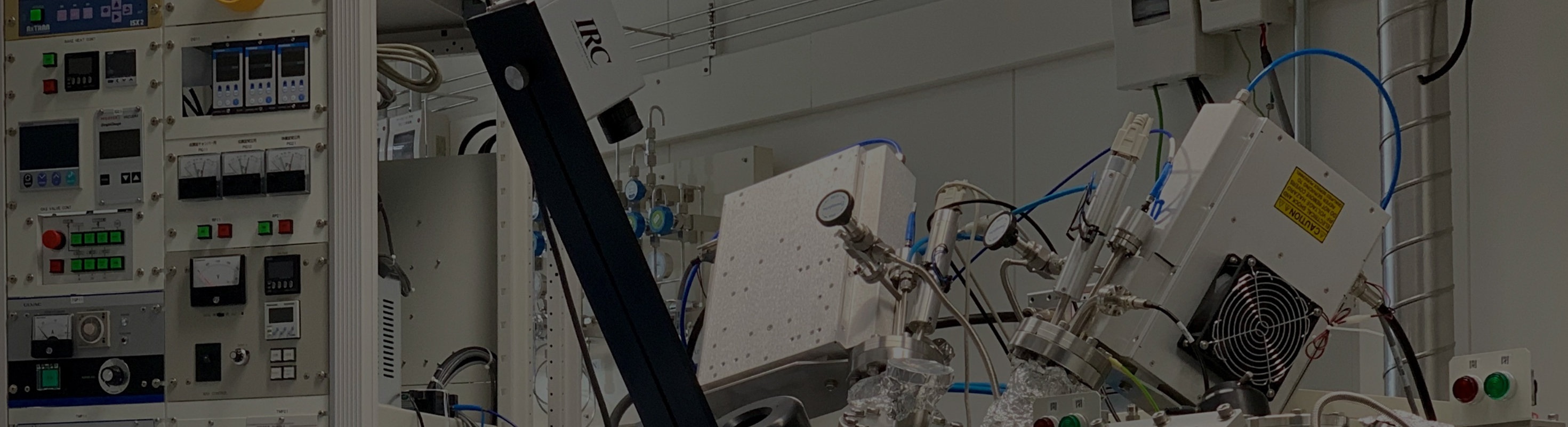

FACILITIES

Preparation of alloys & powders

We need to be able to prepare thermally stable materials as well as metastable materials in order to develop novel magnetic materials.We have not only conventional fusion facilities but also various facilities capable of low-temperature synthesis and rapid cooling synthesis.

Arc melting device

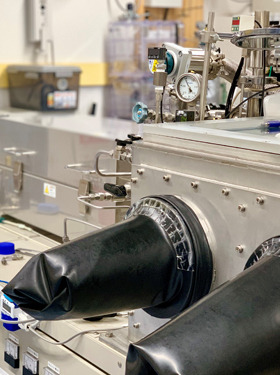

Melt-spinning device

Planetary ball-mill in

glove-box

Low-oxygen thermal

plasma system

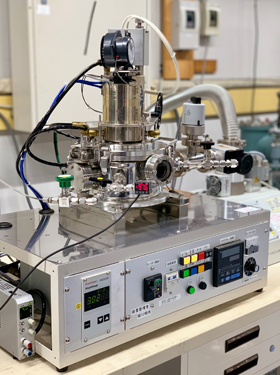

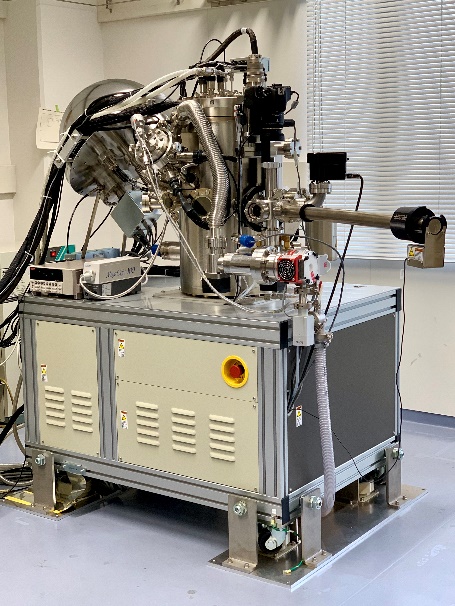

Sputtering system

combined with glove-box

Induction furnace

combined with glove-box

Swaying-rolling ball-mill

Chemical synthesis

We are developing rare-earth alloy magnets, which are usually prepared by metallurgical approaches, by chemical approaches such as reduction diffusion method.Therefore, we have various facilities for chemical syntheses.

