Next-generation Permanent Magnet Materials Group

We are developing post-neodymium magnets such as samarium alloy and metastable alloy in order to overcome the resource problem and low heat resistance of neodymium magnets, which are the key to EV motors. In particular, because the performance of magnets is significantly affected by microstructures, we focus on the creation of new powder metallurgy processes.

Group Research Theme

Low oxygen powder metallurgy process

Rare earth magnets that are sensitive to oxidation can be prepared by powder metallurgy process under extremely low oxygen conditions without exposure to the atmosphere.

Sm-Fe-N sintered magne

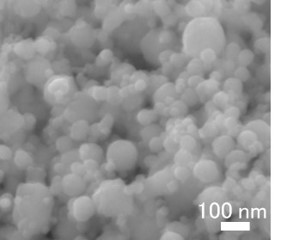

Rare earth magnet nanoparticles

Our developed thermal plasma technology is able to synthesize rare earth alloy nanoparticles, which has been difficult in the past. A sintered magnet with a coercive force of over 5T was realized from these nanoparticles.

Sm alloy nanoparticle

Staff Members

| photo | position & name | field of expertise | and other info |

|---|---|---|---|

|

Leader, Group,

Yusuke Hirayama |

electric and magnetic properties ; Metastable states ; Creation of nanomaterials ; Magnetic materials | |

|

Invited Senior Researcher,

Satoshi Sugimoto |

permanent magnet;soft magnetic material;microwave absorber | |

|

Senior Researcher,

Wataru Yamaguchi |

Permanent magnet ; Metal ; Powder Metallurgy ; grain boundary property ; Nanoparticle | |

|

Senior Researcher,

Akihide Hosokawa |

Processing and molding ; Thermomechanical treatments ; Microstructure control ; Powder Metallurgy | |

|

Senior Researcher,

Mingjun Li |

Melting and solidification ; Casting ; Electromagnetic processing ; Control of crystal structures ; Aluminum alloys ; Magnetic materials | |

|

Senior Researcher,

Jungryang Kim |

agnetic materials ; Permanent magnets ; rare-earth compounds | |

|

Senior Researcher,

Jian WANG |

Magnetic nanopowder ; Rare-earth-free magnet ; Microstructure analysis | |

|

Researcher,

Kwangjae Park |

Powder metallurgy ; Composite materials ; Permanent magnets ; Metal nanopowder |