Research Groups

Methane Hydrate Production Technology Research Group

In the development of natural methane hydrate resources, which are expected as newly methane resources for blue hydrogen and blue ammonia, we study a natural core characteristic analysis that contributes to a reservoir modeling for productivity evaluation of natural methane resources. We are also trying to reduce CO2 emissions for the development of carbon-neutral methane resources, such as carbon fixation with CO2 hydrate and CO2 separation using gas hydrates. Furthermore, we are conducting research and development to industrially utilization of gas hydrate through understanding the uniquely fundamental properties of gas hydrate (thermal properties and guest-host interaction).

Keywords:Carbon resource, Natural methane hydrate, Pressured-core analysis, Gas hydrate, CCUS

- a) Pressurized natural hydrate-bearing sediment core sample (Nankai trough) via PNATs system

- b) Core sample vessels

- c) In situ analysis apparatus for Hydro-mechanical properties

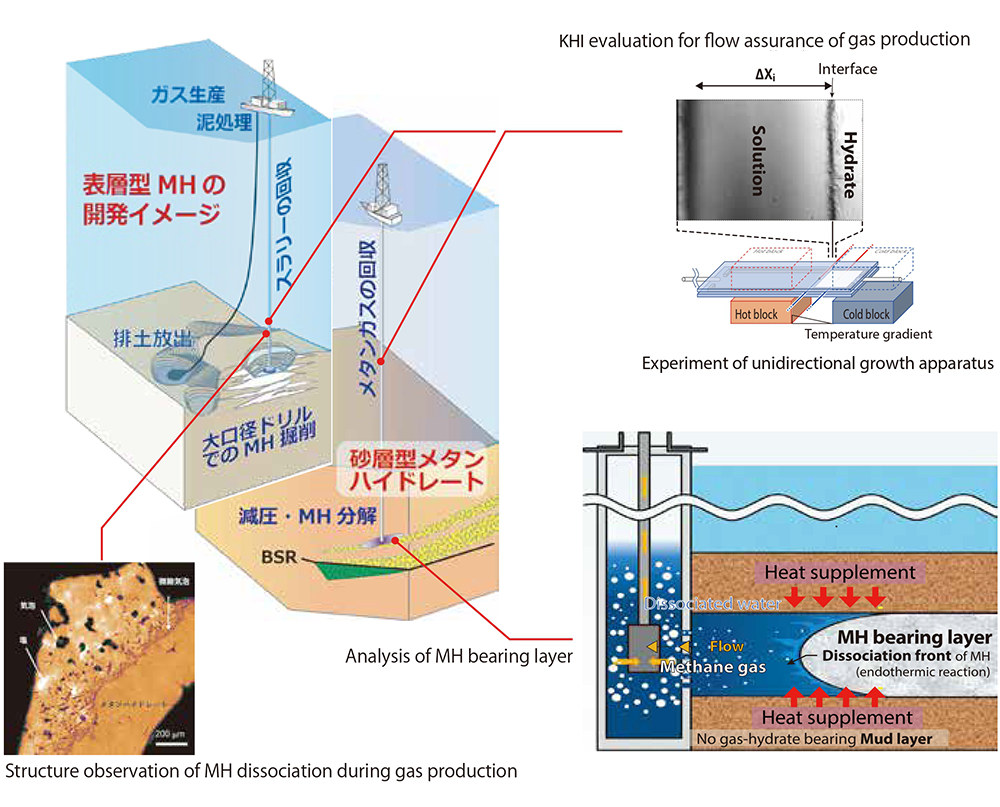

Methane Hydrate Development System Research Group

Our research and development aim is methane gas production from subsea methane hydrates (MHs) around Japan, which can be used also as a future hydrogen source. We research the essential technologies for both of MHs reservoir, which are the sand pore-filling type (MH-bearing sand reservoir) and the bulky MH within shallowclayey sediments (shallow MH reservoir). For this purpose, we are studying the MHs' reservoir analysis and evaluation, gas production method from MHs, the recrystallization/dissociation process of MH for flow assurance, inhibitor, gas separation and the feasibility study of CO2 storage technology within the MH reservoirs. Especially, inhibitor and gas separation studies have to need the essential understanding of clathrate hydrate crystallization and dissociation, so that we are investigating physical properties of clathrate hydrates not only the gas hydrate in micro-scale to field-scale based on crystallography and thermodynamics. We will develop the clathrate hydrate studies that cover the technologies for using various industrial applications, continuously.

