We have completely renewed our website.

We will continue to improve the content, so we appreciate your continued support.

Research

The main research themes of this laboratory include bonding interface evaluation, development of new adhesive materials, strength and reliability evaluation of adhesive joints, and development of surface treatment and testing methods. The most important endeavor of this laboratory is to promote industry-academia-government collaboration through various projects. If you have a technical problem, please contact us without hesitation.

Introduction to the Adhesion and Interface Phenomena Research Laboratory

[AIST Official]

In recent years, heterogeneous material joining technologies have gained attention for reducing the weight of automobiles and aircraft.

In response to this societal demand, AIST established the “Adhesion and Interface Phenomena Research Laboratory”

in 2015 to enhance international competitiveness and develop a hub for adhesive bonding.

Furthermore, to strengthen industry-academia-government collaboration,

the “Adhesion and Joining Technology Consortium” was founded in 2016.

Here, we introduce AIST's broad range of research and activities concerning adhesion and joining technologies.

Translated with DeepL.com (free version)

News

Specialized equipment

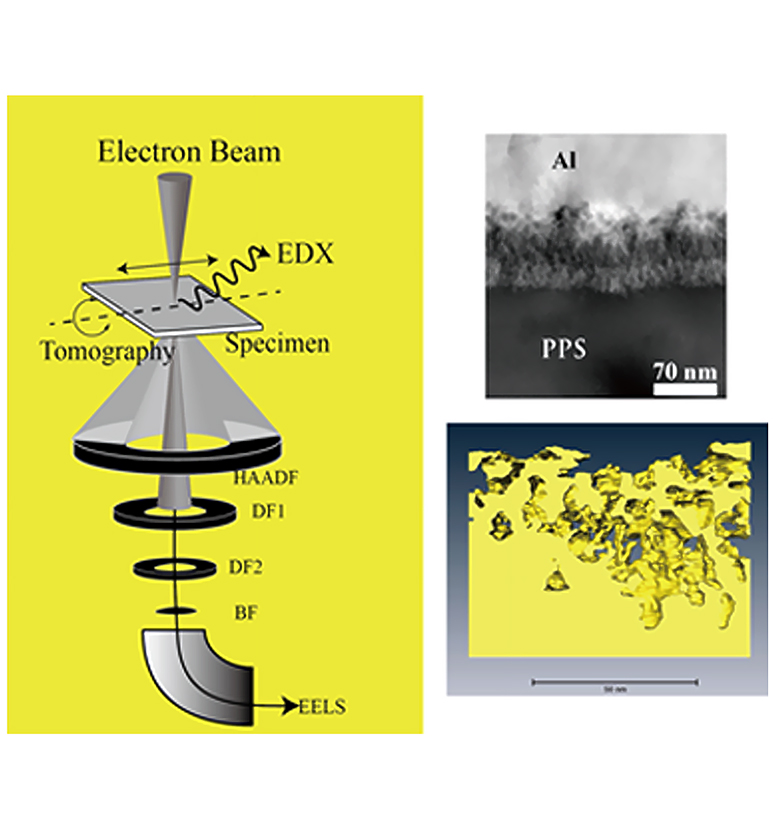

This laboratory uses STEM equipment to observe interface microstructures and elemental distributions with high precision.

