Research

The main research themes of this laboratory include bonding interface evaluation, development of new adhesive materials, strength and reliability evaluation of adhesive joints, and development of surface treatment and testing methods. The most important endeavor of this laboratory is to promote industry-academia-government collaboration through various projects. If you have a technical problem, please contact us without hesitation.

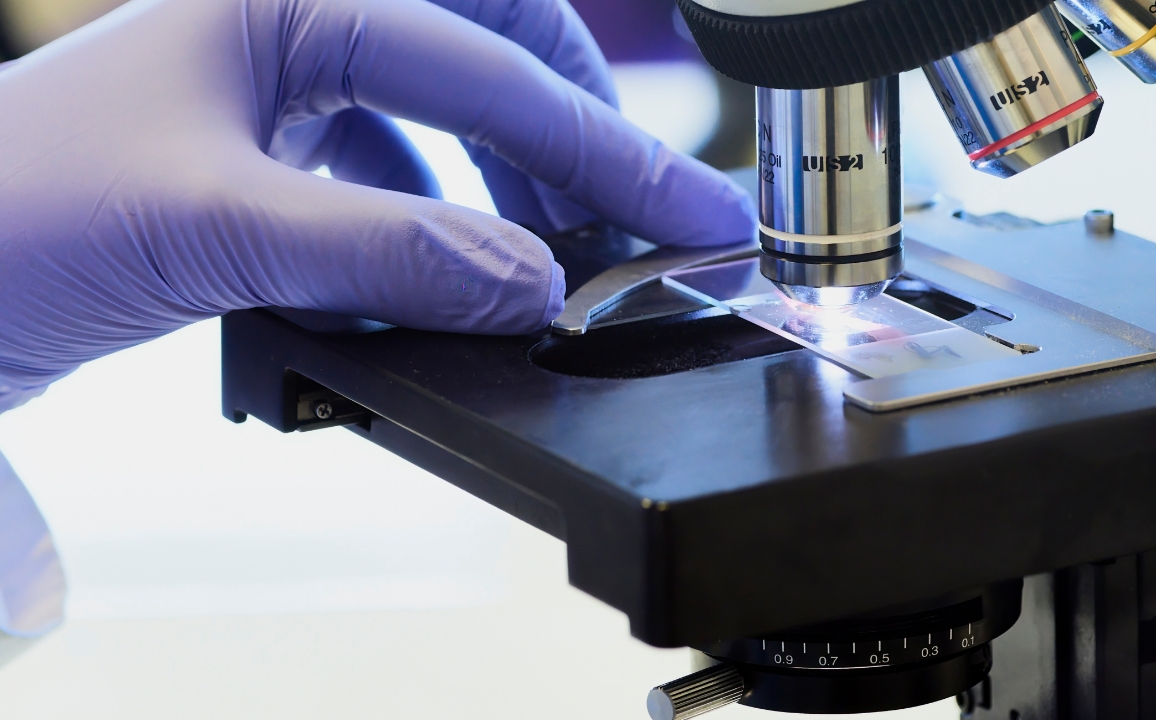

Next, interface analysis

This research comprehensively analyzes the chemical bonding state, microstructure, and interfacial reactions at adhesive interfaces. Using techniques such as electron microscopy and spectroscopic analysis, we elucidate the reaction products and stress distributions occurring at the interface to identify the factors governing adhesive strength and durability. This provides fundamental insights necessary for optimizing interface design and improving adhesive materials, aiming to establish long-term reliable adhesive technology.

Development of New Adhesive Materials

This research aims to develop a novel adhesive material with high strength, high heat resistance, and low environmental impact. By combining molecular design and organic synthesis techniques, we will achieve both excellent mechanical properties and durability through structural control. We will also pursue sustainable material design that considers reusability and recyclability. This approach targets the creation of high-performance adhesives applicable across diverse fields such as automotive, electronics, and aerospace.

Strength and Reliability Evaluation of Adhesive Joints

This study quantitatively evaluates the strength and reliability of adhesive joints. By combining experiments such as tensile and shear tests with finite element analysis, we analyze stress concentration and crack propagation behavior. We also investigate the effects of environmental factors like temperature and humidity changes and fatigue loading on joint degradation, constructing an evaluation model to predict long-term reliability. This aims to establish joint design guidelines that balance safety and durability.

Development of Surface Treatment Methods and Inspection Techniques

This research aims to develop a novel surface treatment method to enhance adhesion and establish inspection techniques capable of evaluating its effectiveness with high precision. Surface modification will be achieved through plasma treatment and chemical processing to optimize surface energy, roughness, and functional group distribution. Additionally, optical and electrical inspection technologies enabling non-destructive evaluation of interface quality will be developed for application in quality control during the manufacturing process.

Furthermore, the development of laser processing technology has enabled long-term stability of the bonded interface exceeding 10 years.