Biosurfactant Forum Japan

"We define biosurfactants (BSs) as surfactants produced by fermentation."

In recent years, from the perspective of environmental issues and economic development, biotechnology has received acknowledgment of its importance with increased expectations. The transition to bio-based products, clearly witnessed in the energy industry, is now being adopted worldwide in chemical products, including the surfactant industry.

The global market for bio-based surfactants, including surfactants produced by microorganisms (biosurfactants, BSs), is expected to expand from approximately 1.5 trillion yen in FY2021 to 2.4 trillion yen in FY2030. In particular, the BS market is expected to grow at a high rate as leading global companies have begun to enter the market seriously. (reference data: TPC Marketing Research Corp.)

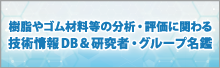

The history of BS research dates back to the 1950s, and although attempts have been made since then to develop production and utilization technologies for industrial use, it was not until around 2010 that BS was actually introduced to the market. Japanese companies were the first in the world to have applications for BSs. Even at present, several companies are developing businesses that take advantage of their unique characteristics.

The Research Institute for Sustainable Chemistry has disseminated many research results on developing BS production and utilization technologies. It has also successfully implemented BS in society through corporate collaborations. However, we believe that manufacturing technology and product variation are insufficient to raise awareness of BSs and make it popular. In addition, with the trend toward a circular economy, competition has been intensifying over the past few years with the entry of foreign companies. Therefore, we decided to establish a place where people from domestic companies, universities, and research institutes could gather to support the revitalization of domestic BS research. With the support of five domestic companies, we decided to launch the Biosurfactant Forum Japan. Future activities and basic information will be introduced on this page.

(Permission to publish materials has been granted by each company)

Information

【Prospectus on BS circle】

Activity

【1st meeting, Jan-10-2023, Keio University】

【2nd meeting, May-17-2023, Saraya Co., Ltd.】

【3rd meeting, Oct-25-2023, AIST Chugoku center】

【4th meeting, Mar-11-2024, AIST Tohoku center】

In recent years, from the perspective of environmental issues and economic development, biotechnology has received acknowledgment of its importance with increased expectations. The transition to bio-based products, clearly witnessed in the energy industry, is now being adopted worldwide in chemical products, including the surfactant industry.

The global market for bio-based surfactants, including surfactants produced by microorganisms (biosurfactants, BSs), is expected to expand from approximately 1.5 trillion yen in FY2021 to 2.4 trillion yen in FY2030. In particular, the BS market is expected to grow at a high rate as leading global companies have begun to enter the market seriously. (reference data: TPC Marketing Research Corp.)

The history of BS research dates back to the 1950s, and although attempts have been made since then to develop production and utilization technologies for industrial use, it was not until around 2010 that BS was actually introduced to the market. Japanese companies were the first in the world to have applications for BSs. Even at present, several companies are developing businesses that take advantage of their unique characteristics.

The Research Institute for Sustainable Chemistry has disseminated many research results on developing BS production and utilization technologies. It has also successfully implemented BS in society through corporate collaborations. However, we believe that manufacturing technology and product variation are insufficient to raise awareness of BSs and make it popular. In addition, with the trend toward a circular economy, competition has been intensifying over the past few years with the entry of foreign companies. Therefore, we decided to establish a place where people from domestic companies, universities, and research institutes could gather to support the revitalization of domestic BS research. With the support of five domestic companies, we decided to launch the Biosurfactant Forum Japan. Future activities and basic information will be introduced on this page.

(Permission to publish materials has been granted by each company)

Information

【Prospectus on BS circle】

Activity

【1st meeting, Jan-10-2023, Keio University】

【2nd meeting, May-17-2023, Saraya Co., Ltd.】

【3rd meeting, Oct-25-2023, AIST Chugoku center】

【4th meeting, Mar-11-2024, AIST Tohoku center】

ABOUT BIOSURFACTANTS

Biosurfactants (BSs) are fermented products by microorganisms such as bacteria

and yeast strains. Their production yield is one of the highest (up to

several hundred g/L) among substances produced by the fermentation technology.

They are excellent surfactants that exhibit high functionality even at

low concentrations (surface activity is exhibited in a small amount). Therefore,

against the backdrop of growing awareness of environmental issues, research

has been underway since the 1960s to commercialize BS as an environmentally

friendly surfactant with high biodegradability and safety.

Additionally, while BSs are being studied as excellent surfactants, they are also being researched and developed as highly functional bio-based materials that take advantage of their diverse and unique functions arising from the characteristics of their molecular structures. For example, BSs are known to have functions not found in conventional surfactants, such as high self-assembling ability, anti-tumor activity, and biofilm suppression.

In the current major trend toward a circular economy, BSs are attracting attention as industries are promoting the use of bio-based chemicals. In terms of bio-transition of surfactants, they can be broadly divided into two types, including natural-based synthetic surfactants (bio-based surfactants) and BSs, which both are expected to expand in market size as environmentally friendly surfactants from the sustainability perspective.