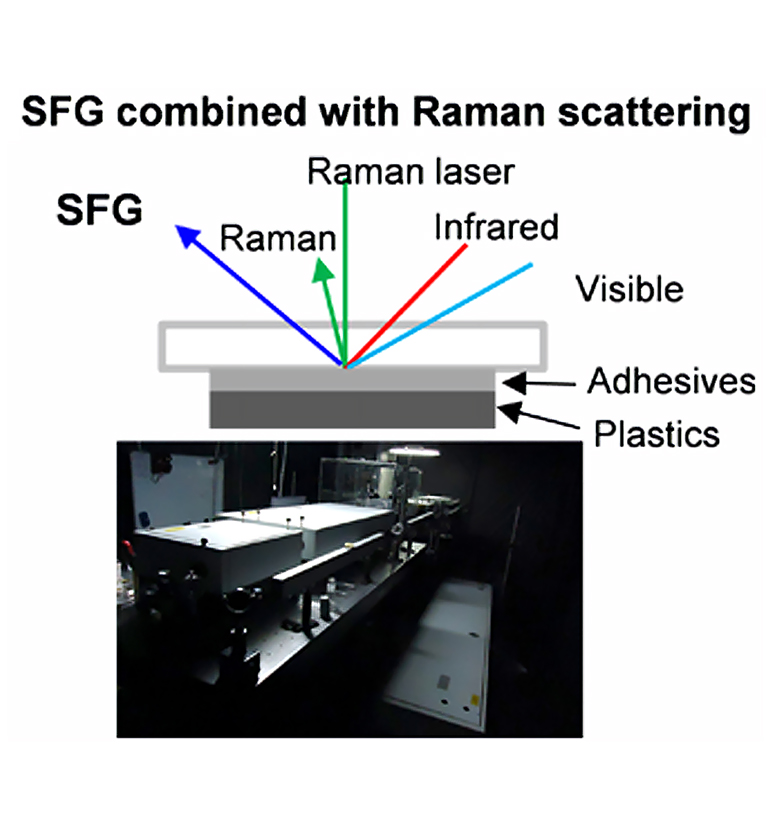

The sum-frequency generation (SFG) instrument non-destructively measures the orientation of interface molecules, enabling molecular-level analysis of adhesion reactions.

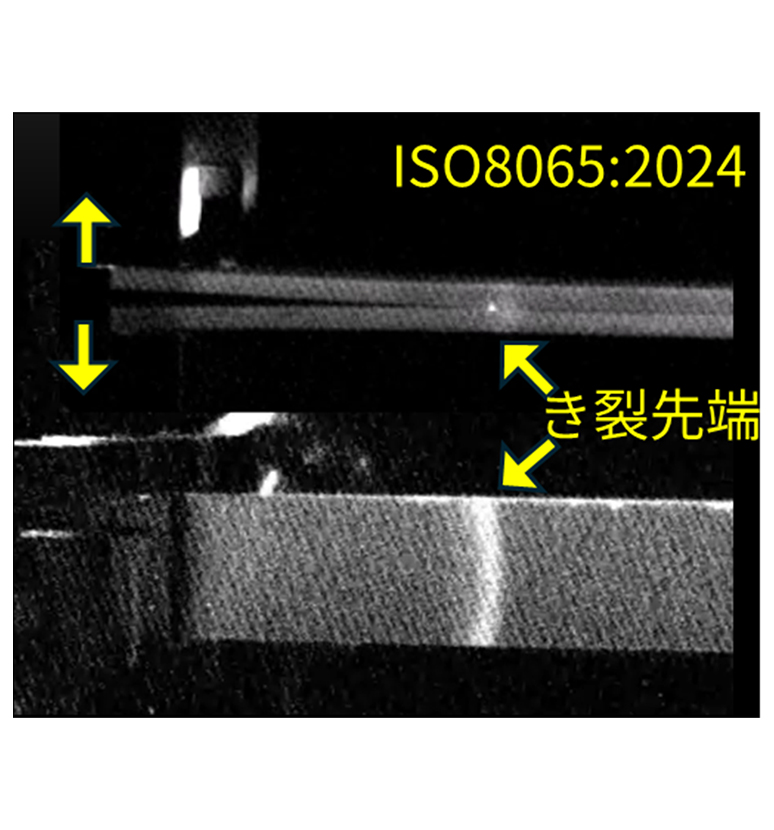

Stress-induced luminescence technology visualizes dynamic strain distributions and is internationally standardized.

