Surface Interaction Design

Learning from the structure functions in the natural world,

Development of high-performance components by combining structure and material characteristics

About

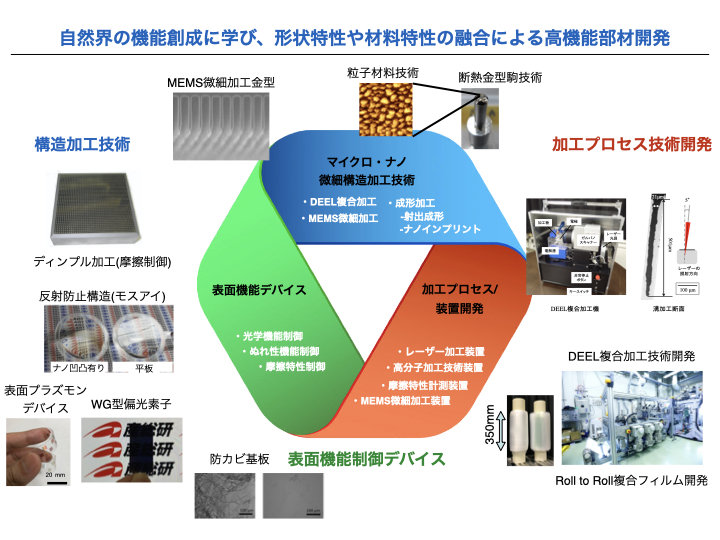

In the natural, there are many things that express characteristic functions such as sub-wavelength optics, wettability control, and friction control by combining the characteristics of both structure and material.

We imitate the functions and shapes of these natural worlds, research and development to realize highly functional parts that cannot be achieved only by material properties and stcutre characteristics, and the creation of new physical phenomena. We are developing process technology to convert scientific phenomena into forms that can be used in industry.

Focusing on surface property control, we are conducting research activities to contribute to improving the properties of various functional parts.

Points

- 1Development of high-performance components that fuse strcutre, material properties

- 2Control functions such as sub wavelength optics, wettability and friction properties

- 3Development of process technology for industrial use of the unique creative functions of nature

Feature

In the manufacturing technology research division(AMRI), new microfabrication process technology that integrates different field technologies such as ultra-precision metal processing technology, laser processing technology and MEMS semiconductor microfabrication technology, ultraprecision molding technology such as injection molding method and nanoimprint method, inorganic thin film We are developing high-performance materials with controlled surface functions such as sub wavelength optics, wettability, and friction properties by fusing material technology, organic material technology, and polymer material technology.

In addition, through the research and development activities of a team that brings together these wide-ranging areas of specialized technology, we aim to create original high-performance components that cannot be replaced by others. In addition, we are conducting consistent research activities to bridge the developed research results through social implementation.

Result

-

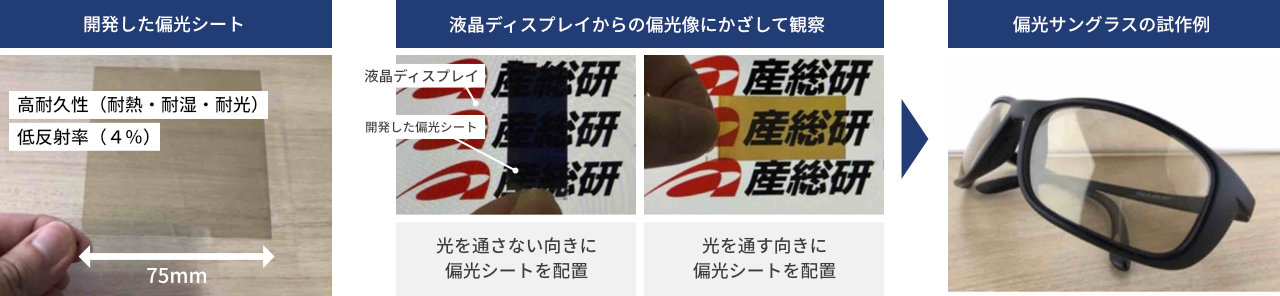

1.Light ControlDevelopment of wire grid polarizers

Aiming to expand into fields where application has been difficult, we have developed low-reflectivity and highly durable wire-grid polarizer sheets that are difficult to achieve with conventional methods by successfully combining nanoimprinting and printing technologies. Instead of vacuum deposition, the structure is formed by silver nanoparticle ink, and through appropriate sintering, a degree of polarization of higher than 99 % and a reflectance of lower than 5 % are achieved.

