Research Institutes

Research Institutes of NMIJ conduct research and development towards the establishment of primary standards (measurement standards), and dissemination of the measurement standards to societies and industries In cooperation with the Center for Quality Management of Metrology (Metrology Quality Office, Reference Materials Office, Metrology Training Center and Legal Metrology Management Office),.

NMIJ has four research institutes: Research Institute for Engineering Measurement; Research Institute for Physical Measurement; Research Institute for Material and Chemical Measurement; and Research Institute for Measurement and Analytical Instrumentation.

They also carry out technological tasks to link the national measurement standards with those of other countries as well as performing tasks for the government to maintain the accuracy of measuring instruments (specified measuring instruments) necessary for all types of business, taxation, safety and regulations.

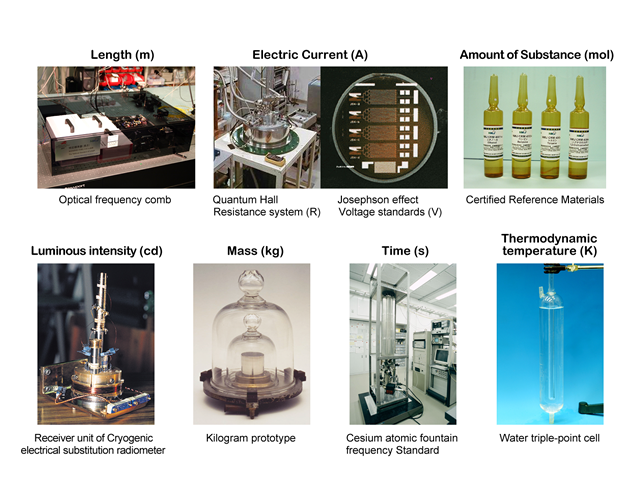

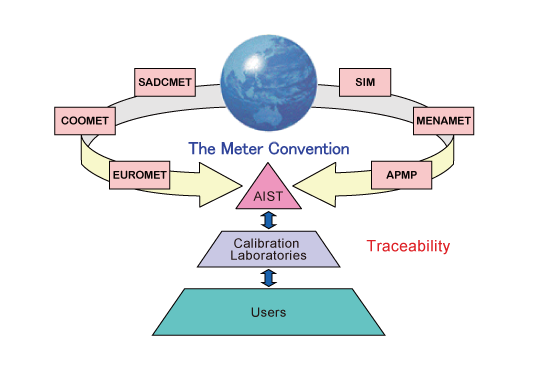

The measurement standards consist of seven base units as shown in Fig.1, and derived units are formed as products of powers of the base units. Research Institutes collaborate with other countries and develop global mechanisms to maintain the equivalence of the measurement standards among domestic and international users. (traceability and mutual recognition arrangement: Fig.2)

Research Institutes Carry Out Tasks Related to Measurement Standards with the Following Goals

- To provide reliable measurement standards promptly at the social request.

- To disseminate measurement standards reliably and continuously..

- To accommodate global standardization of measurement standards under international collaboration.

- To carry out research and development of measurement standards as leading laboratories

Structure of Research Institutes of NMIJ

Measurement Standards for Environment, Health and Safety

Reference Materials for Maintaining a Comfortable Environment

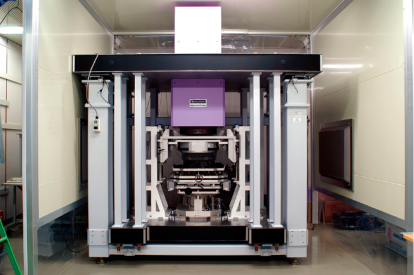

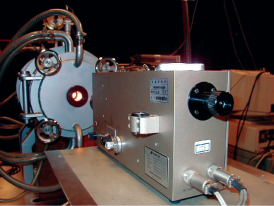

Ear thermometers are novel thermometers sensing infrared radiation emitted by the human body. They are being widely used at airport facilities of various countries to test for SARS infection in individuals. The photograph shows the standard blackbody system for the calibration of ear thermometers developed by MD. It is a transportable high-accuracy standard blackbody system that was supplied to overseas institutes such as those in Singapore, and its use contributed effectively to prevention of a SARS epidemic in Asian countries.