According to their chemical structure, BSs are classified into three main types, which are (1) glycolipid type, (2) lipopeptide type, and (3) fatty acid type. All of them are complex and bulky due to the presence of multiple functional groups and chiral carbon atoms. Despite their extremely complex structures, they have uniform molecular structures with high regioselectivity and stereoselectivity. The bulkiness and uniformity of the molecular structure of BSs are thought to allow efficient molecular orientation at the interface, resulting in excellent surface activity even at very low concentrations.

(1) Glucolipid-type BSs

Sophorolipid (SL), Mannosylerythritol lipid (MEL), Rhamnolipid (RL), Trehalose lipid (TL), Cellobiose lipid (CL), Liamocin (LM)

(2) Lipopeptide-type BSs

Surfactin (SF), Arthrofactin, Iturin, etc.

(3) Fatty acid-type BSs

Spiculisporic acid (SA)

Additionally, while BSs are being studied as excellent surfactants, they are also being researched and developed as highly functional bio-based materials that take advantage of their diverse and unique functions arising from the characteristics of their molecular structures. For example, BSs are known to have functions not found in conventional surfactants, such as high self-assembling ability, anti-tumor activity, and biofilm suppression.

In the current major trend toward a circular economy, BSs are attracting attention as industries are promoting the use of bio-based chemicals. In terms of bio-transition of surfactants, they can be broadly divided into two types, including natural-based synthetic surfactants (bio-based surfactants) and BSs, which both are expected to expand in market size as environmentally friendly surfactants from the sustainability perspective.

According to their chemical structure, BSs are classified into three main types, which are (1) glycolipid type, (2) lipopeptide type, and (3) fatty acid type. All of them are complex and bulky due to the presence of multiple functional groups and chiral carbon atoms. Despite their extremely complex structures, they have uniform molecular structures with high regioselectivity and stereoselectivity. The bulkiness and uniformity of the molecular structure of BSs are thought to allow efficient molecular orientation at the interface, resulting in excellent surface activity even at very low concentrations.

(1) Glucolipid-type BSs

Sophorolipid (SL), Mannosylerythritol lipid (MEL), Rhamnolipid (RL), Trehalose lipid (TL), Cellobiose lipid (CL), Liamocin (LM)

(2) Lipopeptide-type BSs

Surfactin (SF), Arthrofactin, Iturin, etc.

(3) Fatty acid-type BSs

Spiculisporic acid (SA)

