Equipments

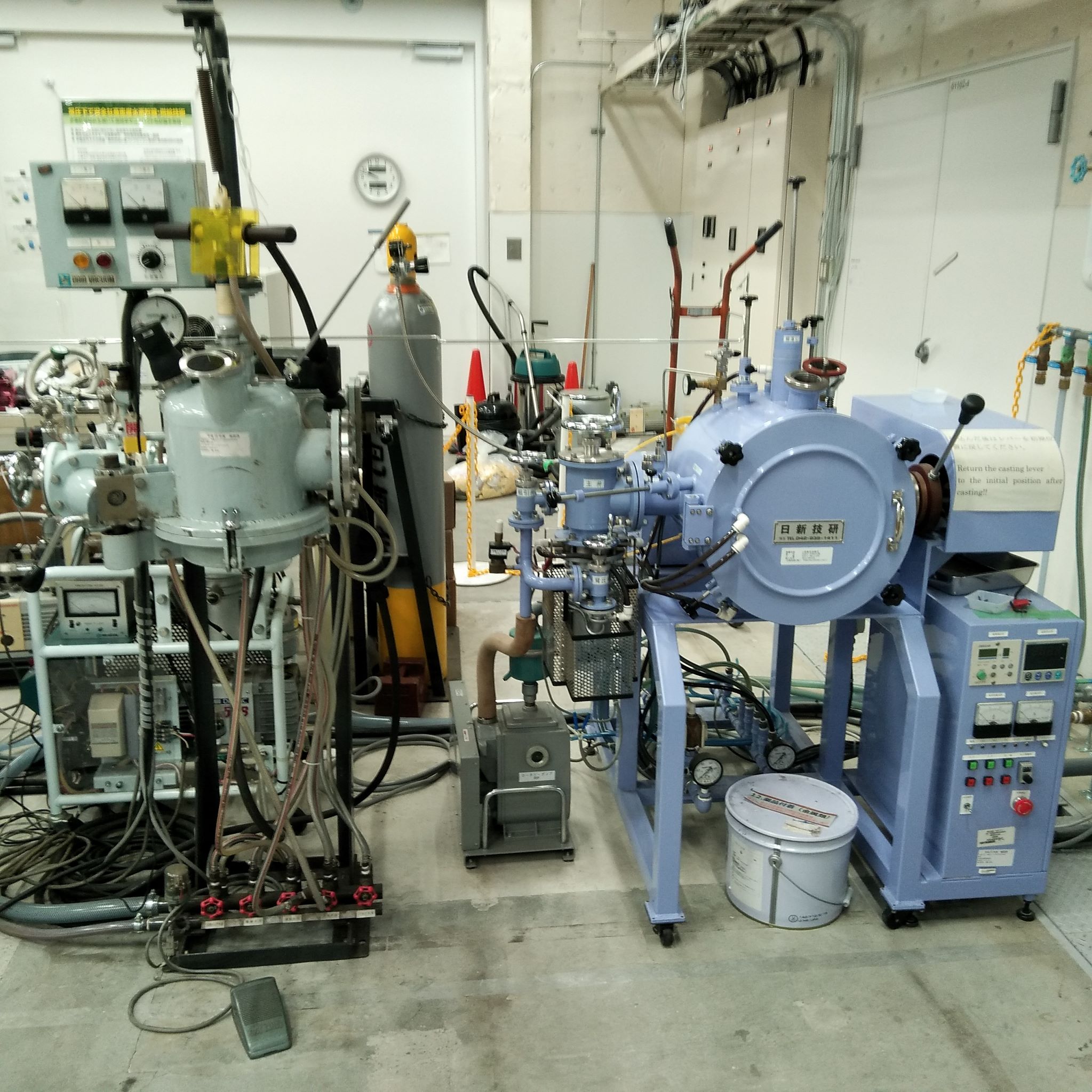

Synthesis methods

We synthesize the hydrogen storage materials by melting (with an arc melting furnace or a high frequency induction melting furnace), ball milling or sintering. We have several different furnaces for an annealing under Ar atmosphere or in vacuum with a maximum temperature of 1500℃. Our pressing devices allow sintering under Ar atmosphere or in vacuum in a wide temperature range.

