About CMT-RI

The Core Manufacturing Technology Research Institute (CMT-RI) of AIST has worked on research and development for MONOZUKURI (= manufacturing) technologies since 1937 as former Mechanical Engineering Laboratory by 2001, with responding to needs of industries. In the last decade, the concept of “smart manufacturing” with applying IoT technologies has become key to create new business opportunities with increasing productivity and also to succeed masters’ skills. However, we believe that the "manufacturing science" must be foundation of competence in MONOZUKURI. The cutting-edge manufacturing technologies would be established through scientific understanding of manufacturing processes and development of optimal process chain (consist of design, processing, and evaluation) that realizes requirement functions and higher values. And then, the latest information technologies such as IoT and AI should be applied for innovating novel manufacturing system to maximize value of products. We are data-scientists researching data-driven manufacturing technology, deepening collaboration with industry, and creation of innovative manufacturing technologies full of originalities and ingenuity.

Groups

-

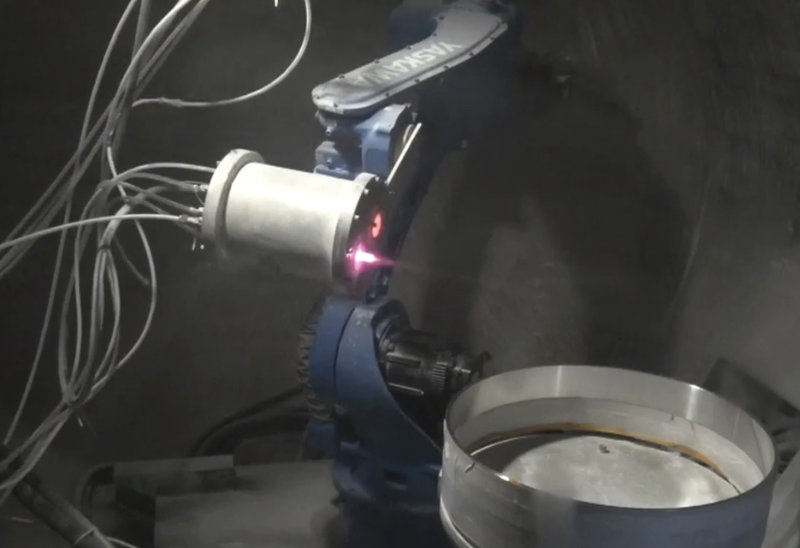

Remanufacturing Research Group Our group is promoting research and development of novel repair technologies toward leveraging the diversification of remanufacturing process, covering the amplification of composition and crystal structure formation control of objects manufactured through additive manufacturing process, enhancing the quality of the metal powder particles, and advancing the in-situ evaluation technology through the use of ultrasonic measurement.

Remanufacturing Research Group Our group is promoting research and development of novel repair technologies toward leveraging the diversification of remanufacturing process, covering the amplification of composition and crystal structure formation control of objects manufactured through additive manufacturing process, enhancing the quality of the metal powder particles, and advancing the in-situ evaluation technology through the use of ultrasonic measurement. -

Surface Functionalization and Tribology Reserch Group The Tribology Group conducts research and development to solve various problems related to friction, wear, and lubrication. The issues are important not only in industrial machineries, but also in transportation equipment, home applianeces, and even in products not related to machinery. We continuously make efforts to elucidate mechanisms, improve characteristics, and optimize design regarding tribological phenomena. We aim to support industries and contribute to the realization of a sustainable society.

Surface Functionalization and Tribology Reserch Group The Tribology Group conducts research and development to solve various problems related to friction, wear, and lubrication. The issues are important not only in industrial machineries, but also in transportation equipment, home applianeces, and even in products not related to machinery. We continuously make efforts to elucidate mechanisms, improve characteristics, and optimize design regarding tribological phenomena. We aim to support industries and contribute to the realization of a sustainable society. -

Coatings and Interface Engineering Research Group The Coatings and Interface Engineering Research Group conducts research and development of microstructured surface functions. We aim to develp surface functions that enable controls of optical peoperties, wetting and slipping peoperties. We conduct research based on our competence of surface micro-nano fabrication, polymer/inorganic materials, and molding/structural design. We closely collaborate with universities and industries aiming to produce inductrial innovation.

Coatings and Interface Engineering Research Group The Coatings and Interface Engineering Research Group conducts research and development of microstructured surface functions. We aim to develp surface functions that enable controls of optical peoperties, wetting and slipping peoperties. We conduct research based on our competence of surface micro-nano fabrication, polymer/inorganic materials, and molding/structural design. We closely collaborate with universities and industries aiming to produce inductrial innovation. -

