Research Activity

Thermochemical hydrogen compressor using metal hydride

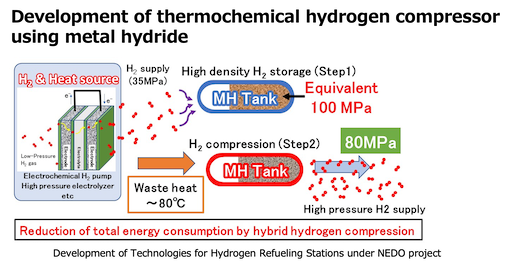

For wide spread of hydrogen refueling stations, low-cost and high-efficient hydrogen compressors are required. The thermochemical hydrogen compressors using metal hydride, the so-called MH compressors, have the potential to address both aspects because they are thermally-driven. We proposed the combined system of two types of compressors. The first compressor, a high-pressure water electrolyzer or an electrochemical hydrogen pump, provides both medium pressure hydrogen (40 MPa) and waste heat to run the second compressor, an MH compressor. Under NEDO "Development of Technologies for Hydrogen Refueling Stations" project, we have developed metal hydrides which absorb hydrogen between 20-35 MPa at 30℃ and desorb above 80 MPa when heated to 80℃.

Schematic image of thermochemical hydrogen compressor Demonstration of hydrogen compression

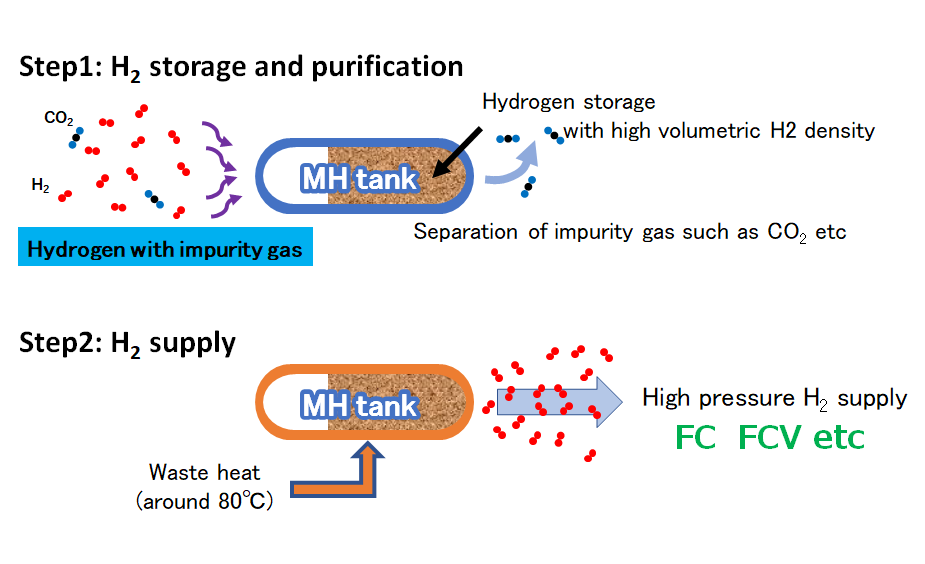

Hydrogen purification based on the selective reaction of metal hydride

When hydrogen is produced, it is necessary to purify it because it often contains impurity gases. In contact with gas mixtures, hydrogen storage materials have the interesting feature of selectively capturing and absorbing hydrogen. The desorbed hydrogen is then of very high purity. Because of the reversibility of this process, it is possible to apply it for a hydrogen purification device. There is a possibility for degradation of hydrogen absorption properties caused by the gaseous impurities. Therefore, we have been developing hydrogen storage materials with a resistance against impurity gas. Especially, we focus on the purification of gas mixtures of hydrogen and CO2 under NEDO project, “International joint research for supply technology of high-pressure and purity of hydrogen by chemical compressor using formic acid”.

