Remanufacturing Research Group

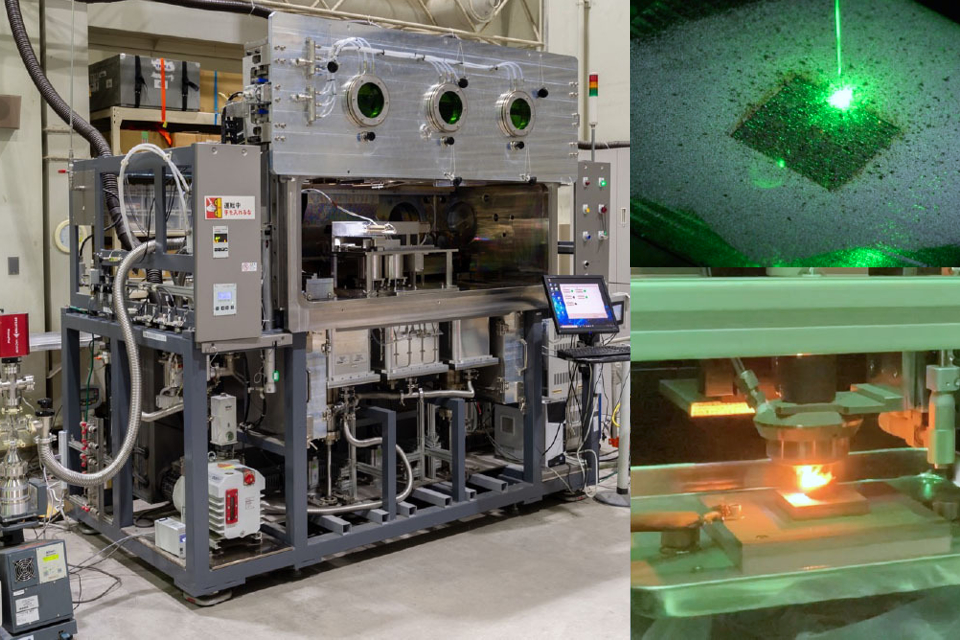

Research and development of metal additive manufacturing to realize the next generation of flexible smart manufacturing

About

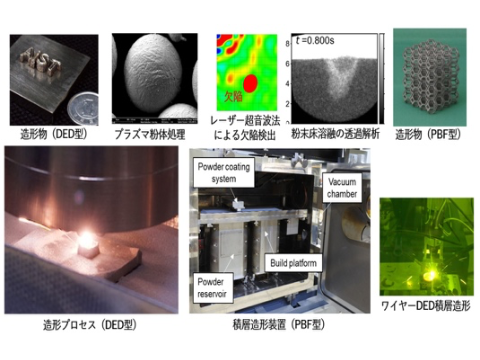

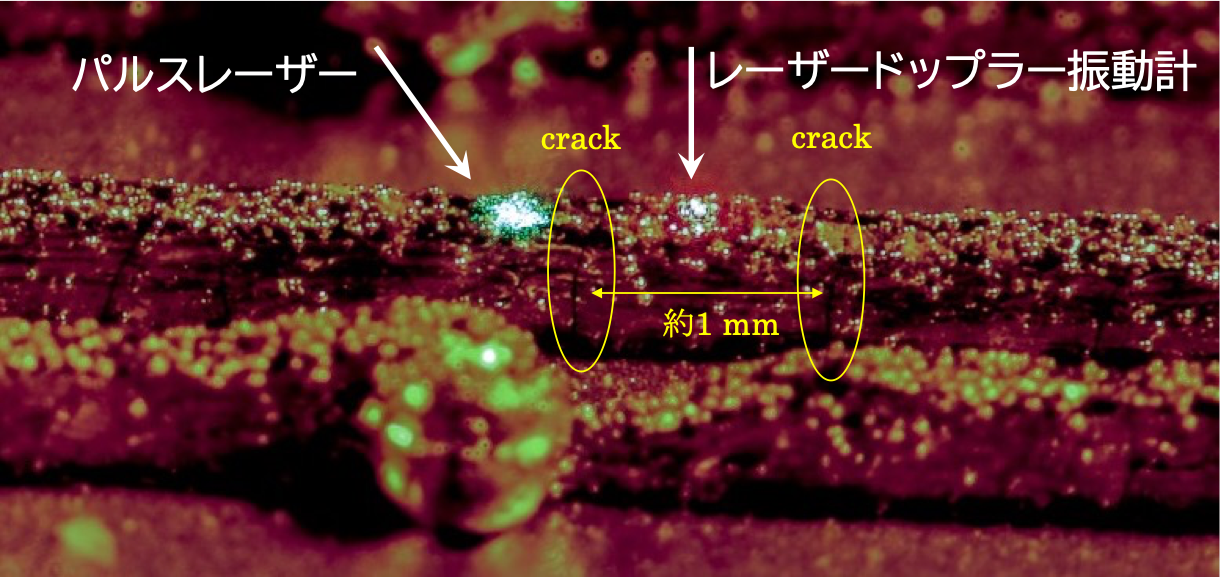

We are promoting research and development of novel repair technologies toward leveraging the diversification of remanufacturing process, covering the amplification of composition and crystal structure formation control of objects manufactured through additive manufacturing process, enhancing the quality of the metal powder particles, and advancing the in-situ evaluation technology through the use of ultrasonic measurement.