(Left) Arc melting furnace Planetary ball mill High Energy

vibration ball mill

(Right) Induction furnace

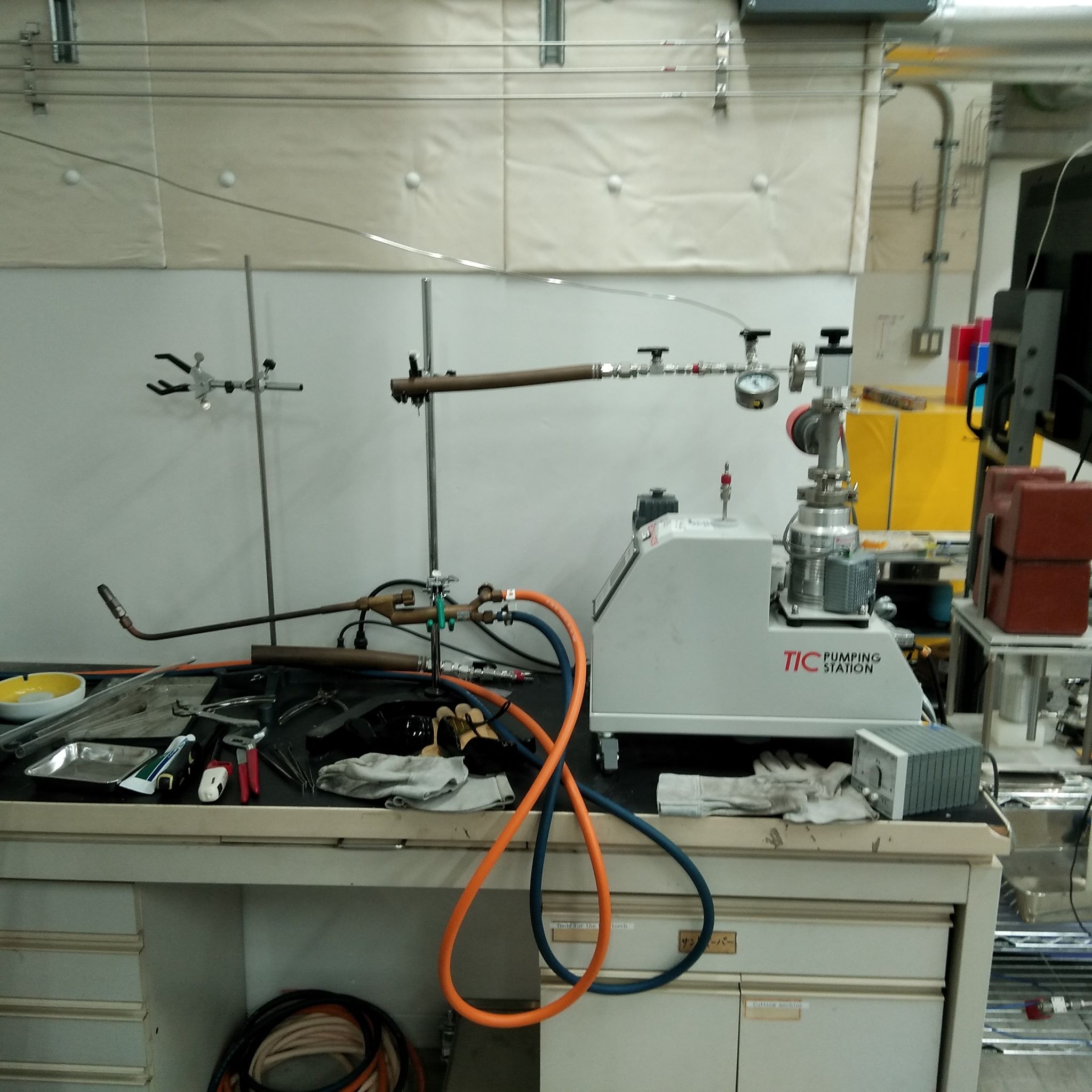

Quartz tube encapsulation Annealing furnaces Pressing device

(1500℃, Vacuum or Argon) (Argon・Vacuum・Heating)