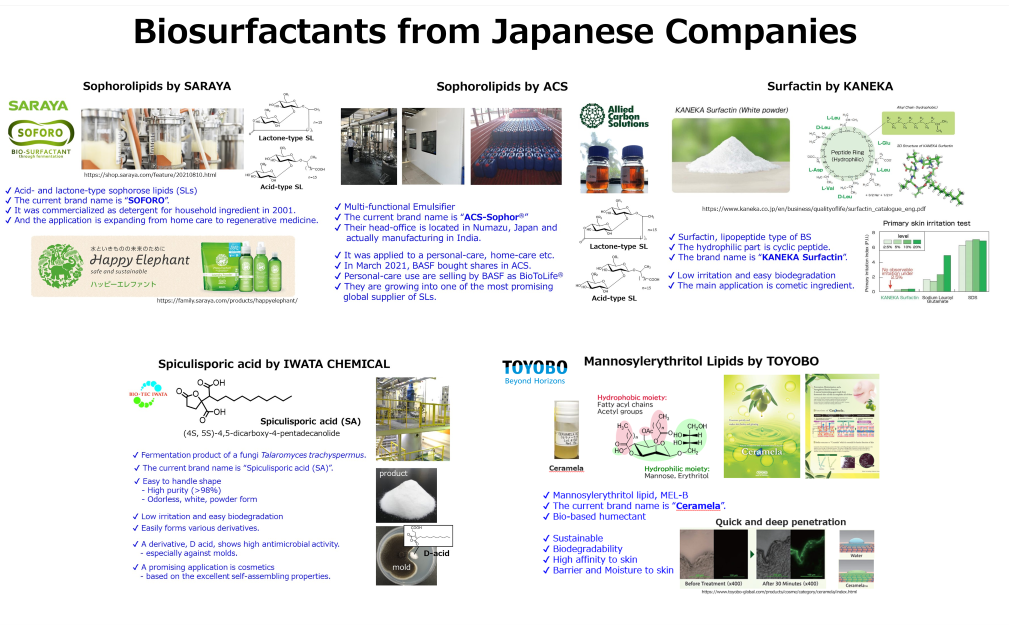

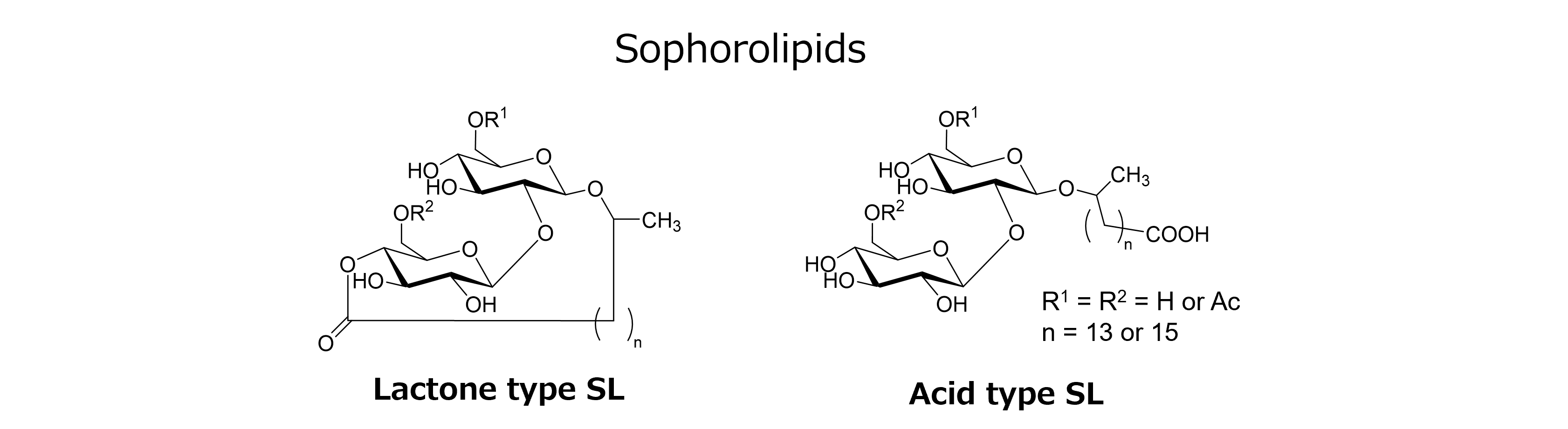

Sophorolipids(SLs)

Sophorolipids (SLs) are glycolipids composed of fatty acids with carbon

chain lengths of 16-18 bound to sophoroses and is usually produced in two

chemical forms: lactone-type SL and acid-type SL. The ratio of lactone-type

SL to acid-type SL varies depending on the microorganism producing it.

Other known forms of SL include bola-form SL, in which a second molecule

of sophorose is ester-bonded to the end of the fatty acid chain, and branched-form

SL, in which the hydroxyl group of the hydroxy fatty acid is bonded to

the sophorose.

Starmerella bombicola(formerly known as Candida bombicola) is a typical SL-producing yeast that can produce 300-400 g/L of SL from sugars and fats and accumulate it in the culture medium. Other known SL-producing yeasts include Starmerella floricola (formerly Candida floricola) and Pseudohyphozyma bogoriensis (formerly Rhodotorula bogoriensis).

Starmerella bombicola(formerly known as Candida bombicola) is a typical SL-producing yeast that can produce 300-400 g/L of SL from sugars and fats and accumulate it in the culture medium. Other known SL-producing yeasts include Starmerella floricola (formerly Candida floricola) and Pseudohyphozyma bogoriensis (formerly Rhodotorula bogoriensis).