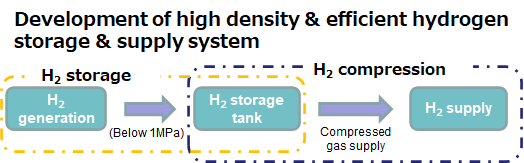

Hydrogen storage and supply for Power to gas system

Recently renewable energy widely increases and spreads. They are often produced intermittently, which leads to a fluctuation of the available energy over time (hour, day, season). One of the solutions is “Power to gas (P2G)” technology. It consists in converting the excess electricity to hydrogen by using electrolyzers. This hydrogen is stored as energy and then, when the energy is needed, it is supplied to a fuel cell to generate electricity. P2G technology consists of hydrogen generation, storage, and utilization. For hydrogen storage, hydrogen storage alloys, mainly LaNi5 based alloys, have been applied because of high volumetric hydrogen density and low operation pressure (< 1 MPa). However, development of low cost hydrogen storage materials is needed for future widely spread large-scale use. For this purpose, we have been developing Ti-Fe based hydrogen storage materials under NEDO project. The hydrogen storage tank containing the developed hydrogen storage materials was installed in demonstration facility in Yamanashi prefecture.

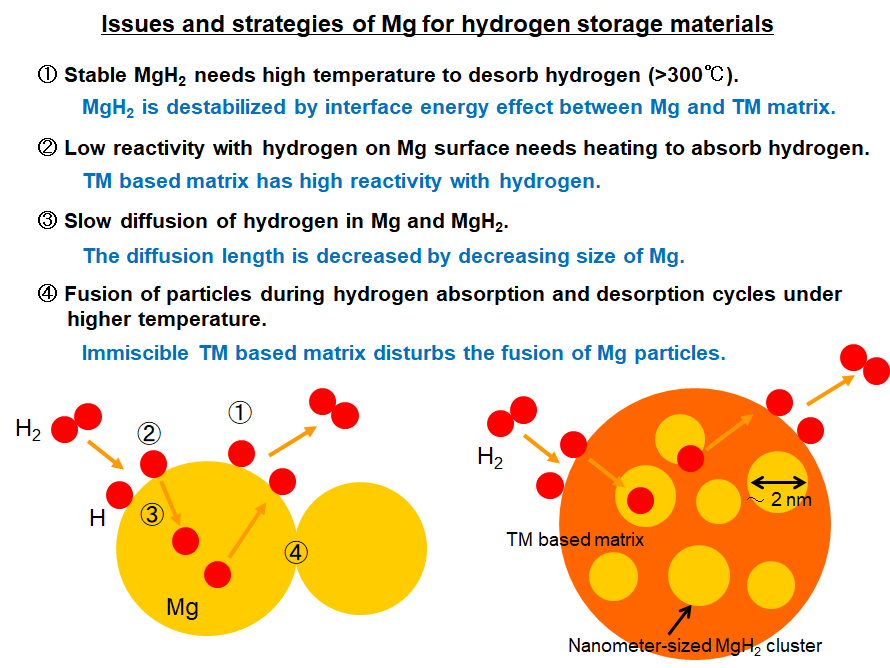

Development of novel hydrogen storage materials with specific nanometer-sized structure for high capacity and low material costs

Cost of hydrogen storage materials is the bottleneck for the large-scale development of hydrogen storage and supply system. Mg is one of the most attractive materials to tackle this issue. However, its reaction temperature with hydrogen is too high for practical application and must be lowered. We are developing high capacity and low-cost materials by combining Mg with immiscible transition metals (TM). We are studying this R&D topic under domestic and international collaborations.