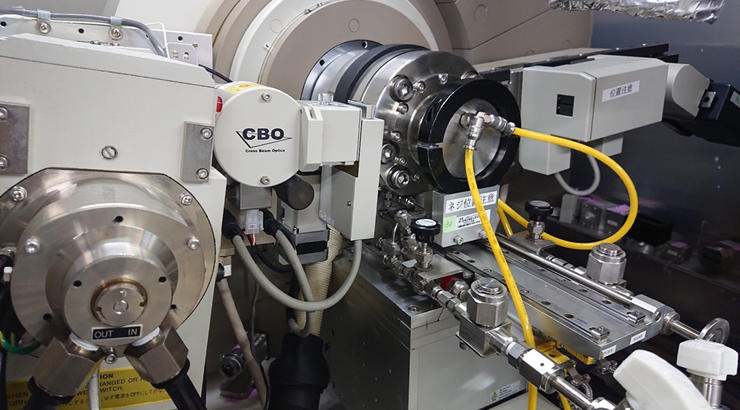

Structural and chemical characterization

Material characterization is carried out by X-ray diffraction (XRD), Scanning electron microscope with energy dispersion X-ray spectrometer (SEM-EDX) etc. The crystal structure change induced by hydrogenation can be observed in-situ in the pressure range to 5 or 10 MPa and from -10℃ to 190℃ thanks to an XRD equipped with high pressure chamber. In order to identify the local environment around H, Nuclear Magnetic Resonance (NMR) is performed.