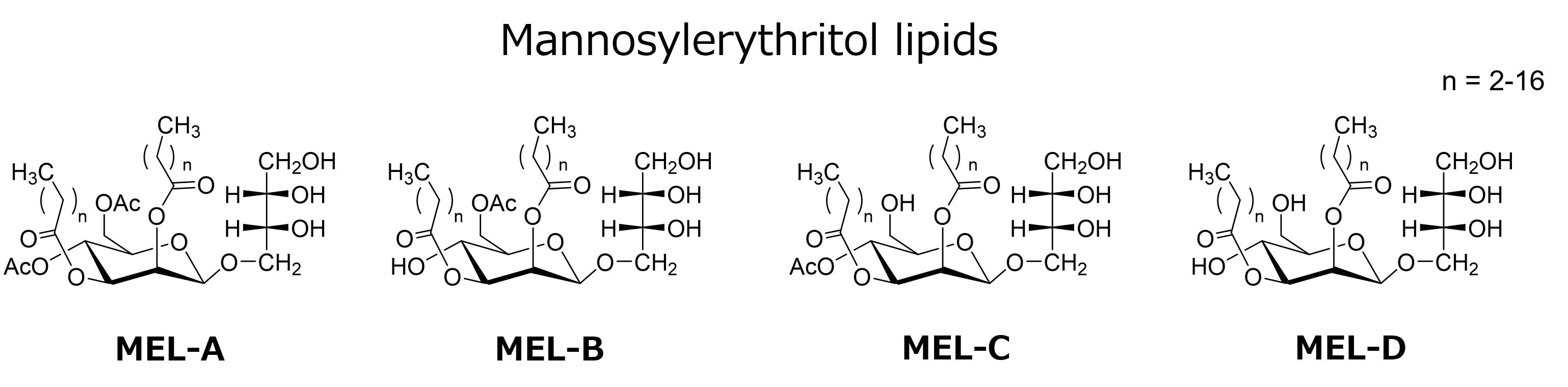

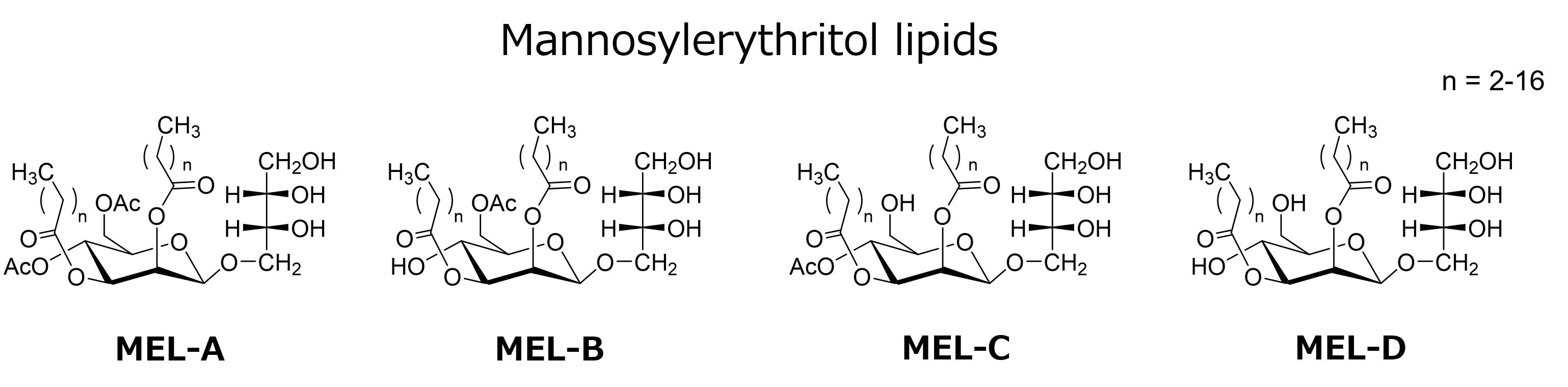

Mannosylerythritol lipids(MEL)

Mannnosylerythritol lipids (MELs) are glycolipids in which fatty acids with a carbon chain length of 4-18 and acetyl groups are bonded to mannosylerythritol (ME), which is a combination of mannose and erythritol. The main structure is a double-chain MEL consisting of short-chain (C4-8) fatty acid and medium-chain (C8-18) fatty acid attached to the mannose part of the supar part, mannosyl-erythritol. Based on the number and position of the acetyl groups, MEL can be divided into several analogs (e.g., MEL-A, MEL-B, MEL-C, and MEL-D). By modifying the medium composition and culture conditions, it is possible to produce triple-chain MEL with one additional fatty acid chain attached or single-chain MEL with only one fatty acid chain attached.

MEL is primarily produced by basidiomycete yeasts such as Moesziomyces antarcticus (formerly Pseudozyma antarctica) and Moesziomyces aphidis (formerly Pseudozyma aphidis, Pseudozyma tsukubaensis, Pseudozyma hubeiensis, etc.). MEL production can reach more than 100 g/L with vegetable oils as the carbon sources.

MEL is primarily produced by basidiomycete yeasts such as Moesziomyces antarcticus (formerly Pseudozyma antarctica) and Moesziomyces aphidis (formerly Pseudozyma aphidis, Pseudozyma tsukubaensis, Pseudozyma hubeiensis, etc.). MEL production can reach more than 100 g/L with vegetable oils as the carbon sources.

