Theme

Study of wire-fed additive manufacturing technology using laser

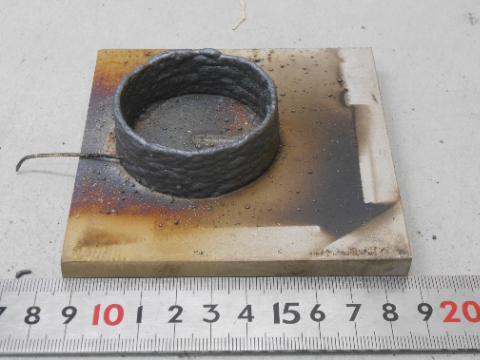

- Example of circle wall deplosition

- Example of liner wall deposition

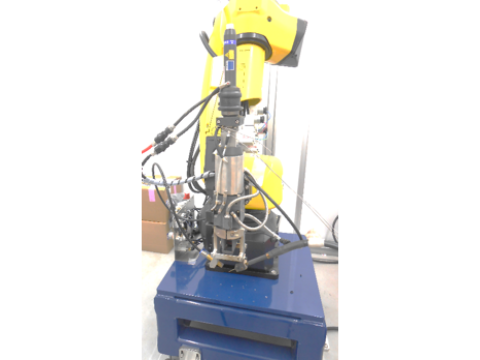

- Photo of wire DED machine

Research Keyword

Laser, Melting, Filler wire, Additive manufacturing, Hot wire

Research Objectives

Metal powder is very difficult to deal and additive manufucuturing using metallpowder is difficult to laminate a big parts in short time. Therefore, to achive big volume lamination swiftly and easily, we develop additive manufucturing technology that lamination material is supplied solid like metal wire.

Research Results

We can laminate narrow width wall by suppling metal wire on llaser irradiation point and layer upon layer. In this process, lamination speed is 4kg/h. To achive higher llamination speed, we develop hot wire DED system. And lamination speed of hot wire DED system achieve 8.1kg/h. this lamination speed indicate that lthis machine can laminate big volume lwith high speed.

The process behavior of wire DED was obserbed that wire suppied molten pool and melted by laser irradiation stably. this stable behavior was continued during DED process.

In addition, we can make lnot only liner wall but also circler wall using developed wire DED machine.

Links(external publications, patents, related news, etc.)

- Naoki Seto and Hiroshi Sato,“Deposition Conditions for Laser Formation Processes with Filler Wire”, International Journal of Automation Technology (IJAT), Vol.10 No.6 pp. 899-908, (2016)

- Naoki Seto,”High efficiency of wire 3D modeling by hot wire method”, Research result reports of Amada foundation 2020、(2020)