X-ray diffraction SEM-EDX NMR

Raman Spectroscope In-situ Ⅹ-ray diffraction

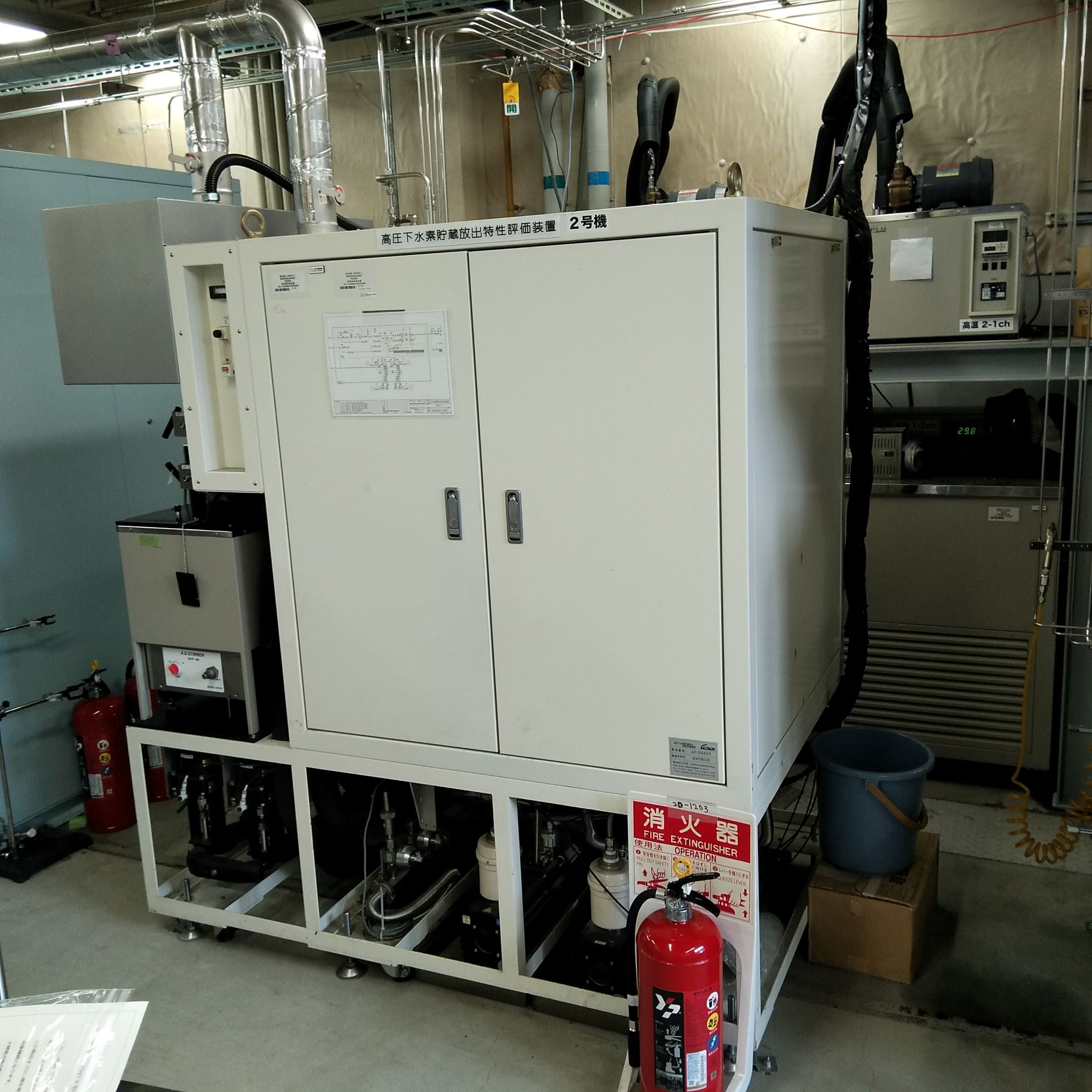

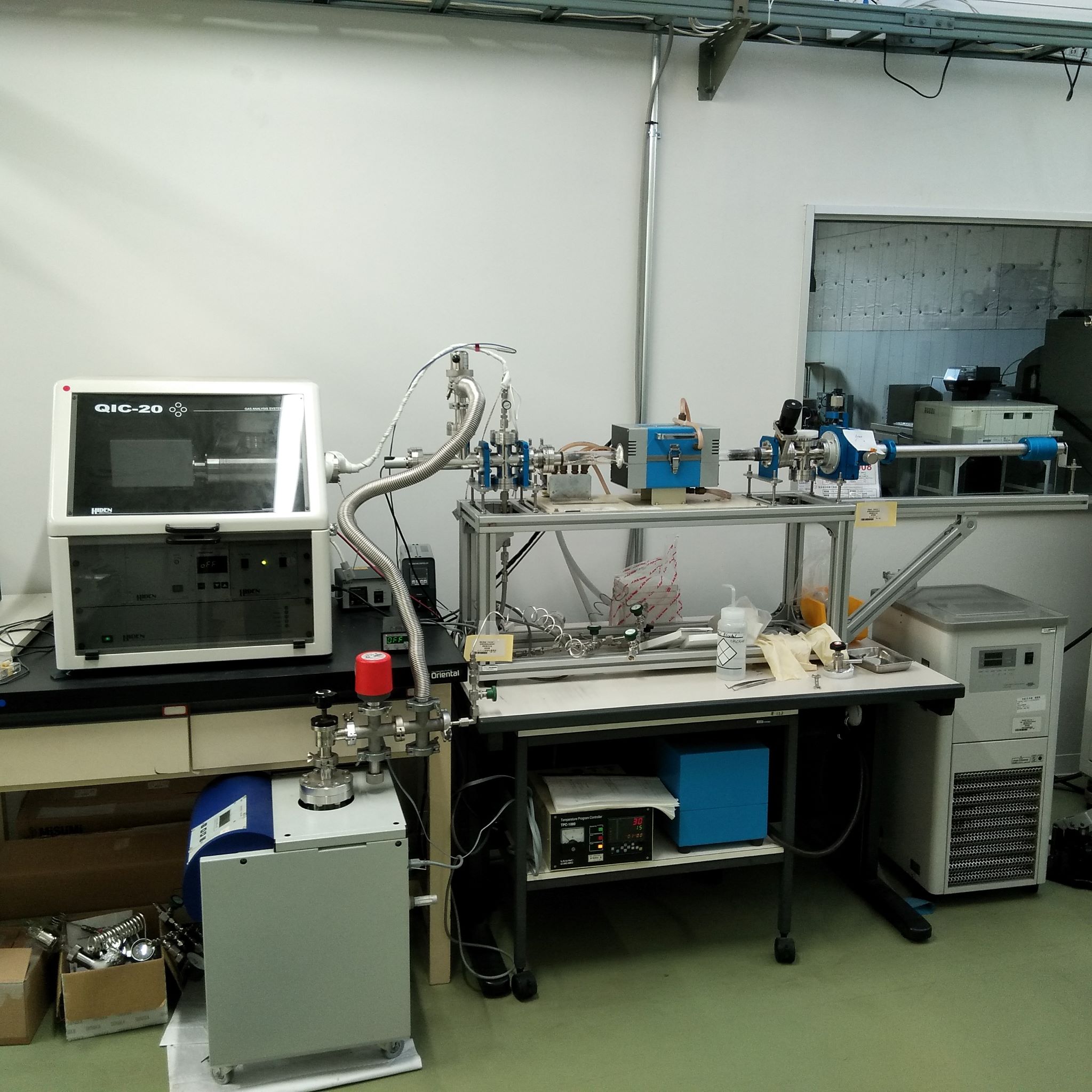

Hydrogen storage properties

Hydrogen storage properties are evaluated by various techniques. Pressure-Composition Isotherms are measured in the temperature range from -90℃ to 400℃. They can be evaluated up to 100 MPa. Differential Scanning Calorimetry (DSC) under hydrogen pressure provides the information of phase transformation upon hydrogenation and dehydrogenation. Hydrogen desorption temperature is evaluated by Thermogravimetry-Differential Thermal Analysis (TG-DTA) and Thermal Desorption Spectroscopy (TDS).