Links (external publications, patents, related news, etc.)

- Highly Durable Polarizing Sheet with Low Reflectance Realized by Printing Technology

- https://www.aist.go.jp/aist_j/press_release/pr2019/pr20190701/pr20190701.html

- Development of ultra-high definition and thick film printing technology using capillary force of microstructure

- https://www.aist.go.jp/aist_j/press_release/pr2016/pr20160912/pr20160912.html

-

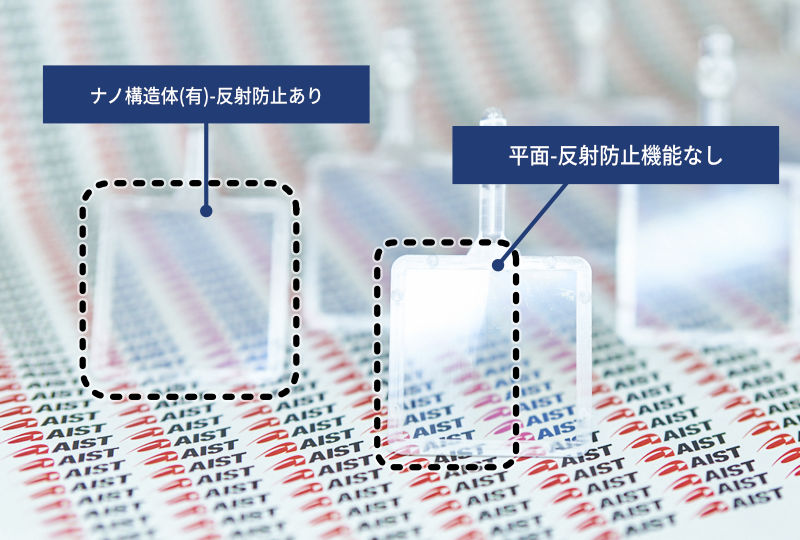

2.Light ControlDevelopment of antireflection optical element by nanostrcuture

By combining material alloy technology and thin film vacuum technology, we have realized nanostructures on curved molds such as lens.

We are also developing technology to realize anti-reflection function only by moldging technologies using injection molding and nanoimprinting. Using this technology, we are developing optical components that combine wide-angle, low-reflectivity and anti-fogging properties that can reduce reflections up to 60 degrees, the world's highest level.

Links (external publications, patents, related news, etc.)

- Developed an optical member that combines the world's highest level of wide-angle low reflectivity and anti-fogging properties

- https://www.aist.go.jp/aist_j/press_release/pr2020/pr20201124/pr20201124.html

- Development of mass production technology for lenses with anti-reflection function using nanoparticles

- https://www.aist.go.jp/aist_j/press_release/pr2007/pr20070423/pr20070423.html

-

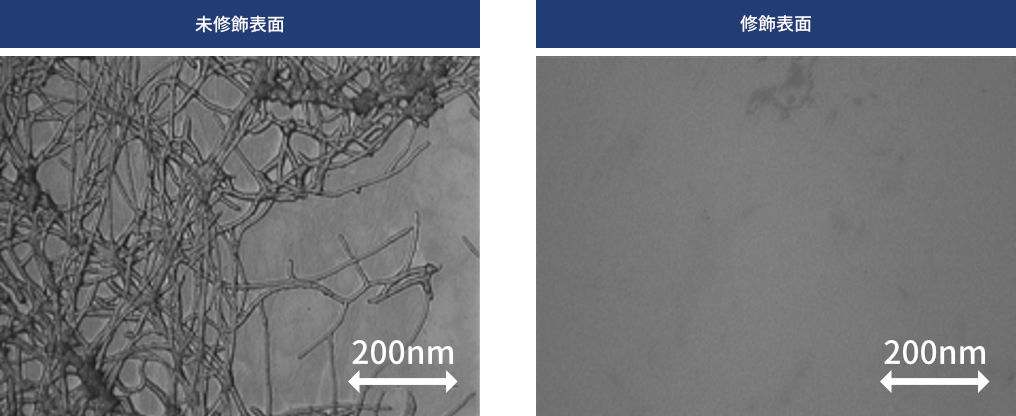

3.Friction ControlDevelopment of antifungal technology

There is a growing social interest in and demand for technology that prevents fungal adhesion from contaminating living environments, food, medical equipment, etc., and from infecting animals and plants.