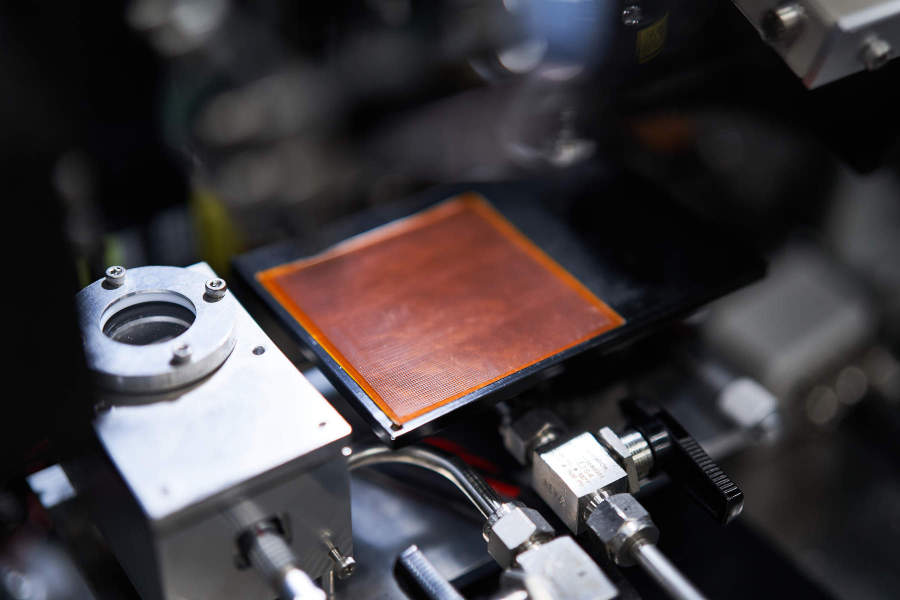

Smart Thin Film Process Design Research Group The research group works on R&D to develop materials and devices that achieve high functionality and minimum consumptions of enery and materials. The topics include: (1) development of high functionality materials using novel coating technology (saving energy in manufacturing and advancing the functionalities); (2) deveice remanufacturing by repair and upgrades; and (3) life cycle assessment (LCA), reliability evaluation, design for remanufacturing (DfRem), and life cycle engineering (LCE).

Smart Thin Film Process Design Research Group The research group works on R&D to develop materials and devices that achieve high functionality and minimum consumptions of enery and materials. The topics include: (1) development of high functionality materials using novel coating technology (saving energy in manufacturing and advancing the functionalities); (2) deveice remanufacturing by repair and upgrades; and (3) life cycle assessment (LCA), reliability evaluation, design for remanufacturing (DfRem), and life cycle engineering (LCE). -

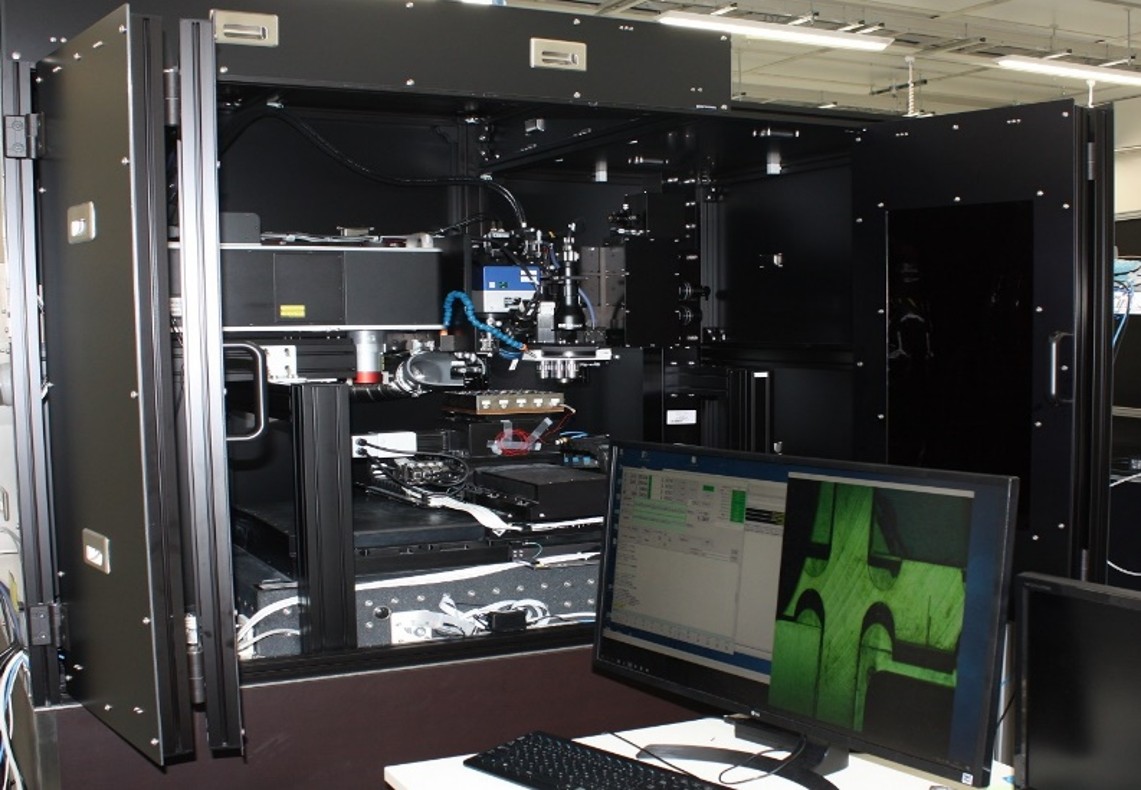

Laser Processing Frontier Research Group Laser processing, which uses high-density energy laser beams, contributes to industry as a highly efficient manufacturing technology. Our group is working with companies in diverse fields to further introduce laser processing to industry. We are also focusing on pioneering the frontiers of laser processing to create new value and are committed to R&D of advanced light sources and processes such as ultrashort pulsed lasers and mid-infrared lasers, as well as data-driven laser processing based on in-process monitoring and AI.

Laser Processing Frontier Research Group Laser processing, which uses high-density energy laser beams, contributes to industry as a highly efficient manufacturing technology. Our group is working with companies in diverse fields to further introduce laser processing to industry. We are also focusing on pioneering the frontiers of laser processing to create new value and are committed to R&D of advanced light sources and processes such as ultrashort pulsed lasers and mid-infrared lasers, as well as data-driven laser processing based on in-process monitoring and AI.