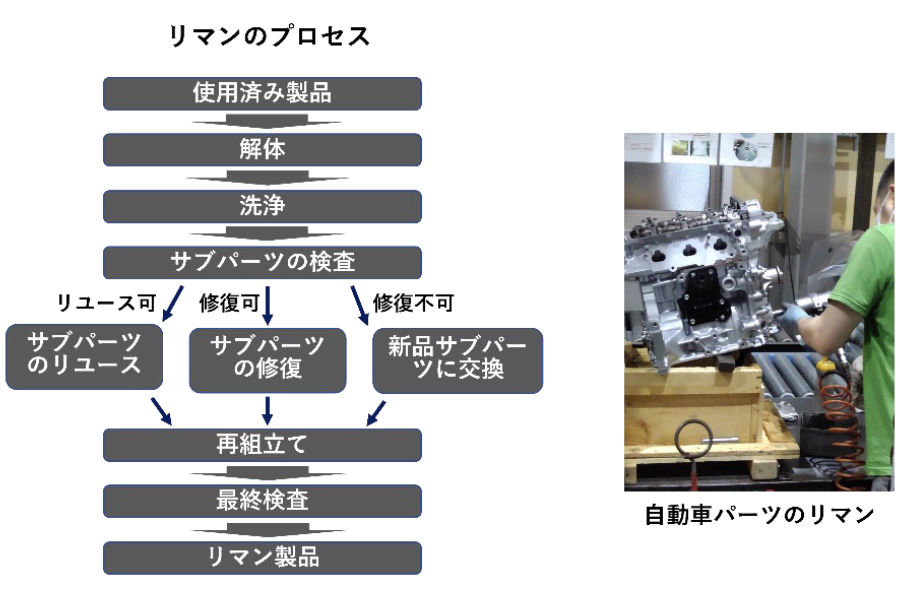

Remanufacturing

Enebling the circular economy through developing technologies that enable to use once-manufactured-goods as long as possible

About

All goods someday finish their roles and lives. From users' points of view, just buying new goods in replace of end-of-life goods is sufficient. However, the process of waste management and new product manufacturing requires energy, material resources, and yields CO2 emissions, which have burdens on global environment. We can reduce the burden on environment through regenerating product functions, using components longer, and minimizing end-of-life goods. Remanufacturing is a technology that enables to use once-manufactured-goods as long as possible, and supports realizing the circular economy and reducing the environmental loads of our society. We lead R&D of advanced manufacturing to realize a society where remanufacturing is common and seen everwhere.

Feature

The Advanced Manufacturing Research Institute (AMRI) promotes research and development (R&D) of remanufacturing. The process technologies needed for remanufacturing include the advanced techniques of disassembly, inspection, non-destructive testing, restoration, repairing, machining, and reassembly, The system technologies such as design for remanufacturing (DfReman), production system, informatoin platform, environmental impact assessment, and social acceptance analysis of/for remanufacturing are also necessary. We are working on R&D of remanufacturing based on our competency in research in mechanical engineering, machining, digital manufacturing, and life cycle engineering.