Inorganic chemistry instruments

Centrifugal separator

Spray pyrolytic furnace

Drafter

Ovens

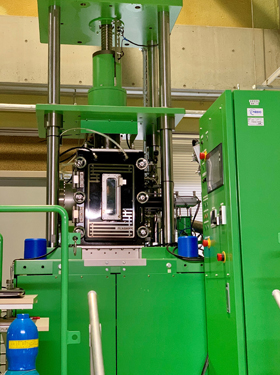

Powder metallurgy

Rare-earth magnetic materials are usually weak in oxygen, and slight exposure to oxygen significantly deteriorates their magnetic properties. In addition, metastable magnets are degraded by large thermal load. Therefore, we have facilities to produce sintered magnets without air-exposure and to sinter with low-thermal-load.

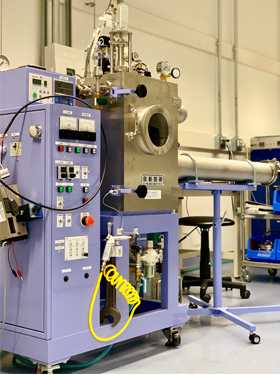

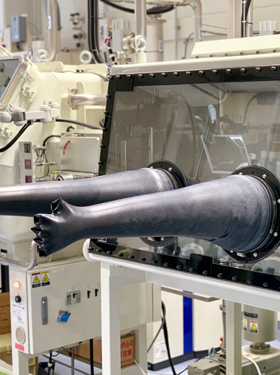

Low-oxygen powder

metallurgical apparatus

Double-action pressing

20t-class current sintering device

40t-class current sintering device

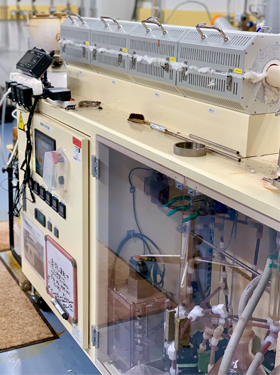

Heat treatments

Many of next generation magnets required nitriding treatments ,carbonizing treatments, and hot-deformation. These treatments need furnaces that accept ammonia, methane, and hydrogen gases.We have many kinds of particular furnaces.

NH3/H2/inert gases furnace

Ammonia nitriding

furnace combined with glove-box

Rotary furnace combined

with glove-box

High-temperature

furnace combined with glove-box

Ammonia nitriding

furnace combined with glove-box

NH3/H2/inert gases- hightemperature

universal tester

IR furnace

Processing

Rotation grinding machine

Cylindrical grinding machine

Cutter

Dicing cutter

Geometry measurement device

Material characterization

Powder density

measurement device

BET measurement device

Laser diffraction

particle measurement device

Imaging particle

measurement device

Particle crushing tester

Densimetry

High-precision balance

Microstructural characterization

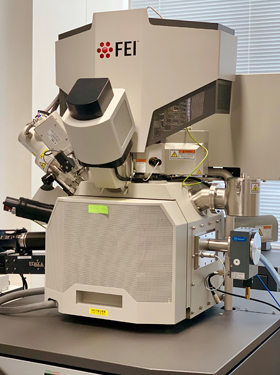

FIB/FE-SEM/EDX/EBSD

FE-SEM/EDX/EBSD/SXES

FIB

Os coater

Ion milling device

SEM/EDX

Magnetic property characterization

Pulse B-H tracer

B−H tracer

9T class PPMS/VSM

Other characterization

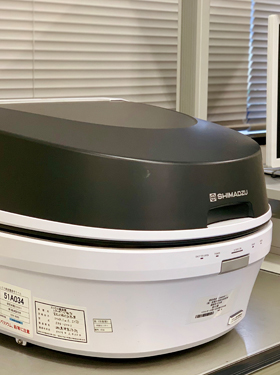

fluorescent X-ray spectrometer

X-ray diffractometer

XRF spectrometer

XPS device

TG/DTA/Q-mass

DSC in glove-box

Oxygen & nitrogen analyzer

Carbon analyzer

Hydrogen analyzer