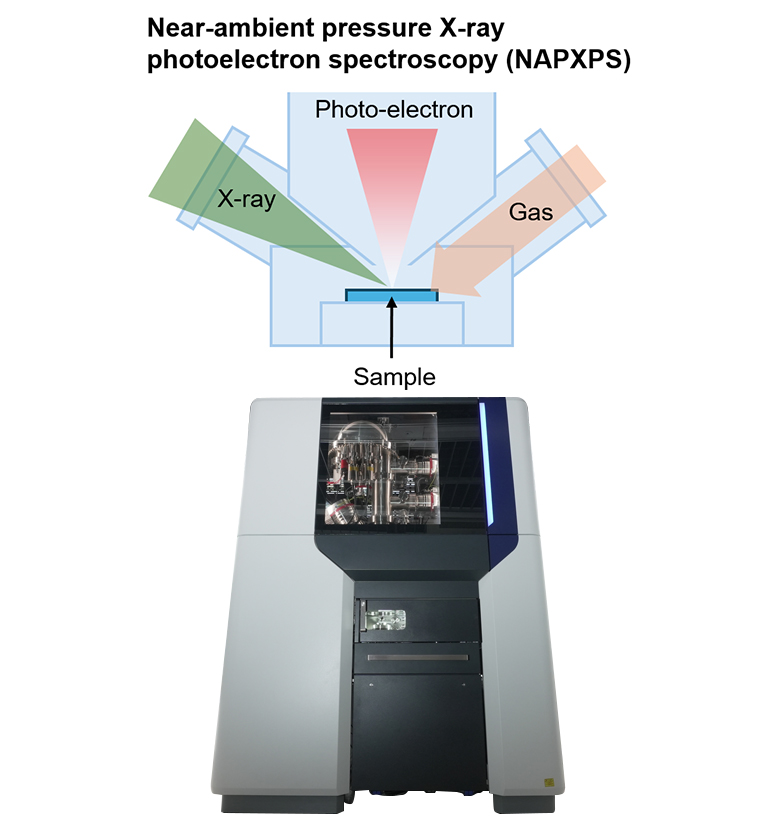

The Near-Atmospheric Pressure X-ray Photoelectron Spectroscopy (NAPXPS) system enables XPS measurements of solid surfaces undergoing chemical state changes in real environments and of liquid samples.

Translated with DeepL.com (free version)

STEM device

The STEM device is a high-resolution electron microscope capable of analyzing the internal structure and composition of materials at the nanometer scale. Through scanning transmission observation, it enables detailed visualization of atomic arrangements, precipitates, and defect structures within bonding interfaces and thin-film materials. Combined with energy-dispersive X-ray spectroscopy (EDS), it quantitatively evaluates elemental distribution, aiding in elucidating interface reactions and material degradation mechanisms.

Harmonic and Frequency Analysis (SFG) Device

Sum Frequency Generation (SFG) spectroscopy is a highly sensitive optical technique that enables non-destructive observation of molecular orientation and chemical structure specific to solid surfaces and interfaces. It analyzes sum frequency signals obtained by simultaneously irradiating infrared and visible light to detect the arrangement state of surface molecules and changes in functional groups. This technique allows for molecular-level understanding of the initial stages of adhesion and interfacial reactions.

Stress-induced luminescence technology

Stress luminescence is a technology that visualizes dynamic strain distribution by applying special coatings or sheets. This enables the detection of fracture initiation points and bonding defects. It also allows for accurate crack tracking in DCB and DNF tests used to determine fracture toughness (G1c, C2c). Its international standardization has led to its adoption worldwide.

Near-Atmospheric Pressure X-ray Photoelectron Spectroscopy (NAPXPS) System

Near-ambient pressure X-ray photoelectron spectroscopy (NAPXPS) equipment enables XPS measurements on sample surfaces under near-ambient pressure conditions, which cannot be achieved with conventional XPS systems. By irradiating the sample surface with X-rays and detecting the emitted photoelectrons with a detector, the chemical states of each element can be investigated. The capability to perform XPS measurements at near-ambient pressure enables the study of chemical state changes occurring on solid surfaces in real-world environments and allows XPS measurements on liquid samples.