Gamma-ray Standards Contributing to Human Safety

Radio waves used in cell phones and wireless LANs became essential in daily life. It is necessary to utilize a space in which the minimum possible scattering and reflection of waves from the surroundings are ensured to enable accurate measurement of the strengths of electric and magnetic fields and standard antennas. An open-area test site is used as an outdoor measurement field for the frequencies from 30 MHz to 1 GHz. An electromagnetic anechoic chamber (24 m x 15 m x 9 m) with surrounding walls, a ceiling and a floor constructed as close to nonreflecting as possible, is used as an indoor measurement field for frequencies of up to 40 GHz.

Calibration Facility for Infrared Ear Thermometers Contributing to Prevention of a SARS Epidemic

Radio waves used in cell phones and wireless LANs became essential in daily life. It is necessary to utilize a space in which the minimum possible scattering and reflection of waves from the surroundings are ensured to enable accurate measurement of the strengths of electric and magnetic fields and standard antennas. An open-area test site is used as an outdoor measurement field for the frequencies from 30 MHz to 1 GHz. An electromagnetic anechoic chamber (24 m x 15 m x 9 m) with surrounding walls, a ceiling and a floor constructed as close to nonreflecting as possible, is used as an indoor measurement field for frequencies of up to 40 GHz.

Measurement Facility for Electromagnetic Fields and Antenna Standards

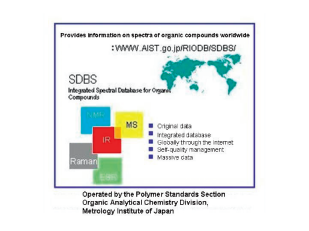

Spectral Database Essential for Chemical Analyses

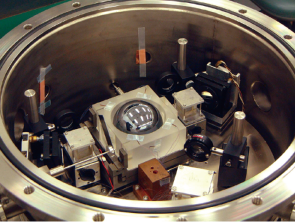

Gamma-ray and X-ray are used in the vicinity of nuclear facilities, and for medical diagnosis and therapy; it is important to measure these rays accurately to ensure human safety and health. National standards for gamma-ray are established using the graphite cavity ionization chamber shown in the photograph. The values of personal monitors used in the vicinity of facilities utilizing ionizing radiation are calibrated on the basis of the reference standards of MIJ.

Measurement Standard Technology Contributing to Industries

Flatness Measurements Essential to the Semiconductor Industry

Gamma-ray and X-ray are used in the vicinity of nuclear facilities, and for medical diagnosis and therapy; it is important to measure these rays accurately to ensure human safety and health. National standards for gamma-ray are established using the graphite cavity ionization chamber shown in the photograph. The values of personal monitors used in the vicinity of facilities utilizing ionizing radiation are calibrated on the basis of the reference standards of MIJ.

High-accuracy Angle Standard for Use in Robots

High-accuracy angle measurements are required in places such as the arm joints of robots and the rotation mechanism of paper feeders of printers; rotary encoders are used in many of these places.

To calibrate high-accuracy rotary encoders, MIJ succeeded in developing a rotary encoder angle self-calibration system with the world's highest accuracy, enabling calibration at an accuracy of approximately 0.01" using the equal division averaged method (Masuda-Kajitani method).

(Collaborative research with Shizuoka Institute of Science and Technology and University of Electro-Communications)

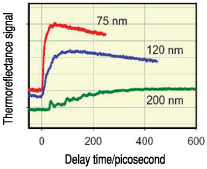

Measurement of Thin-Film Thermophysical Properties and Reference Thin-Film

A pico-second thermoreflectance measurement system has been developed in order to measure thermal diffusivities of thin films thinner than 1 micrometer. A film face of a transparent substrate side is heated by a pico-second laser pulse. Heat generated by the pump laser pulse diffuses towards the front surface of the thin film. The temperature change on the front surface opposite to the heated area is measured by the reflected intensity of probe pico-second laser pulse. The heat diffusion across molybdenum thin films with thickness of 75, 120, and 200 nm has been observed successfully for the first time in the world. Based on this technique, MIJ are now developing the thin film thermal diffusivity standard and reference thin films for thermal diffusivity measurements.