We have developed a coating technology that controls the chemical properties of the surface to suppress the adhesion of fungi to the surface and to easily remove fungi growing on metals, ceramics, and glass by washing with water.Rubbing test results of Cladosporium sp.

-

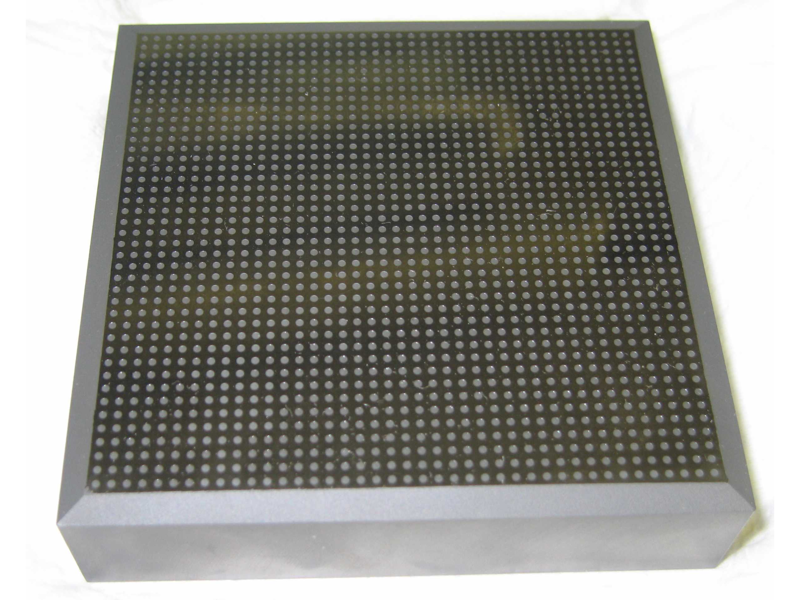

4.Friction ControlDevelopment of friction control by surface texturing

The fact has been known that it is possible to control the water repellent, optical properties, and thermal properties by forming microstructure on the surfac. Fathermore it is also possible to control the tribological properties.

By processing dimples and grooves on the friction surface, we can reduce friction and improve motion characteristics in the fluid lubrication and mixed lubrication regimes.

