Research Groups

Electroceramics Group

Leader, Group, Yoshitake Masuda

Electroceramics Group develops ceramic nanomaterials and electronic ceramic

devices. Our research includes:

Development of ceramic nanomaterials with aqueous solution processes

Development of platinum-substituting high-temperature conductive oxid

Development of “bulk-response type” gas sensor materials

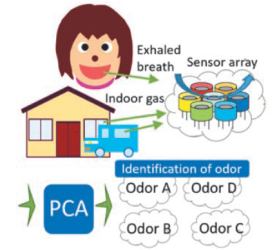

Development of gas sensors for VOCs, exhaled breath, skin gas, indoor gas,

etc.

Development of odor identification technology using sensor array and machinelearning

Development and commercialization of thermoelectric power generation modules

Light and Heat Control Materials Group

Leader, Group, Chihiro Urata

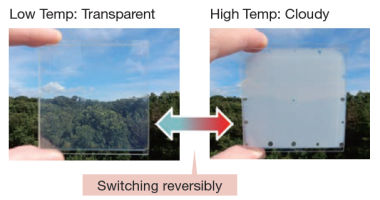

We are developing environmentally responsive materials that change their transmittance and maintain their anti-adhesion function over the long term. For example, we are working on the development of optical switching materials that control the amount of sunlight that flows into rooms and vehicles to realize energy-saving and comfortable spaces, and surface materials that support safe and secure living and energy creation by controlling snow and ice adhesion on road signs, solar panels, and other surfaces.

Energy Storage Materials Group

Leader, Group, Ken-ichi Mimura

Energy Storage Materials Group promotes research and development on novel ceramic materials, process technologies, characterization technologies, and numerical simulation to realize next-generation energy storage devices such as all-solid-state batteries and ceramic capacitors, which are expected to be applied to mobility systems and IoT devices.

Solid State Ionics Materials Group

Leader, Group, Hirofumi Sumi

In order to realize solid oxide fuel cells (SOFC), electrolysis cells (SOEC) and protonic ceramic fuel cells (PCFC), w hich are energy and chemical conversion systems with high efficiency, we are developing new solid state ionics materials such as nanocomposite electrodes, and innovative fabrication processes such as low-temperature sintering for electrolytes. And, we are demonstrating fuel cells using multi-fuels (e.g. liquefied petroleum gas (LPG) and ethanol) for power sources of small mobile applications such as robots and drones.

Nanoporous Materials Group

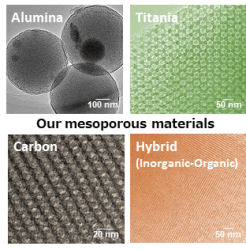

Leader, Group, Tatsuo Kimura

Towards the proposal of a new industrial structure including the realization of a circular economy through the design of function, the renewal of property, the exploring of novel applications, etc., that cannot be completed by using conventional technologies only, we are aiming to develop inorganic based materials for chemical transformation and then enhance their utilization technologies by making a full use of various nanostructural controls based on our original approach for the porous materials design as the core technology.

Next-generation Permanent Magnet Materials Group

Leader, Group, Yusuke Hirayama

We are developing post-neodymium magnets such as samarium alloy and metastable alloy in order to overcome the resource problem and low heat resistance of neodymium magnets, which are the key to EV motors. In particular, because the performance of magnets is significantly affected by microstructures, we focus on the creation of new powder metallurgy processes.

Functional Magnetic Materials Group

Leader, Group, Shusuke Okada

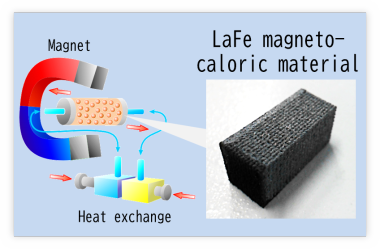

To realize a sustainable carbon-free society, we are developing soft magnetic materials that improve the energy efficiency of power electronics and mobility, together with solid-state caloric materials characterized by the magnetic entropy. Especially, the Fe-based magnetic refrigerants and the VO2 / NiTi-based heat storage materials are aimed at social implementation by realizing new applications such as magnetic heat pump and active heat storage.