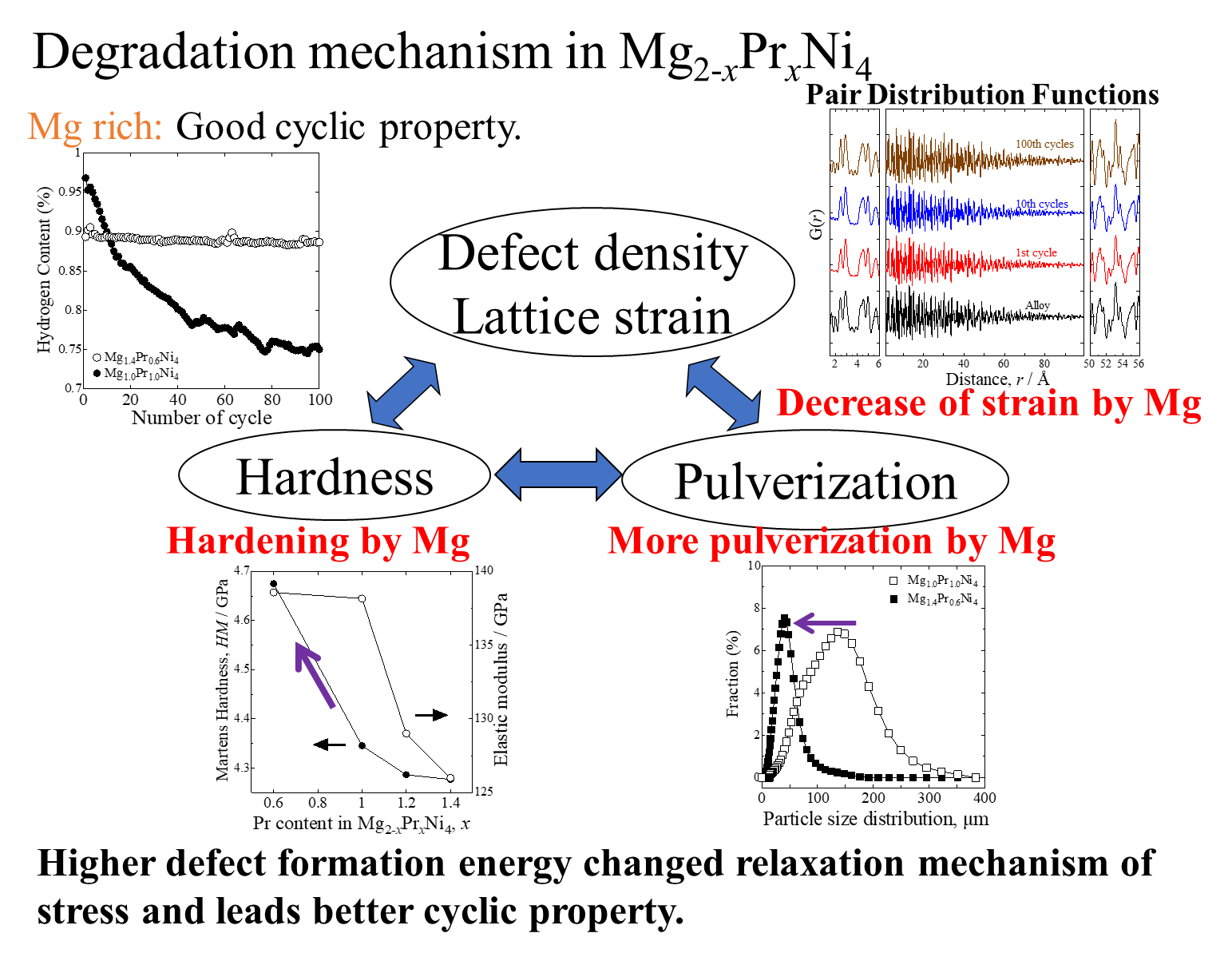

Basic research for metal hydride with advanced analysis technique

Depending on the application, the requirements for hydrogen storage materials are different. In all cases, however, improvement of hydrogen storage capacity and durability is essential. These properties are related to hydrogen occupation site, and distortion of lattice caused by lattice defect. In order to understand the hydrogen occupation site and origin of the degradation, we have used in-situ X-ray diffraction, NMR, synchrotron X-ray and neutron total scatterings. We are also focusing on developing of new setup for in-situ measurement of these techniques.