Keywords: Methane hydrate resource development, Industrial application of clathrate hydrates, Crystal structure and growth analysis for Hydrate inhibitor, Exploration for Semiclathrate hydrates

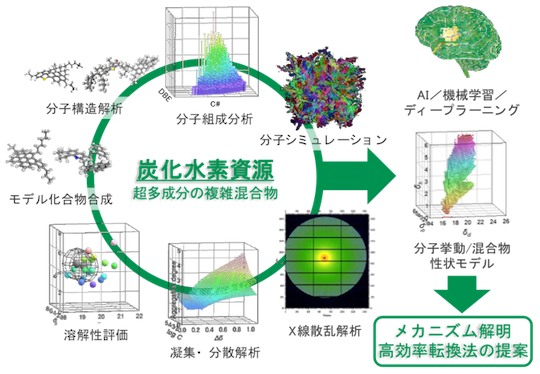

Hydrocarbon Resources Conversion Research Group

We conduct researches about analytical technologies and process design technologies for effective

conversion of hydrocarbon resources, such as biomass, wastes, petroleum, and coal, which are complex

mixture of various kinds of hydrocarbon molecules. Our detailed analytical technologies clarify

the mechanism of phenomena and help to develop novel conversion processes. Our process design

technologies optimize the whole system of conversion processes in nano/micro/macro scales:

molecular reaction/reactor/process/society/environment.

Keywords: Hydrocarbon resource, Biomass, Wastes, Petroleum, Coal, Asphaltene, Coke, Molecular structure analysis, Process analysis, Pretreatment, Extraction, Pyrolysis, Gasification, Catalytic cracking, Fouling