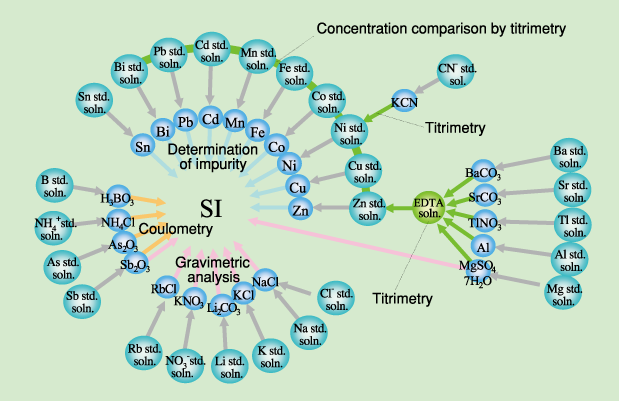

Common Measures for Chemical Analysis

A pico-second thermoreflectance measurement system has been developed in order to measure thermal diffusivities of thin films thinner than 1 micrometer. A film face of a transparent substrate side is heated by a pico-second laser pulse. Heat generated by the pump laser pulse diffuses towards the front surface of the thin film. The temperature change on the front surface opposite to the heated area is measured by the reflected intensity of probe pico-second laser pulse. The heat diffusion across molybdenum thin films with thickness of 75, 120, and 200 nm has been observed successfully for the first time in the world. Based on this technique, MIJ are now developing the thin film thermal diffusivity standard and reference thin films for thermal diffusivity measurements.

New Measurement Standards

Atomic Clock with an Error of 1 Sec Per 20 Million Years

The thermal motion of atoms was the most significant factor limiting the accuracy of time standard. MIJ has developed a high-accuracy atomic clock the error of which is only 1 sec per 20 million years by freezing the motion of atoms using pressure generated by a laser beam. The high-accuracy atomic clock is used to monitor and calibrate the coordinated universal time, which is the foundation of today's time system.

Proposal for a New Mass Standard Replacing the Prototype of the Kilogram

The kilogram is the only SI base unit still defined by an artifact, the prototype of the kilogram. For replacing the present definition of the unit to an atomic mass standard that is traceable to the mass of a single 12C atom, the Avogadro constant is being determined at MIJ by the X-ray crystal density method. This method determines the Avogadro constant by absolute measurements of the lattice constant using an x-ray interferometer, density using an optical interferometer and molar mass using a mass spectrometer for an identical silicon crystal. To realize the new definition, the Avogadro constant must be determined with a reduced uncertainty. For this purpose, technologies that measure the lattice constant, density and molar mass more accurately are being developed.

New Temperature Scale for Ultra-high Temperatures Exceeding 1000 °C

A temperature scale exceeding 1000 °C is essential in the technological development in various fields such as space and aeronautical materials, nuclear materials, and nuclear fusion.

Conventionally, temperature fixed points for realizing temperature scale has been defined up to approximately 1100 °C.

MIJ is the first to realize fixed points of alloys of metal and carbon as temperature standards for temperature regions exceeding 3000 °C.

In the photograph below, on the left, light is radiating from a black body into which a eutectic alloy of iridium and carbon is cast at its melting point, approximately 2300 °C.

On the right, a radiation thermometer is calibrated based on the intensity of the radiation.

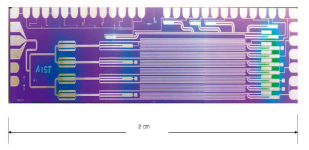

Worlds First Liquid-Helium-Free Voltage Standard

MIJ is developing a "liquid helium-free programmable Josephson voltage standard" using an NbN/TiN/NbN device that is operable at approximately 10 K using a small freezer as the next generation voltage standard. If this system is introduced, not only will liquid helium, which is essential in conventional systems, become unnecessary, but a substantial reduction in the price of the system and in the maintenance cost will be realized. In the near future, high-accuracy voltage standards can be generated solely based on the availability of a 100 V AC power source.