Technology

Inspection and measurement

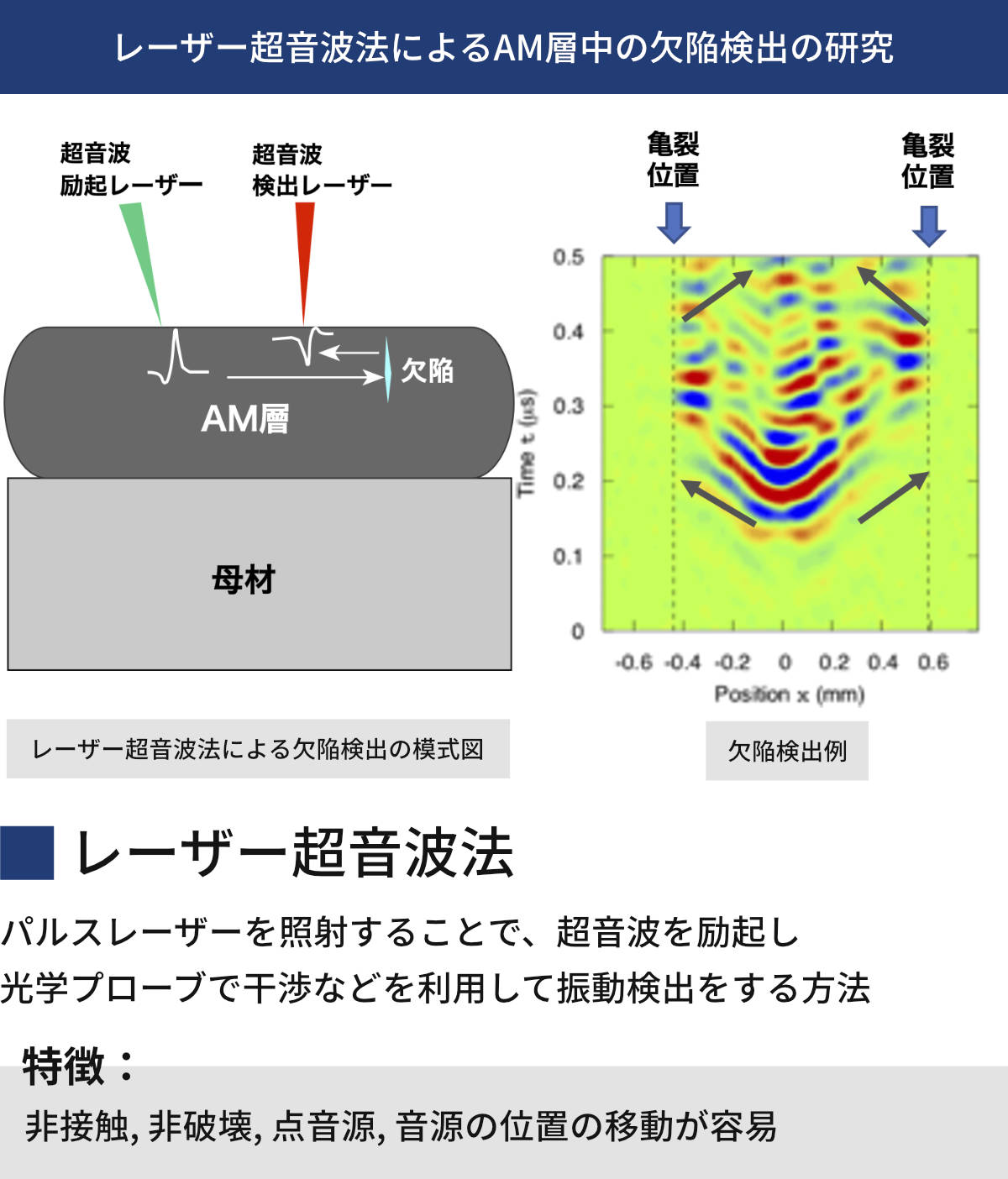

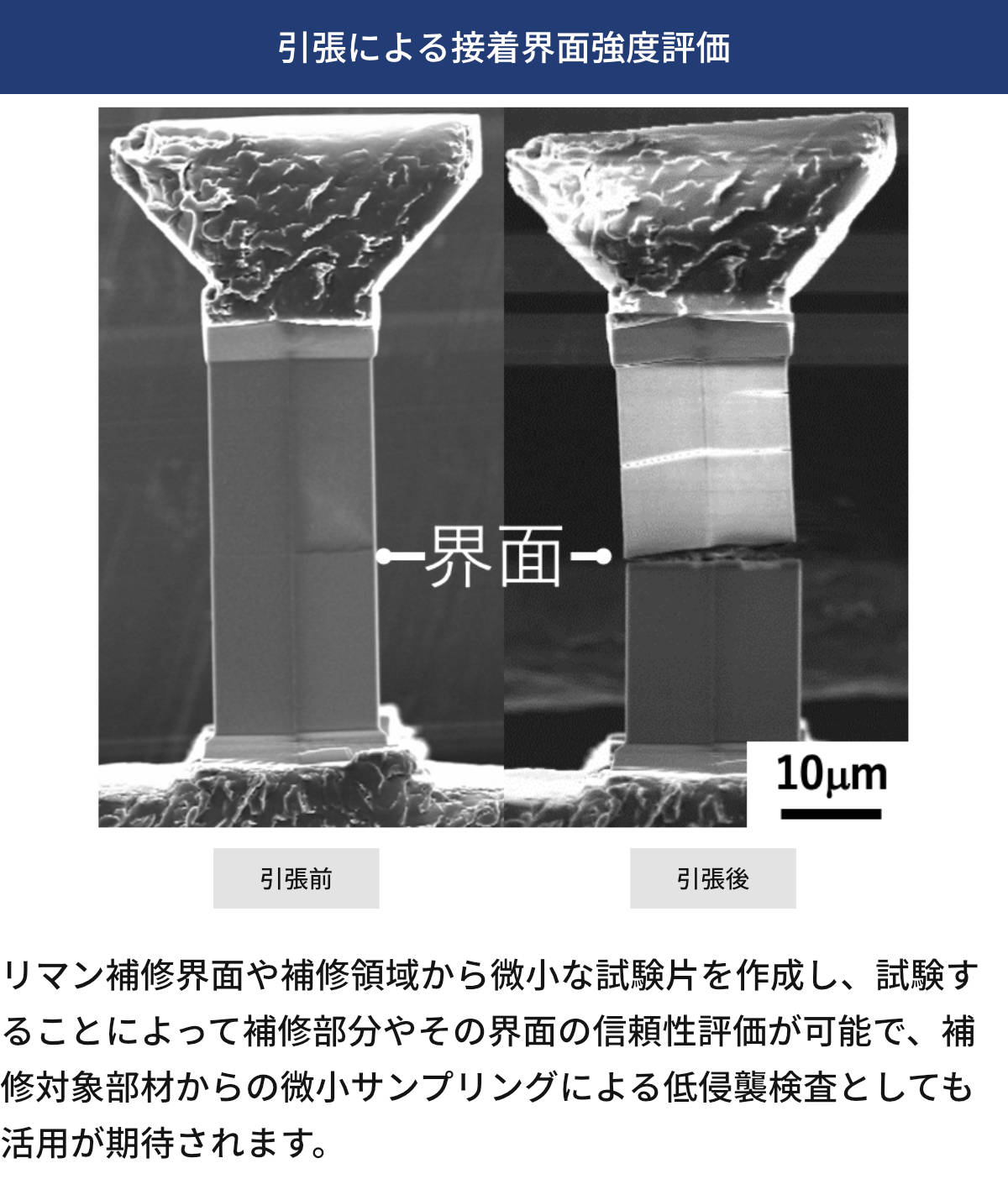

Technologies of inspection, measurement, and reliability assessment and remaining lifetime estimation are the keys to improving the producitivy, reliability, economy, and resource efficiency of remanufacturing. The condition of used products (cores) varies, and it is essential to identyfy the state and reliability of cores and remanufactured products precisely. We are working on R&D of laser ultrasonic non-destructive inspection, micro measurement, X-ray fluoroscopic observation, tribological property evaluation, bearing damage diagnosis, thin-film peeling diagnosis, and so on.