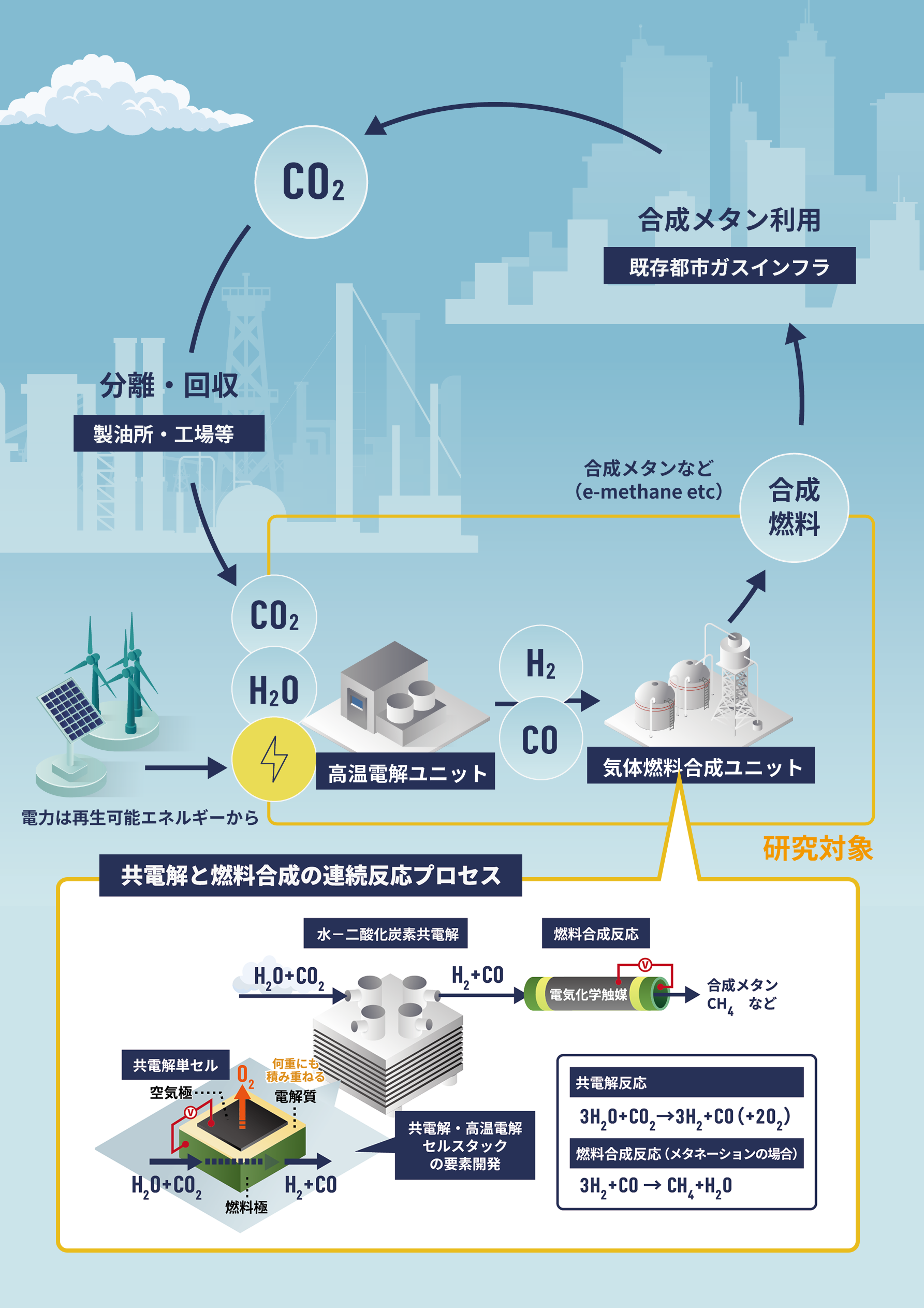

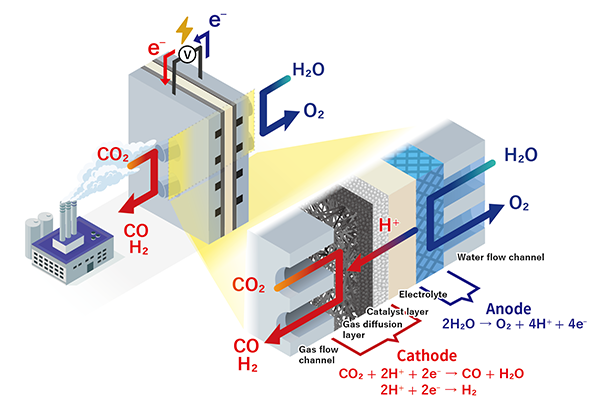

Energy Conversion Process Research Group

To realize a sustainable carbon neutrality, energy conversion process Research Group engages in comprehensive research activities on development of new technologies for clean and efficient usage of conventional hydrocarbon resources such as coal and natural gas. We are working on research works for the novel CCU (Carbon Capture and Utilization) process which can convert CO2 to fuel, syngas or valuable chemicals in conjunction with electricity/hydrogen derived from renewable energy. We deploy energetic research activities on the innovative thermochemical or electrochemical energy/material conversion processes, based on the fluidized bed technology, catalytic chemistry, gasification/pyrolysis technology and electrochemical device technology.

Keywords:Fossil fuels, Renewable energy, Hydrogen, CO2 utilization, Thermochemical conversion process

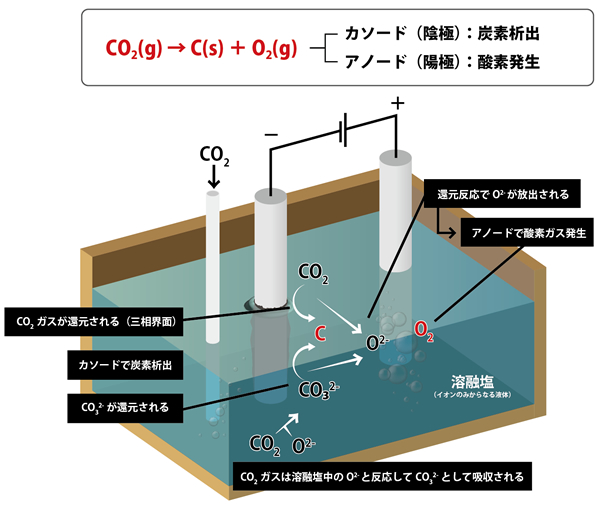

Energy Conversion Materials Research Group

Social implementation of various innovative technologies is urgently required under the “Green Growth Strategy through Achieving Carbon Neutrality in 2050 (METI, Japan)”. We are conducting research and development on the related technologies with Green Growth Strategy. Specifically, solid-oxide steam electrolysis (SOEC), highly effective PtoGas (e-methane) technology combined with co-electrolysis and recycled carbon fuel synthesis reaction, direct electrolysis of CO2 to solid carbon and O2 in high-temperature molten salts (PtoSolid technology) etc. are being developed through internal/external cooperation.

Keywords:SOFC-SOEC electrochemical cell, Co-electrolysis, Recycled carbon fuel (e-methane), Direct CO2 electrolysis and Co-produced carbon material, CO2 electrolysis operating in low to medium temperature ranges

(SOEC methanation etc.)