-

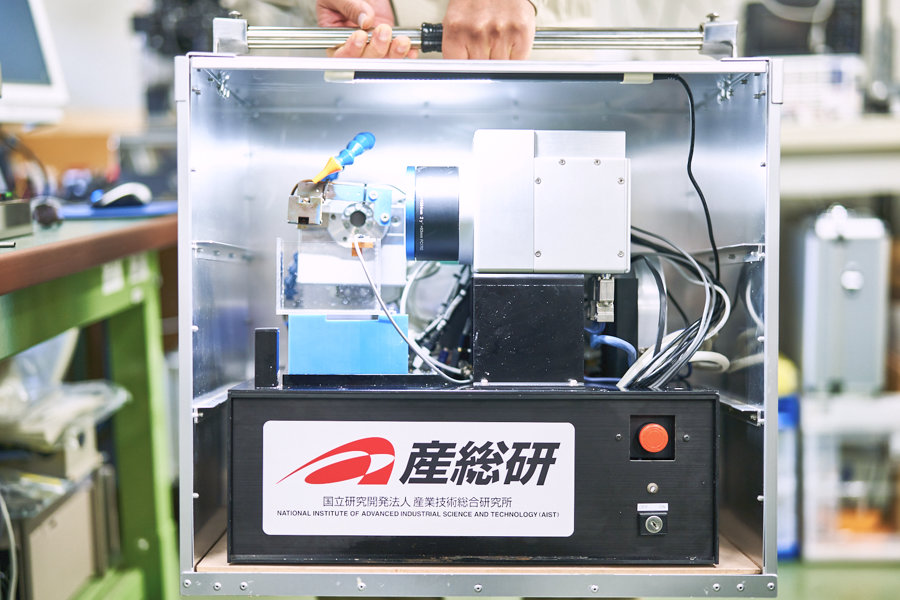

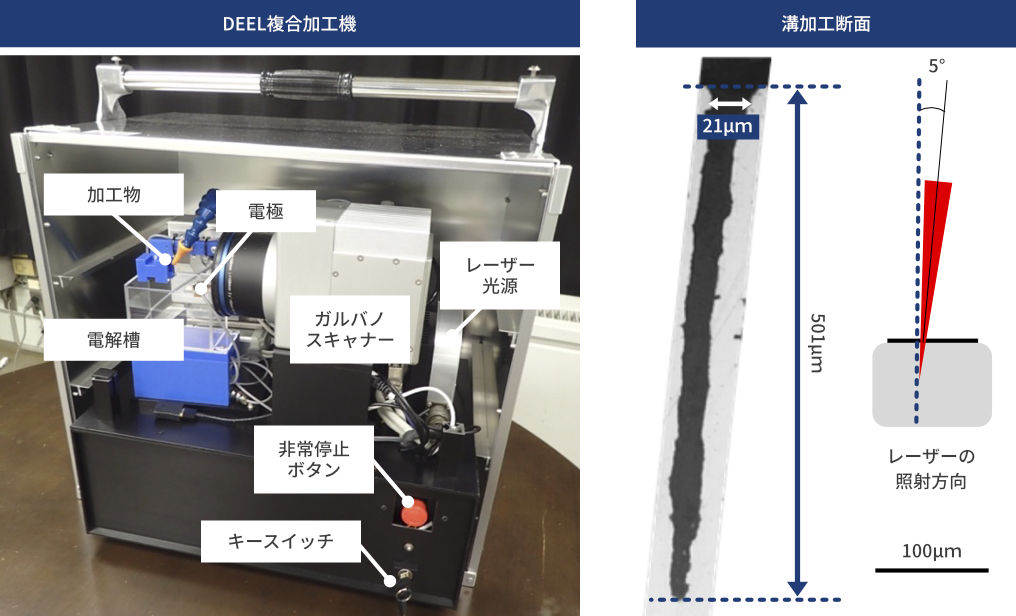

5.Complex MachiningDEEL(Deep Electrochemical Etching with Laser assistance)complex machining

We are creating complex machining technologies that efficiently apply multiple processing principles to achieve dramatic improvements in functionality and effectiveness compared to conventional processing technologies, and we are also developing devices with unconventional functions using these processing technologies. The DEEL complex machining machine enables narrow and deep groove metal processing, which is difficult to do with conventional machines, without affecting the processing of debris and other materials.

Links (external publications, patents, related news, etc.)

- Realizing High-quality Precision Processing with Ultra-compact Machinetool by Combining Processing Technologies

- https://www.aist.go.jp/aist_j/press_release/pr2018/pr20180531/pr20180531.html

- Development of a Machining System Capable of Machining a Metal Tube the Size of a Human Hair into a Complex Shape

- https://www.aist.go.jp/aist_j/press_release/pr2009/pr20090326/pr20090326.html

-

6.Wettability ControlHydrophilicity and water repellency control by wettability control by nanostructure

Using Wenzel's theory, which can increase the wettability effect according to the surface roughness of the concave-convex structure, we have realized hydrophilicity and water repellency control of plastic resin.