Pressure-Composition Isotherm measurements

PCT up to 1 MPa PCT up to 10 MPa PCT up to 40 MPa

PCT up to 40 MPa PCT up to 100 MPa

(Left) Pressure-DSC Thermal desorption spectroscope Hydrogen analyzer

(Right) TG-DTA

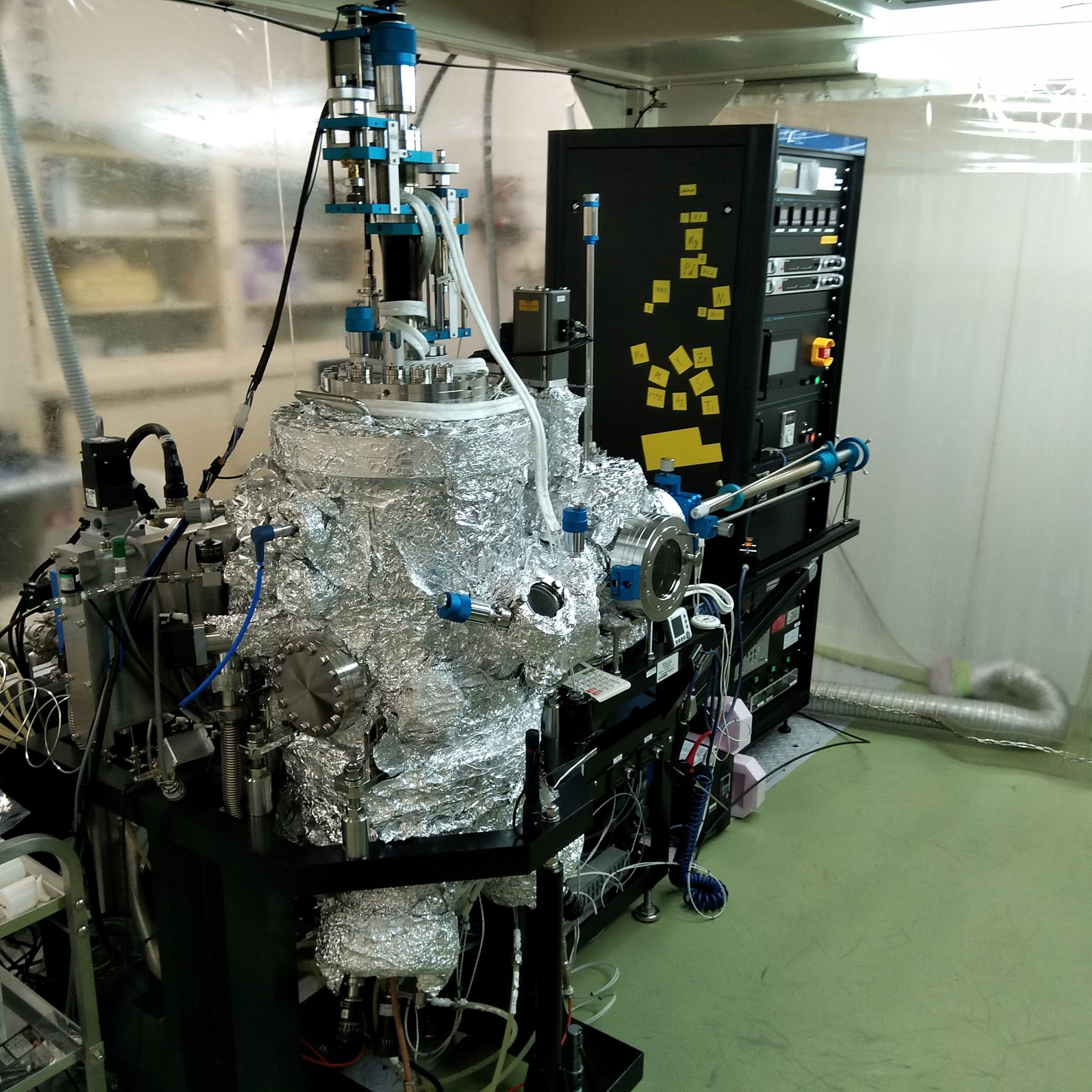

Characterization for Thin film

A thin film of hydrogen storage material is expected to be used in various industrial applications. Magnetron sputtering equipment allows the synthesis of thin films with the co-sputtering of three elemental targets. The device is designed in such a way that sample transfer without exposure to air is possible. Hydrogenation properties can be evaluated by using the change in optical property of thin film upon hydrogenation.