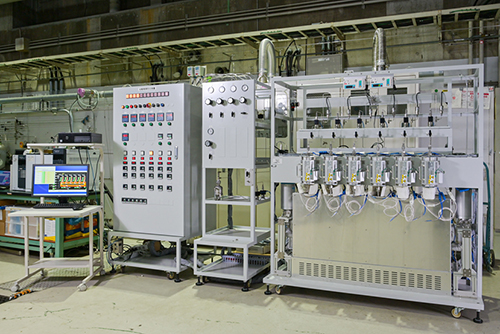

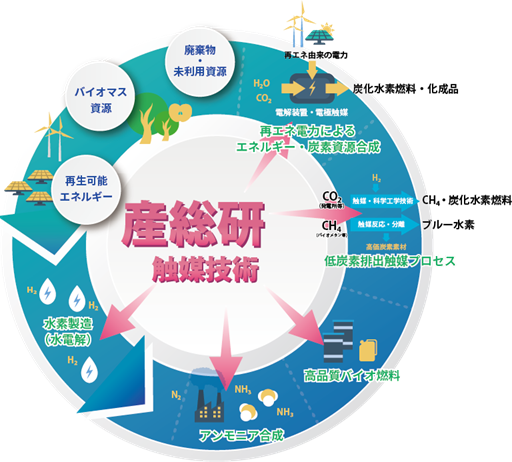

Energy Catalyst Technology Research Group

To realize a low-carbon society, our Research Group aims to develop advanced catalysts combined with chemical reaction engineering and electrochemistry for extensive utilization of renewable energy and unused energy resources, which would contribute to the carbon dioxide capture and utilization, and hence reduce CO2 emission and global warming. Currently, we are developing new catalysts and composite materials for many kinds of chemical reaction systems, which can efficient and cost-effective produce energy carriers, fine chemicals and fuels such as ammonia, methane, light hydrocarbons functional organic compounds and biofuels using renewable hydrogen, biomass, waste and recyclable CO2 as feedstocks. We are also studying on new chemical engineering and reaction system, which can utilize renewable electricity for the purpose as aforementioned.

Keywords:Catalysts, Carbon recycling, Synthetic fuels, Electrochemical, Hydrogen・Energy carriers, Biofuel

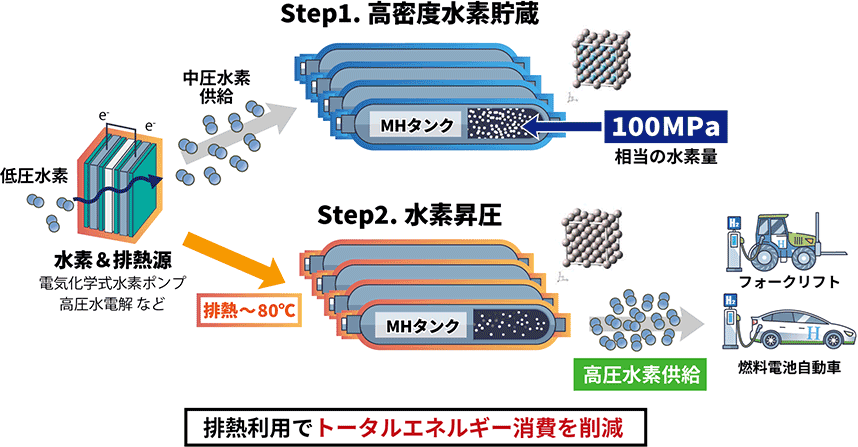

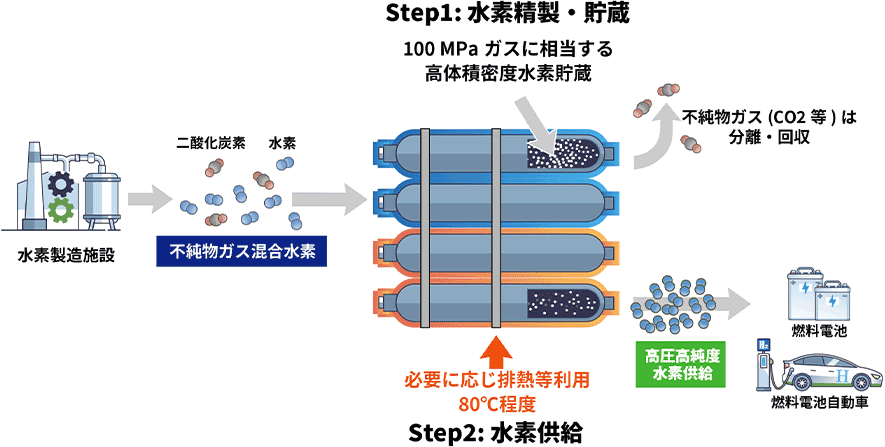

Hydrogen Energy Materials Research Group

To promote reliable and economical Hydrogen Society, we are developing highly durable high-capacity metal hydrides for hydrogen storage systems. In addition, based on the characteristics of metal hydrides, deeply understood through our fundamental studies using in-situ testing apparatuses, we are working on supplementary functionalities such as thermochemical hydrogen compressors and hydrogen purification.

Keywords:hydrogen storage, hydrogen compression, FCV, H2 refueling station