- In-process inspection of internal cracks

- Micro measurement

- X-ray fluoroscopic observation

- Tribological property evaluation

- Bearing damage diagnosis

- Thin-film peeling diagnosis

Restoration, repairing, machining, and processing

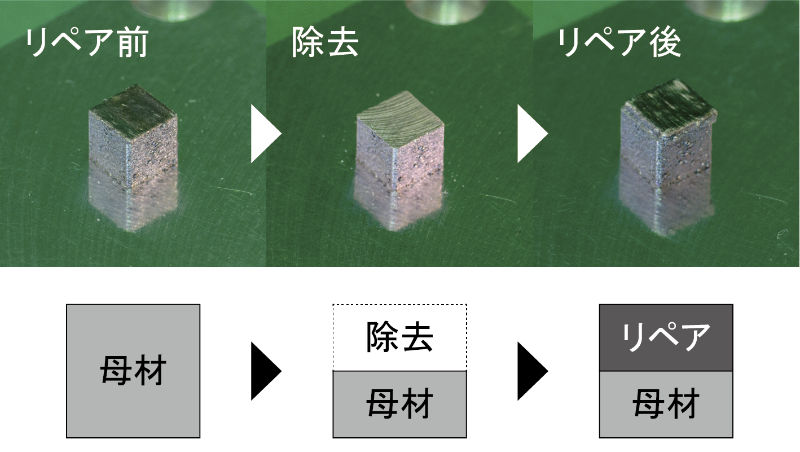

The process of restoration of damaged or deteriorated parts is a core process of remanufacturing. The advent of additive manufacturing (AM), a synonym for 3D printing, has opened new opportunities for remanufacturing. AM opens the ways to digitalization, automation, and decentralization of remanufacturing. We work on R&D of techniques of restoration using powder bed fusion (PBF) AM, and spray coating.

