![]() Structural health monitoring (SHM) is a key technology for daily life. Our group conducts research to develop new techniques and instruments for non-destructive testing. The main research topics are: 1) development of ultrasonic propagation imaging system and image processing technique for damage detection, 2) development of rapid and accurate deformation measurement system using fringe pattern by phase analysis technique and 3) characterization of physical properties at ultra-high temperatures of carbon materials.

Structural health monitoring (SHM) is a key technology for daily life. Our group conducts research to develop new techniques and instruments for non-destructive testing. The main research topics are: 1) development of ultrasonic propagation imaging system and image processing technique for damage detection, 2) development of rapid and accurate deformation measurement system using fringe pattern by phase analysis technique and 3) characterization of physical properties at ultra-high temperatures of carbon materials.

's Research Theme

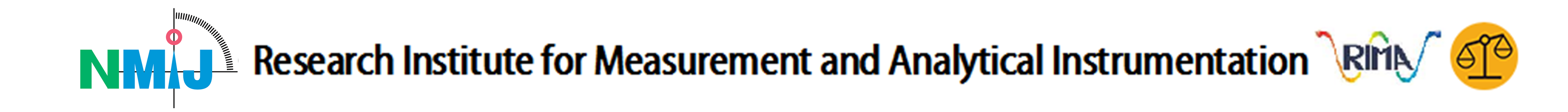

Fig.1: An image showing ultrasound propagation

of a metallic pipe having a defect on an inside wallDevelopment of SHM using ultrasound

◆Damage detection by ultrasonic propagation imaging

For damage detection of materials and structures, visualized ultrasound propagation data are more useful than waveform data. We are developing a contact-free nondestructive imaging system, which can easily visualize ultrasound wave propagation on the surface of an arbitrary shaped object, using thermal excitation of ultrasound by laser and its scanning. We are also developing image processing techniques to emphasize signals resulting from defects.

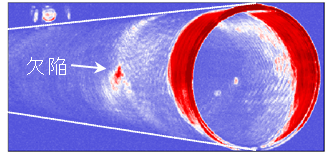

Fig.2:Measurement of small-displacement distribution

for large-scale structures by using advanced

image processing technique

Displacement measurement for large-scale structures utilizing image processing techniques

A simple and accurate full-field displacement measurement technique was developed for large-scale structures. The displacement distribution is determined from each single grating image before and after deformation. A sub-millimeter deflection in a 10-meter-long structure was successfully detected through this technique.

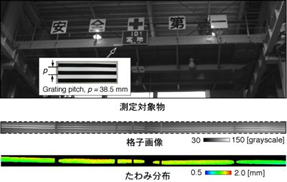

Characterization of physical properties of carbon materials

Techniques and instruments for measuring physical properties of carbon materials, such as artificial graphite electrodes and carbon fibers, under some ambiences suited for industrial application are developed. Our targets are the standardization of the characterization procedures and database construction.

Staff Members

| photo | name | field of expertise | |

|---|---|---|---|

|

Group Leader

TANAKA, Masahito (Conc.) |

Spectroscopy, polarimetry, physics chemistry, synchrotron radiation application, photo-chemistry, radiation physics | |

|

RI Shien (Conc.) | Optical method, Image measurement, Experimental mechanics | |

|

KOKUYAMA Wataru (Conc.) | High-frequency vibration standard, low-frequency vibration standard, angular velocity standard | |

|

NAGAI Hideki (Conc.) | Computational mechanics, Structural mechanics | |

|

NATSU Hou (Conc.) | 3D measurement, Digital holography, Phase imaging | |

|

YE Jiaxing (Conc.) | Machine learning, Signal processing, Intelligent system development for NDT applications | |

|

TANAKA Takumi (Conc.) | Image analysis, Radiation measurement, High-frequency circuit design |

※Please change "[at]" to "@"