Keywords

remanufacturing, additive manufacturing, laser powder bed fusion, crystallinity control, plasma treatment, metal powder, ultrasonic measurement

Subjects

-

1.Metal Additive Manufacturing

We are developing innovative laser scanning strategies to facilitate non-columnar, isotropic grain structure formation on the deposited layer matching the grain characteristics of the polycrystal base object without the dependency on auxiliary nucleant addition, tailored for enhancing additive remanufacturing applications.

-

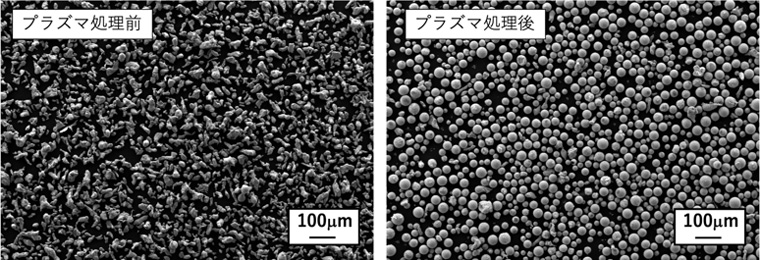

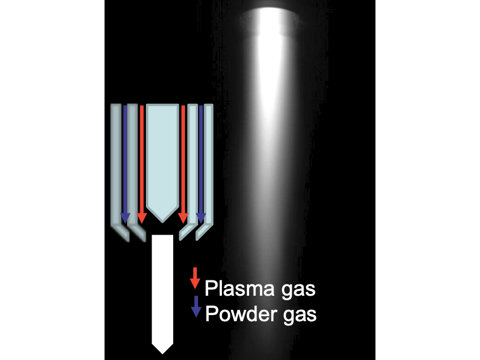

2.Plasma Treatment

We are conducting research and development on plasma processes toward elevating the spheroidization and functionalization of metal powders, aimed at expanding the range of material options for metal additive manufacturing and establishing post-process powder reutilization technology.

-

3.Ultrasonic Measurement

Our research focuses on the implementation of nondestructive ultrasonic measurement technology to clarify complex processing phenomena in additive manufacturing process. We are also developing inspection technology based on laser ultrasonic waves addressing the nondestructive evaluation for objects manufactured through the laser powder bed fusion method (PBF-LB/M).

Themes

-

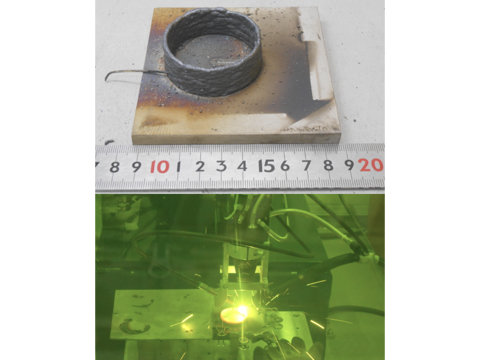

Advanced microstructure control technique in additive remanufacturing

In this research, we are realizing advanced scanning vectors control in IN718 superalloys to realize the microstructure in Image 1. The scanning method enable isotropic crystal orientation to be generated, along with forming non-columnar grain structure and grain size refinement. Currently, we are further assessing further technique in order for the grain characteristics of the deposited layers to closely resemble the characteristics of the base objects in terms of grain size to control the mechanical properties in all directions, along with further precise control in the microstructure generation in the interface area.

View more

In this research, we are realizing advanced scanning vectors control in IN718 superalloys to realize the microstructure in Image 1. The scanning method enable isotropic crystal orientation to be generated, along with forming non-columnar grain structure and grain size refinement. Currently, we are further assessing further technique in order for the grain characteristics of the deposited layers to closely resemble the characteristics of the base objects in terms of grain size to control the mechanical properties in all directions, along with further precise control in the microstructure generation in the interface area.

View more

-

The study for quality optimization of metal powders for additive manufacturing using plasma technology.

So far, raw metal powders for additive manufacturing are generally expensive and the usable kinds are limited. To overcome these issues, our research group is making an intense study on plasma treatment technologies for metal powders.

View more

So far, raw metal powders for additive manufacturing are generally expensive and the usable kinds are limited. To overcome these issues, our research group is making an intense study on plasma treatment technologies for metal powders.

View more