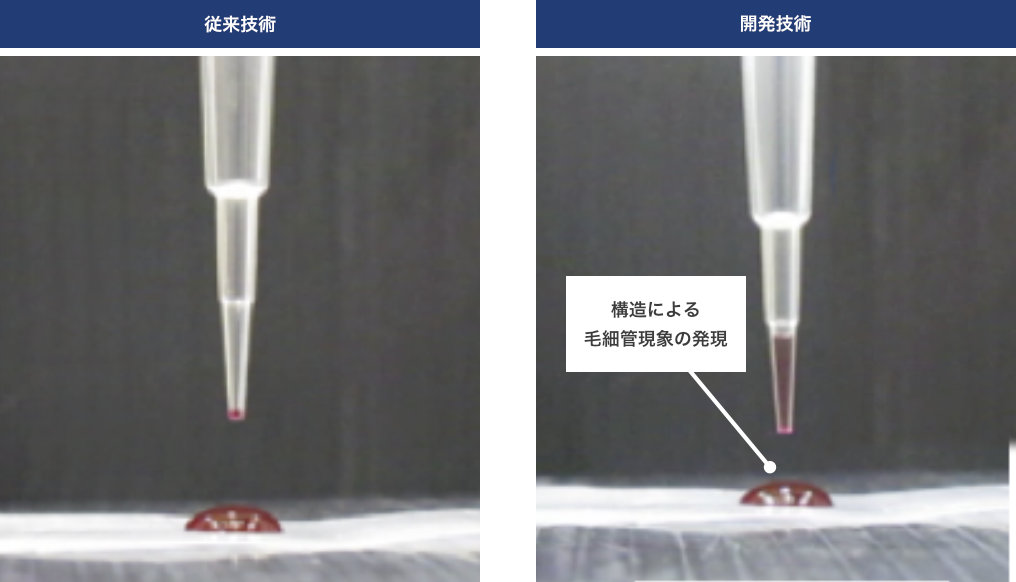

With only the nano-imprinting technology of nanostructures, it is possible to change a resin substrate that repels water into a resin that can form a water film by adding a structure. When pipettes are manufactured using this technology, capillary force can be expressed by the structure.

Links (external publications, patents, related news, etc.)

- The water-repellent plastic surface becomes hydrophilic just by molding

- https://www.aist.go.jp/aist_j/press_release/pr2009/pr20091013/pr20091013.html

-

7.Heterogeneous bonding by nanostructureDeformation-less bonding technology of bio-chip by adhesion control of nano-structure

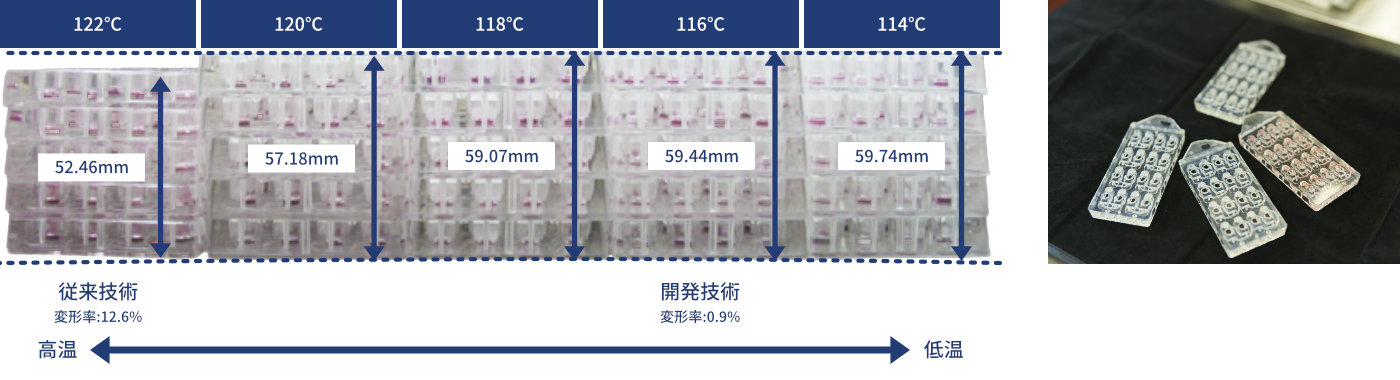

Using nanostructure micromolding technology obtained from the development of antireflection nanostructures, using the anchoring effect of nanostructures, we are developing bonding technology for bonding resin substrates such as microchannel chips by thermal welding at low temperatures. I am developing.

By using this technology, deformation during joining can be reduced to 1/10 or less compared to conventional plastic resin welding joining, and ultra-precision joining of microstructures can be achieved.