- PBF AM repair

- Spray coating, Hybrid aerosol deposition (HAD), Cold spray

- Wire DED

- AM powder plasma processing

- Photo-assisted metal organic deposition (MOD)

- On-demand repair/upgrade

- Device design for remanufacturing

- Adhesive bonding and separation

The damaged region is sliced off, and then the region is restored by PBF AM

Cold spray, one of the AM technologies, is characterized by its ability to perform high-speed additive manufacturing. We are working on applying cold spray technique to restoration in remanufacturing.

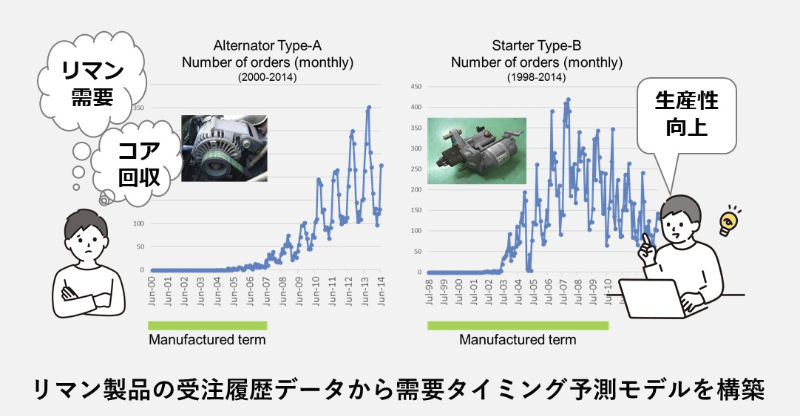

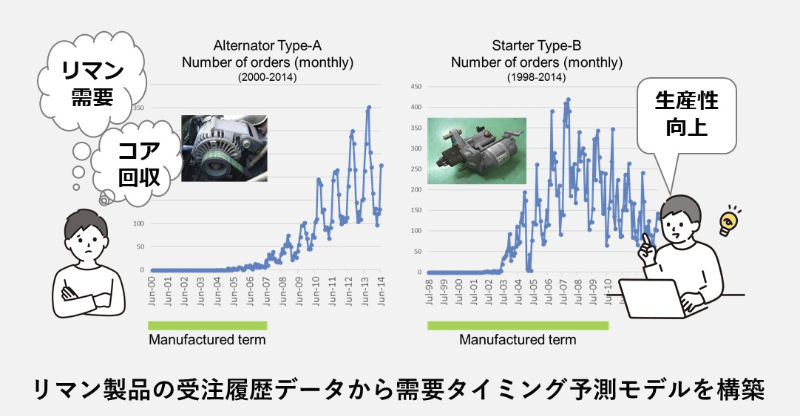

Social system, standardization

We work on research in design for remanufacturing (DfReman), production systems and information platform for remanufacturing. The conditions of cores (used-products collected for remanufacturing) vary significantly, and thus the techniques of digital transformation (DX) and artificial intellingece (AI) are indispensable in the remanufacturing processes. We also work on life cycle assessment (LCA) of remanufacturing, resource efficiency indicators development, social acceptance analysis of remanufacturing, and overseas benchmarking of remanufacturing.

- Operations management and demand forecasting of remanufacturing

- Product resource efficiency indicator

- Analysis of demand-side perception of remanufacturing

- Remanufacturing case studies

- Life cycle assessment (LCA)

We work on analyses of product condition data to improve the productivity and reliability of remanufacturing in collaboration with industrial partners.

リマンを考慮した製品資源効率指標の開発を推進している。リマンの効果の可視化と企業の意思決定を支援する。