Non-destructive Measurement Group

Non-destructive Measurement Group

The manufacturing process of PAN-based carbon fibers was filed for the patent by Dr. A. Shindo who was a researcher at the Osaka National Research Institute (currently, AIST Kansai) in 1959.

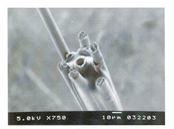

Since then, we have evaluated the physical properties of carbon fibers and their composites and have developed several evaluation testing methods. We investigate the factors to control the physical properties of carbon fibers fabricated from various precursors through observation of crystal structures and feature of the cross-section.

.png)

.png)

A research program on new development of PAN-based carbon fibers has started since 2012.

Our research target is to evaluate mechanical properties of carbon fibers and their composites developed in this research program and to establish standardization of their testing methods.

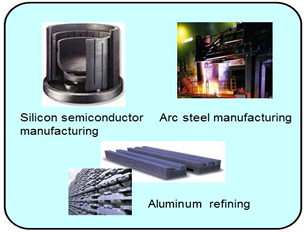

【Carbon Materials (manufacturing industry use)】

Many artificial carbon materials are utilized at a high temperature for refining steel, aluminum and silicon semiconductor,etc. For such applications, it is important to understand the physical properties of carbon materials at high temperatures.

We have developed some special instruments for measuring the physical properties of carbon materials at high temperature over 2000℃ in Argon atmosphere. We have reported temperature dependence of mechanical properties, electrical resistance and thermal diffusivity ranging from room temperature to 2600℃. Temperature dependence of these physical properties are critical for optimizing the manufacturing conditions of graphite products.

Measureable properties (tests):

・ Mechanical properties (bending and tensile tests)

・ Resistivity

・ Thermal diffusivity

・ Thermal expansion

Non-destructive Measurement Group

Research Institute for Measurement and Analytical Instrumentation

AIST Tsukuba Central2 1-1-1 Umezono Tsukuba Ibaraki 305-8568 JAPAN