Chemical Reaction System Design Group

For the purpose of contributing to the achievement of carbon neutrality in the materials and chemical industries, we are engaged in the research and development for designing reaction systems that realize energy-efficient chemical processes and synthesis technologies to produce functional materials without using fossil resources.

Main Research Subjects

1. CO2 separation technologies using ionic liquids and amine solutions

We have developed energy-efficient chemical absorbents composed of ionic liquids and amine solutions and the CO2-separation ionic liquid membrane superior to the conventional polymer membranes. Also, we are researching the energy-efficient CO2 capture process using these materials.

|

|

|---|---|

| (left) Apparatus for CO2 capacity measurement, (right) CO2-separation ionic liquid membrane |

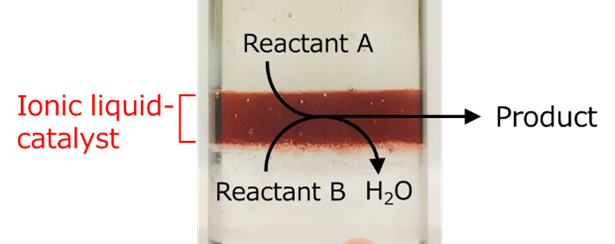

2. Ionic liquid catalysts for energy-efficient condensation reactions

We have established ionic liquid catalyst (ILC)-based technology that promotes various condensation reactions, in which reactants are dissolved in ILCs while water by-product is phase-separated from ILCs. These ILCs can effectively catalyze multiphasic condensation of immiscible reactants at <100 °C, whereas the conventional system required temperatures ~200 °C.

|

|

|---|---|

| Multiphasic condensation reactions using an ionic liquid catalyst (ILC) |

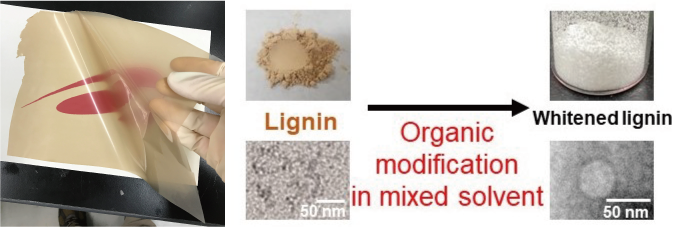

3. Development of functional Materials consisting of plant/mineral resources

We develop novel functional materials using lignin, a plant-originated aromatic polymer, and clay, a mineral-originated inorganic material. For example, the development of clay-lignin composite films for UV protection and the design of chemical reactions for whitening lignin have been performed.

|

|

|---|---|

| (left) UV protection film only from lignin and clay, (right) whitened lignin synthesized via organic modification |