Research Results Archive

This page provides information on our research results archive.

2024FY

[ Update: September 13, 2024 ]

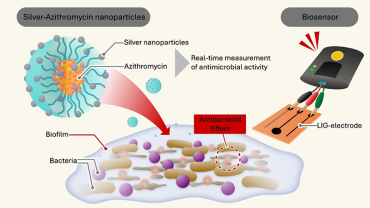

Released: September 11, 2024Tiny Warriors and Innovative Technology Are Here to Fight Back against Antibiotic-resistant Biofilms

– Researchers showed that antibiotic-infused silver nanoparticles can effectively break down biofilms while unveiling a new sensing method to assess antimicrobial activity –

From safeguarding our food supply to preventing hospital infections, the battle against antibiotic-resistant bacteria is a growing challenge. Some bacteria can form biofilms, thick aggregates of millions of individual cells surrounded by protective mucus-like substances that easily adhere to surfaces. Forming such biofilms is a critical bacterial strategy to resist treatment.

The dense, layered colonies shield bacteria from immune cells and reduce the effectiveness of antiseptics and antibiotics. “Once a biofilm forms, its structure acts as a barrier, making it extremely difficult for drugs to penetrate and kill the bacteria,” explains Dr. Chisato Takahashi, a principal investigator at the National Institute of Advanced Industrial Science and Technology (AIST). The biofilms’ extraordinary resilience has motivated researchers to seek innovative solutions beyond traditional antibiotics.

In their recently published paper in the Journal Nanoscale, a team of scientists from the Okinawa Institute of Science and Technology (OIST) and AIST have developed a novel approach to fight against treatment-resistant bacteria.

To overcome the shortcomings of conventional antibiotics, the researchers developed a unique nanoparticle that combines multiple mechanisms to kill the bacteria. "We encapsulated our silver particles inside a polymer shell of Soluplus® and infused it with azithromycin, an antibiotic. This innovative encapsulation strategy makes the nanoparticle stable and highly effective in their antimicrobial activity,” says Dr. Takahashi.

(Energy Storage Materials Group Senior Researcher, Chisato Takahashi )

2023FY

[ Update: September 15, 2023 ]

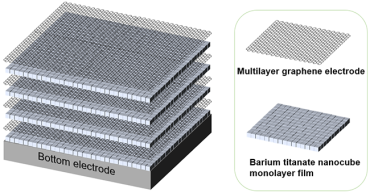

Released: September 12, 2023Paving the way for dramatically thinner multilayer ceramic capacitors

Researchers at AIST have developed a process technology for alternately stacking cubic single-crystal (nanocube) monolayers of barium titanate (BTO), a dielectric material, and multilayer graphene sheets.

The technology developed in this research makes it possible to fabricate an extremely thin multilayer structure consisting of monolayers of two-dimensionally ordered BTO nanocubes of about 20 nm in size and multilayer graphene sheets of 2–3 nm in thickness, and is expected to be a fundamental technology to realize a dramatically thin multilayer structure with alternating dielectric and electrode layers in a multilayer ceramic capacitor (MLCC).

(Energy Storage Materials Group Researcher, ITASAKA Hiroki, Chief Senior Researcher, LIU Zheng, Senior Researcher, MIMURA Ken-ichi, Group Leader, HAMAMOTO Koichi, )

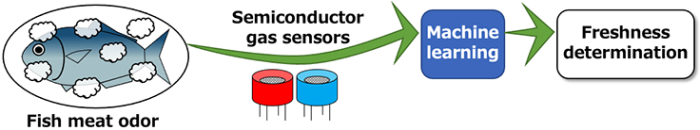

Developed Sensing Technology to Determine Freshness of Fish Meats from Their Odors

Easy, non-destructive determination of freshness

Researchers at AIST, in collaboration with the Hokkaido Industrial Technology Center of Hakodate Regional Industrial Promotion Organization, have developed a sensing technology to determine the freshness of fish meat from its odor, using yellowtail as a model.

Raw fish, such as sushi and sashimi, is becoming increasingly popular around the world, and chilled fresh marine products are exported from Japan to overseas. Overseas, there are few professionals with thorough knowledge of raw fish consumption, and it is difficult to distinguish between marine products for raw consumption and those for cooked use, so most of the marine products are currently handled is by Japanese-affiliated stores. In order to expand the export volume of Japanese marine products, it is necessary to have objective quality assurance indicators and their measurement method. K-value has been proposed as a freshness index for fresh marine products. However, the derivation K-values requires to sample fish meat; and it takes a certain amount of time even if knowledge workers perform the chemical measurements to derive K-values. Therefore, there was a need to develop a new sensing technology to determine freshness of marine products easily.

AIST has developed a new sensing technology for odor determination. This is a non-destructive test that does not require to sample fish meat because it targets fish odors. AIST, in collaboration with the Hokkaido Industrial Technology Center, analyzed the odor of each freshness level of fish meat, and based on the results, prepared simulated freshness indicator gases. Using the measurement results to the indicator gases as training data, machine learning was used to determine freshness of an actual fish meat based on its odor.

(Electroceramics Group Senior Researcher,Toshio Itoh,Researcher, CHOI Pil Gyu,Group Leader,MASUDA Yoshitake)

2022FY

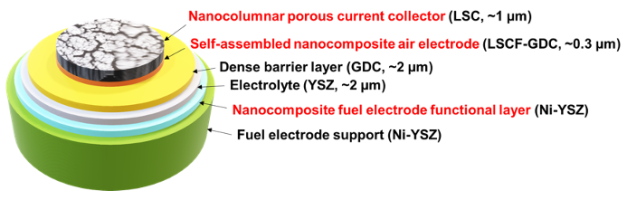

Development of High-performance Electrode for Nanostructure-controlled Solid Oxide Fuel Cell (SOFC)

Achievement of world top-level power generation performance

Researchers in AIST developed a nanostructure-controlled high-performance air electrode in a study performed under the Advanced Technology Consortium for Solid State Energy Conversion (ASEC), which is engaged in strategic joint research with multiple companies. In addition, an SOFC single cell equipped with the developed electrode exhibited world top-level power generation performance.

In addition to the self-assembled nanocomposite air electrode fabricated using the pulsed laser deposition (PLD) method, the SOFC single cell is equipped with a nanocolumnar porous current collector and nanocomposite fuel electrode functional layer, which were developed to fully demonstrate the performance of the air electrode. The resulting single cell achieved the world top-level power density of 4.5 W/cm2 or more at 700 °C. This achievement will contribute to the reduction of the SOFC cell stack size and manufacturing costs.

Details of the results were published in the open access journal Nature Communications (electronic version) on June 25, 2021.

(Solid State Ionics Materials Group Chief Senior Researcher, Hiroyuki Shimada)

2021FY

[ posted in AIST Research Highlights, Nov.26.2021 ]

Released: June 15, 2020Solid Oxide Fuel Cell Drone Capable of Long-term Flight

A drone was equipped with an LPG-powered fuel cell, enabling to fly for an hour or more

A high-power, lightweight, internal reforming solid oxide fuel cell (SOFC)

that operates on liquefied propane gas (LPG) was developed for drones with

large power load fluctuation. A drone that uses this SOFC as a power source

to enable long-term flight and work was demonstrated for the first time

in the world.

This system uses internal reforming SOFC technology developed by AIST,

and can use commercially available LPG cartridges as fuel gas.

(Solid State Ionics Materials Group Senior Researcher, Hirofumi SUMI)