-

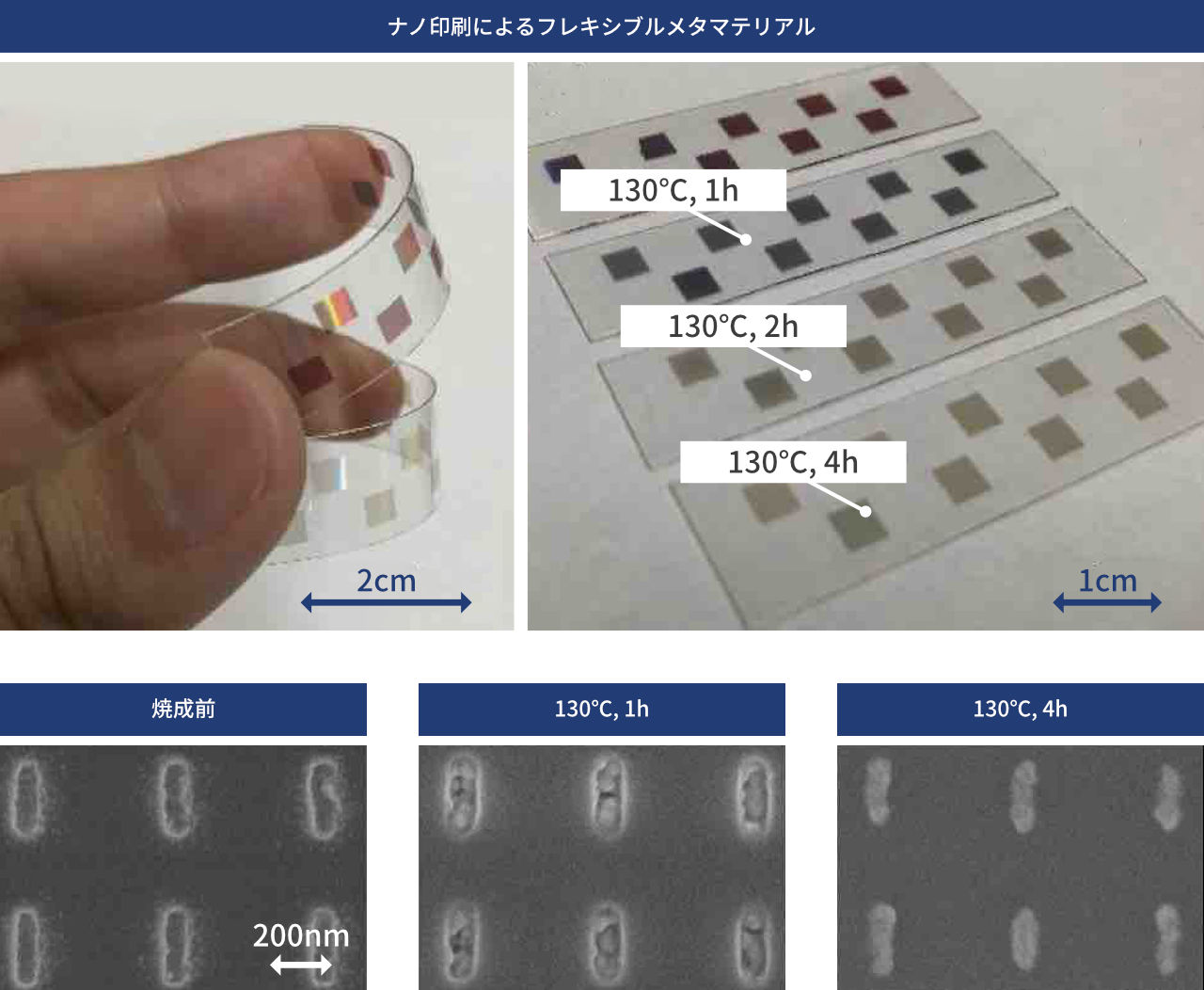

8.Light ControlResearch on Printed Metamaterials

We study metamaterials formed by printing nanoparticle ink. Not only is it easy to produce metamaterials, but also by utilizing the fact that the shape of the nanoparticles that make up the metamaterial structure changes depending on the firing conditions, optical characteristics different from those of metamaterials produced by the film deposition process can be obtained.