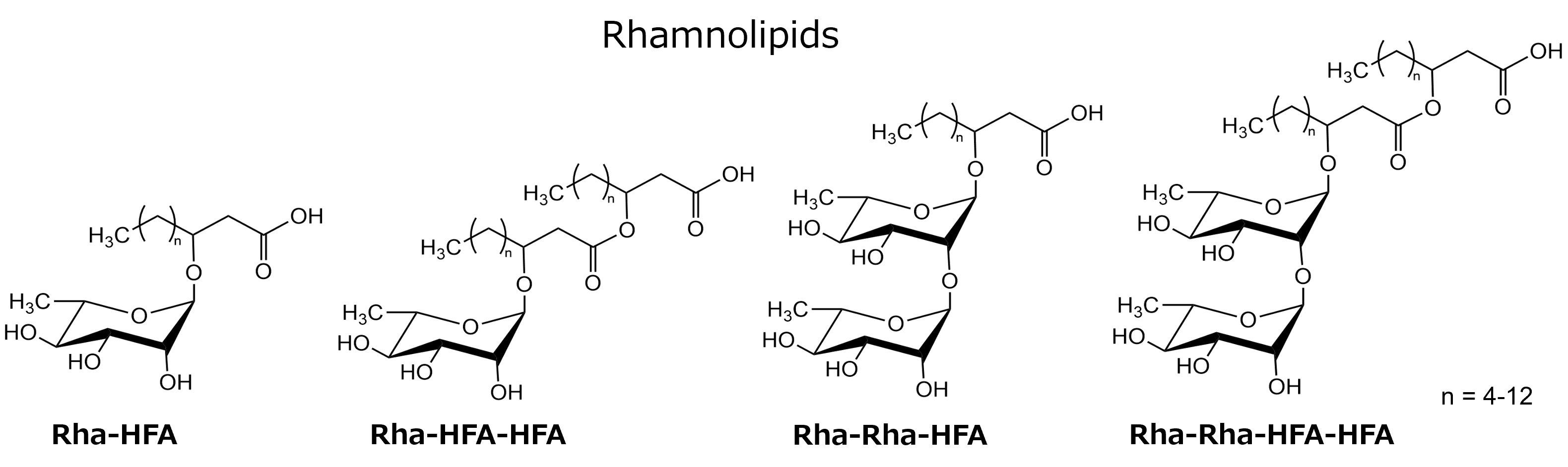

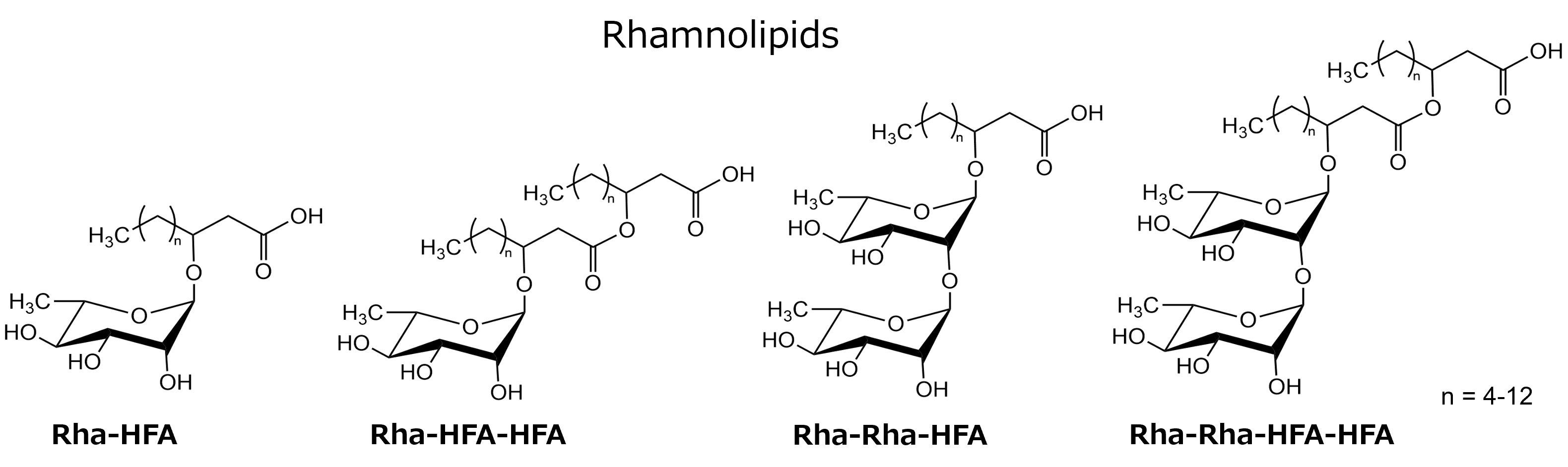

Rhamnolipids(RL)

Rhamnolipids (RLs) are glycolipids consisting of rhamnose bound to a β-hydroxy

fatty acid (HFA) with a carbon chain length of 8-16. There are four main

structures: monorhamnolipid (Rha-HFA or Rha-HFA-HFA), which consists of

one or two molecules of hydroxy fatty acid attached to one molecule of

rhamnose; di-rhamnolipid (Rha-Rha-HFA or Rha-Rha-HFA-HFA), which consists

of one or two molecules of hydroxy fatty acid attached to two molecules

of rhamnose.

The most famous RL-producing bacterium is Pseudomonas aeruginosa, which can produce more than 150 g/L by continuous culture, including the RL recovery process. On the other hand, since P. aeruginosa is an opportunistic infection organism, the development of non-pathogenic RL-producing bacteria is underway.

The most famous RL-producing bacterium is Pseudomonas aeruginosa, which can produce more than 150 g/L by continuous culture, including the RL recovery process. On the other hand, since P. aeruginosa is an opportunistic infection organism, the development of non-pathogenic RL-producing bacteria is underway.