Magnetron sputtering Hydrogenography Thickness measurement

Others

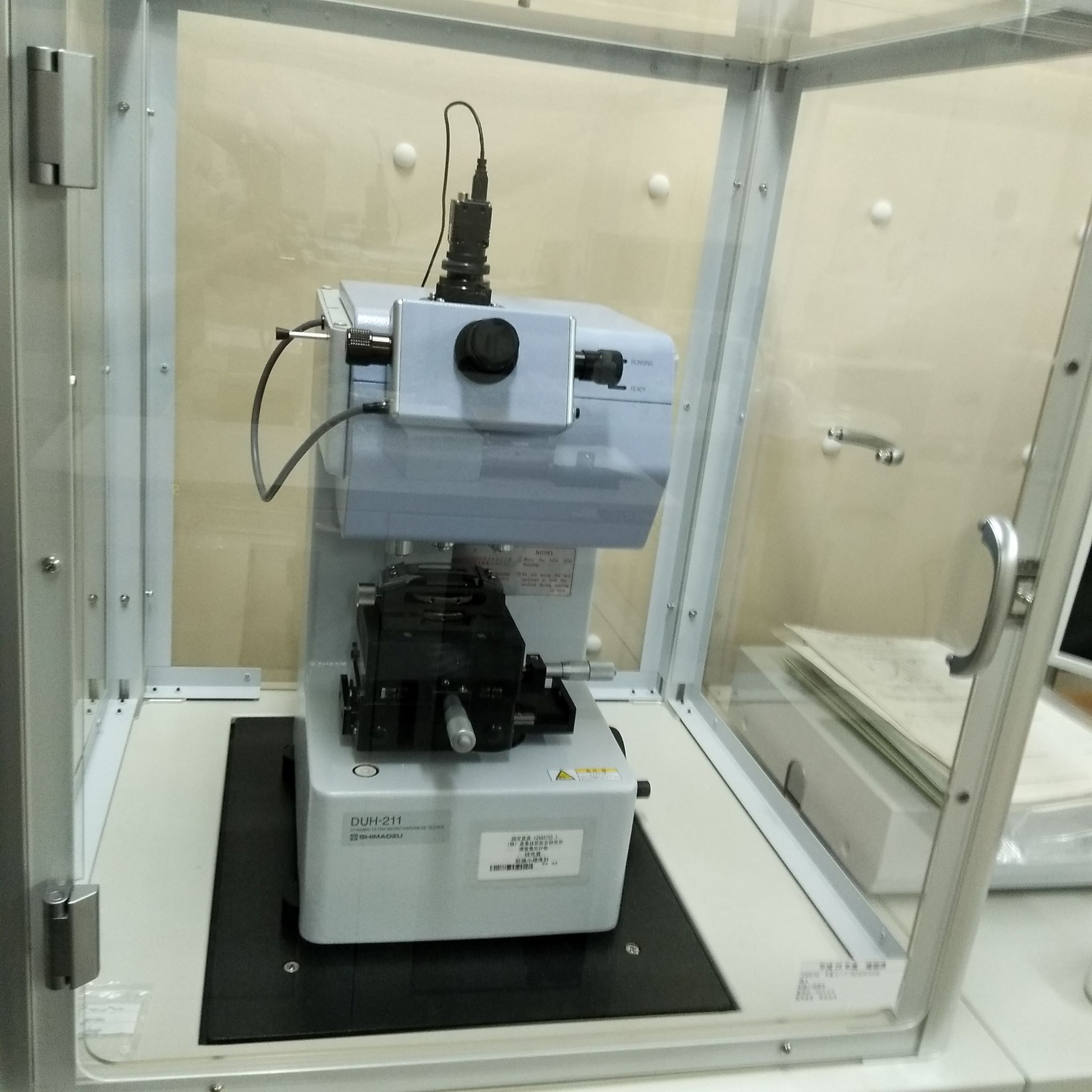

Change of particle size distribution is measured before and after pulverization upon hydrogenation. Various hardness testers are also installed.

Particle size analyzer Glove box