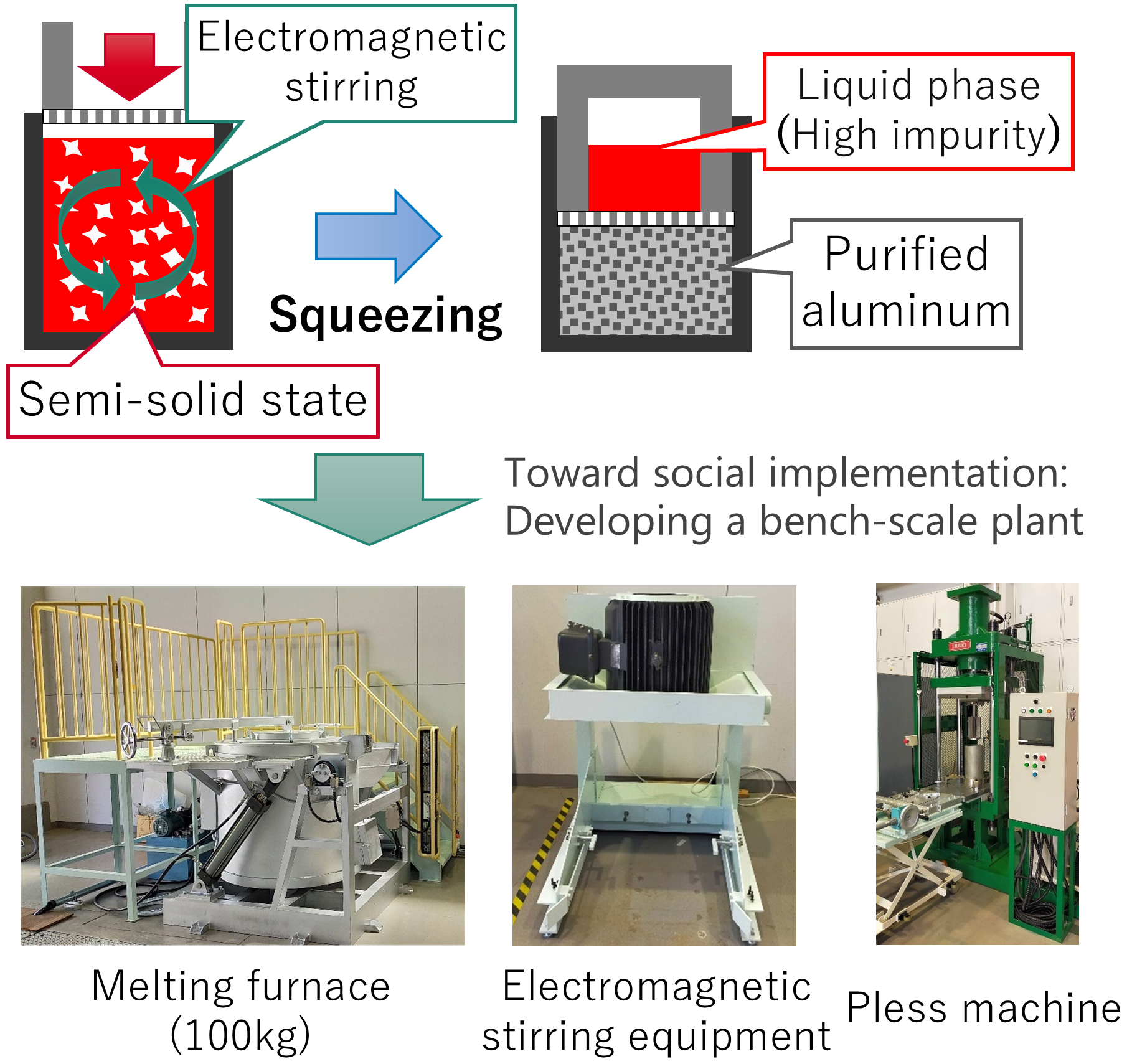

When molten aluminum scrap is cooled to a solid-liquid coexistence state, the solid phase becomes high purity, and most impurity elements are concentrated in the liquid phase. By using a filter in this situation, the solid phase and liquid phase can be separated, allowing for the extraction of high-purity solid aluminum. In previous technologies, the increasing impurity element concentration in aluminum scrap led to decreased yield, and this method could only be applied to high-quality aluminum scrap. To address this issue, we have developed a method to increase yield by applying electromagnetic stirring. We have now installed a bench-level plant and are identifying and addressing challenges related to scaling up.

Impurity Element Removal Technology by Fractionated Crystal Method and Bench Plant Construction for Social Implementation

Staff Members

| position | name | |

|---|---|---|

| Leader, Group | MURAKAMI Yuichiro | |

| Senior Researcher | SHIGA Keiji | |

| Senior Researcher | HUANG Xinsheng | |

| Senior Researcher | WATAZU Akira | |

| Senior Researcher | LI Mingjun | |

| Senior Researcher | HOSOKAWA Akihide | |

| Attached to Research Group | OMURA Naoki |

- Top page

- About Us

- Research Groups

- Materials Joining Research Group

- Lightweight Metallic Materials Research Group

- Ceramic Components and Processing Research Group

- Engineering Ceramic Research Group

- Wood-based Composites Research Group

- Next-Generation Electromaterials Research Group

- Advanced Metal Powder and Process Research Group

- Sensing Materials Research Group

- Carbon-Neutral Materials Research Group

- Functional Magnetic Materials Research Group

- Environmentally Adaptive Interface Materials Research Group

- Job Opportunities

- Access

- Contact