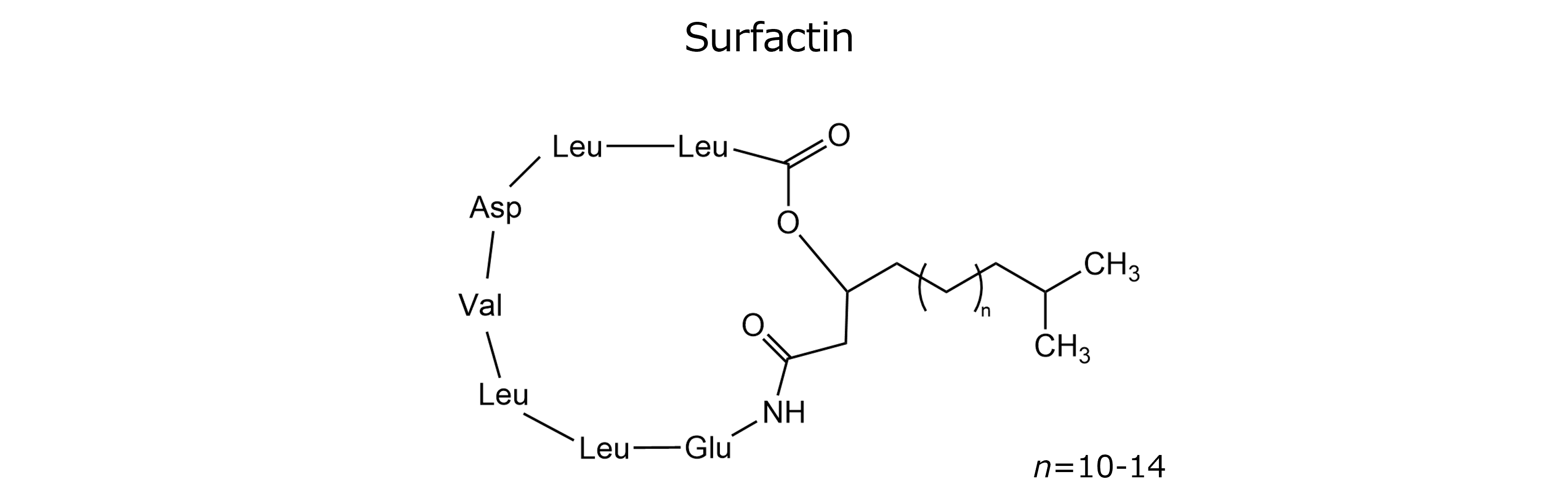

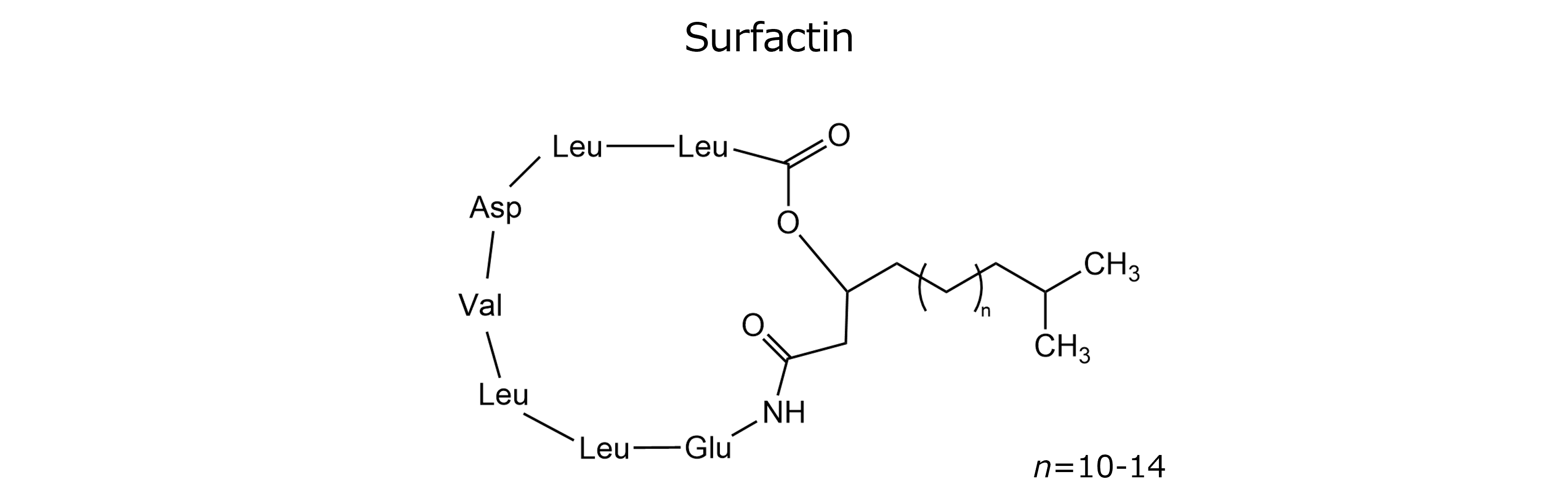

Surfactin(SF)

Surfactin (SF) is a lipopeptide-type BS consisting of a β-hydroxy fatty

acid chain with a carbon chain length of 12-16 attached to a cyclic peptide.

The cyclic peptide is composed of seven amino acids with "Glu-Leu-Leu-Val-Asp-Leu-Leu"

as a typical structure, but there are also known analogs in which the second

amino acid Leu is replaced by Ile, the fourth amino acid Val is replaced

by Ile or Ala, and the seventh amino acid Leu is replaced by Ile or Val.

SF is mainly produced by Bacillus subtilis, which can produce about 2 g/L SF with optimized medium composition and culture conditions. The development of SF-producing bacteria using genetic recombination technology is also progressing, with reports of success in SF production above 10 g/L.

