Non-destructive Measurement Group

Non-destructive Measurement Group

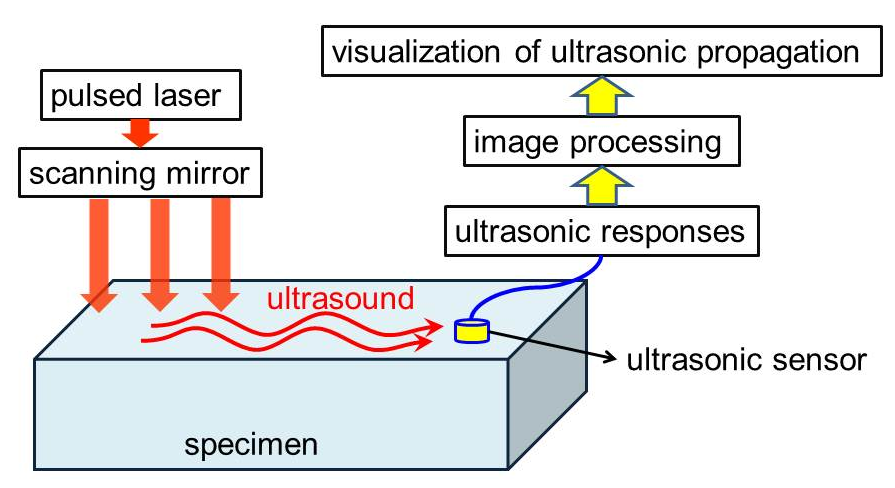

Ultrasonic inspection is commonly used in non-destructive inspection. We are developing a novel damage detection technique in which ultrasound propagation is visualized. In this technique, ultrasonic excited by a pulsed laser is scanned on the entire surface of a monitored structure by utilizing a MEMS mirror, and the ultrasonic responses are detected with an ultrasonic sensor attached on the surface of the structure. Ultrasonic propagation can be visualized from the data on the location of ultrasonic excitation and the corresponding ultrasonic responses. Compared with conventional ultrasonic inspection, the developed technique allows easy and fast inspection not only for simple-shaped structures but also for complex-shaped structures.

Recent research subjects are as follows:

(1) resolution enhancement of defect detection

(2) image processing technique for visualizing ultrasonic propagation

(3) system development for completely non-contact inspection

The developed ultrasonic visualization system is commercially available from

a venture company based on AIST technology transfer named Tsukuba Technology, Co., Ltd.

Non-destructive Measurement Group

Research Institute for Measurement and Analytical Instrumentation

AIST Tsukuba Central2 1-1-1 Umezono Tsukuba Ibaraki 305-8568 JAPAN