SF is mainly produced by Bacillus subtilis, which can produce about 2 g/L SF with optimized medium composition and culture conditions. The development of SF-producing bacteria using genetic recombination technology is also progressing, with reports of success in SF production above 10 g/L.

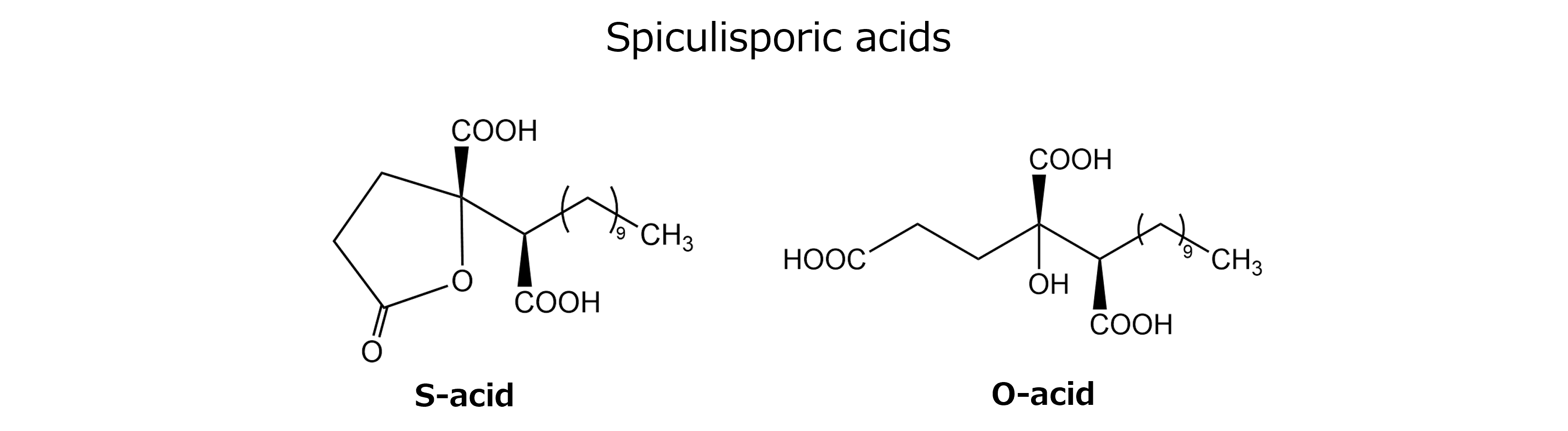

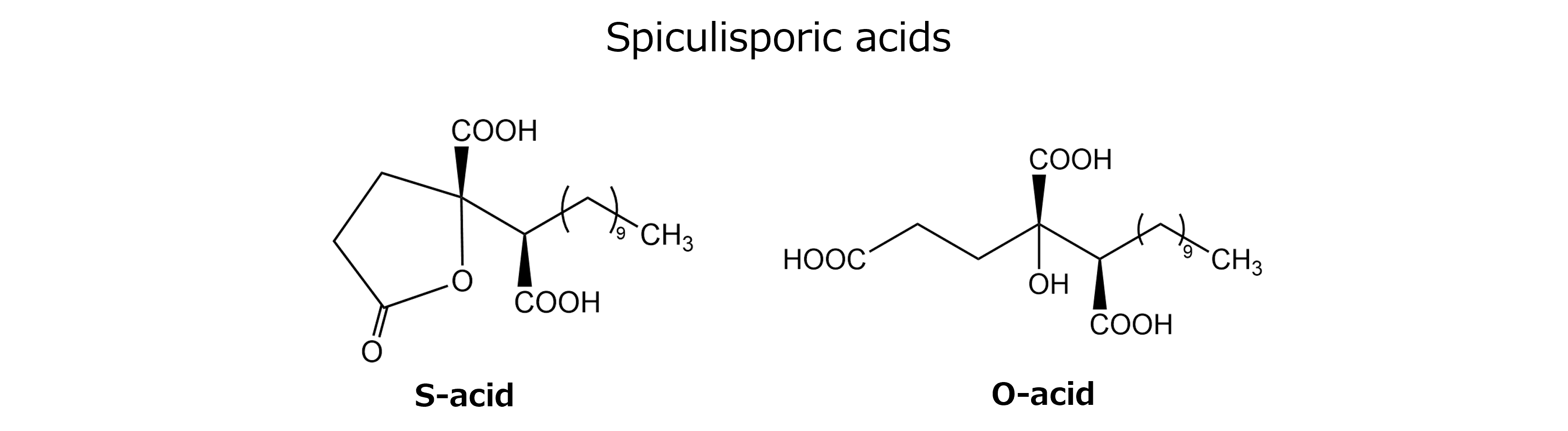

Spiculisporic acids(SA)

SA (4,5-dicarboxy-4-pentadecanolide), a fatty acid-type BS, is classified

into two forms, including lactone-form SA (S-acid, generally called SA)

and ring-opened-form SA (O-acid). O-acid is produced by microorganisms

and exists as needle-like crystals in the culture medium. On the other

hand, S-acid can be obtained by heat treatment of O-acid.

The main producer is Talaromyces spiculisporum (formerly known as Penicillium spiculisporum), a fungus belonging to the Ascomycetes family. The production yield of O-acid is more than 110 g/L in a fed-batch culture using glucose as the carbon source, in which glucose crystals are added to the medium.

The main producer is Talaromyces spiculisporum (formerly known as Penicillium spiculisporum), a fungus belonging to the Ascomycetes family. The production yield of O-acid is more than 110 g/L in a fed-batch culture using glucose as the carbon source, in which glucose crystals are added to the medium.

APPLICATION OF BIOSURFACTANTS

BSs are surfactants produced by microorganisms and have attracted attention from the perspective of environmental conservation. Since the 1960s, BSs have been studied as surfactants with high safety, biodegradability, and low environmental impact. Entering the 2000s, BSs have been studied as next-generation bio-based materials with advanced functions, as their physiological functions and unique molecular assembly properties, which are not found in conventional surfactants, were discovered by the life science approach.

In recent years, as initiatives such as SDGs (Sustainable Development Goals) and ESG (Environmental, Social, and Corporate Governance) have progressed and as we are entering an era in which sustainability, including raw materials, is required, the expectations for BSs are increasing higher than ever. According to the market forecast (sales) for BSs by application, detergents (36.4% of the total) and personal care (27.3%) are currently the mainstream, followed by food processing (9.1%) and agriculture (6.1%) (reference data: TPC Marketing Research Corp.).

On the other hand, as the characteristics of the molecular structure and functionality of BSs differ from those of their synthetic counterparts, it seems that more research is needed to fully utilize them. There are many reports on the functionality of each type of BS, but keywords such as environmental purification, biofilm, livestock feed, biopesticide, and antibacterial/antioxidant are expected to be applied and developed in a variety of industrial fields.

In recent years, as initiatives such as SDGs (Sustainable Development Goals) and ESG (Environmental, Social, and Corporate Governance) have progressed and as we are entering an era in which sustainability, including raw materials, is required, the expectations for BSs are increasing higher than ever. According to the market forecast (sales) for BSs by application, detergents (36.4% of the total) and personal care (27.3%) are currently the mainstream, followed by food processing (9.1%) and agriculture (6.1%) (reference data: TPC Marketing Research Corp.).

On the other hand, as the characteristics of the molecular structure and functionality of BSs differ from those of their synthetic counterparts, it seems that more research is needed to fully utilize them. There are many reports on the functionality of each type of BS, but keywords such as environmental purification, biofilm, livestock feed, biopesticide, and antibacterial/antioxidant are expected to be applied and developed in a variety of industrial fields.

BS MARKET

The global market for surfactants (in FY2021) is estimated to be approximately 4,447 billion yen on a sales basis (reference data: TPC Marketing Research Corp.). The breakdown is approximately 2.93 trillion yen for petroleum-based synthetic surfactants, 1.3 trillion yen for bio-based surfactants, and 33 billion yen for BS, with BSs accounting for approximately 0.7% of the total in FY2021. In the future, bio-based surfactants and BSs will grow against the backdrop of the global trend toward bio-based products. The global market in FY2030 is expected to be approximately 2.9 trillion yen for petroleum-based synthetic surfactants, 2.32 trillion yen for bio-based surfactants, and approximately 100 billion yen for BSs. In other words, the BS market size in FY2030 will increase approximately threefold compared to FY2021, and it will account for approximately 5.3% of the total market.

In addition, while petroleum-based synthetic surfactants tend to remain flat or slightly decrease, bio-based surfactants show significant growth and presence, which means that by 2030, petroleum-based and bio-based surfactants may be almost equal. Regarding the BS market, the growth rate is high (approximately 13% per year), despite the small number of products and small scale. The number of cases adopted from the perspective of sustainability and global environmental conservation is believed to increase, and BS is expected to grow as a next-generation surfactant. At present, a major challenge for market expansion is the establishment of a large-scale production system. However, with Evonik's plant in Slovakia expected to start full-scale operations around next year, companies in various countries are already moving to capture the future BS market.

In addition, while petroleum-based synthetic surfactants tend to remain flat or slightly decrease, bio-based surfactants show significant growth and presence, which means that by 2030, petroleum-based and bio-based surfactants may be almost equal. Regarding the BS market, the growth rate is high (approximately 13% per year), despite the small number of products and small scale. The number of cases adopted from the perspective of sustainability and global environmental conservation is believed to increase, and BS is expected to grow as a next-generation surfactant. At present, a major challenge for market expansion is the establishment of a large-scale production system. However, with Evonik's plant in Slovakia expected to start full-scale operations around next year, companies in various countries are already moving to capture the future BS market.

Contact address

Tomotake Morita

E-mail: tomotake-morita*aist.go.jp (Please send a message after changing

"*" to "@".)