Additive Manufacturing

About

Additive manufacturing (AM) is a new manufacturing technology that is expected to create new product value, such as multi-product/variable-volume production, weight reduction, and higher functionality. We are engaged in comprehensive research and development, mainly in AM for the manufacture of metal components, including materials, equipment, processing, evaluation, and exploring new opportunities for AM products created from these series of element technologies.

Points

- 1Focusing on AM for metallic materials, conduct research and development with an awareness of the process chain such as powder processing, equipment, processing technology, and evaluation technology.

- 2Contributing to the creation of new product value and the application of AM to the manufacturing industry through the development of AM technologies.

Keywords

Additive manufacturing(AM), Plasma treatment for metal powder, Powder bed fusion(PBF), Directed energy deposition(DED), Wire DED, High-speed 3D sand printing for metal casting molds, Composite process of additive manufacturing and rolling

Feature

We are developing various types of AM technologies, including the development of high-speed 3D sand printing for metal casting molds, and laser DED technology for alloying materials and microfabrication. We also develop AM powder modification technology, processing technology, and evaluation technology, and conduct comprehensive research and development activities in a wide range of technological areas from materials to finished products. Through national projects and joint research with companies, we are building a value chain system from downstream to upstream with the cooperation of industry, government, and academia, and are also engaged in activities such as the promotion and activation of the industrialization of AM technology.

Result

-

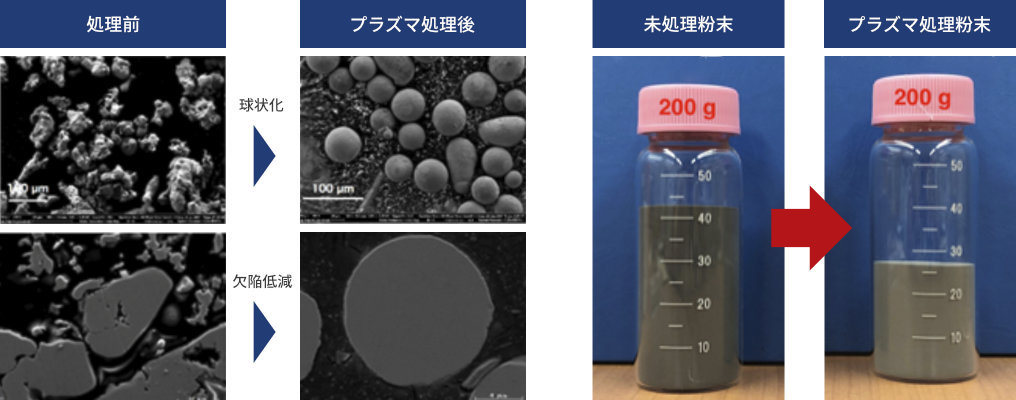

1.Plasma Ttreatment Technology for an Improvement of Powder Properties.

We are making an intense study of a powder treatment technology using a plasma technology, being aimed at diversifying the kind of metal powders for additive manufacturing (AM), reducing the cost, and getting the good reusability. With our plasma technology, we have successfully treated various powders with poor adaptability to AM such as water-atomized powders, crushing powders and granulated powders, giving them high fluidity, high packed density, and few defects, accordingly we have succeeded in getting good powders with suitable properties for AM.

Figure: The effects on the plasma treatment (left) on powder spherizing and defect reduction and (right) on an increase of packing density demonstrated by the volume shrink.

-

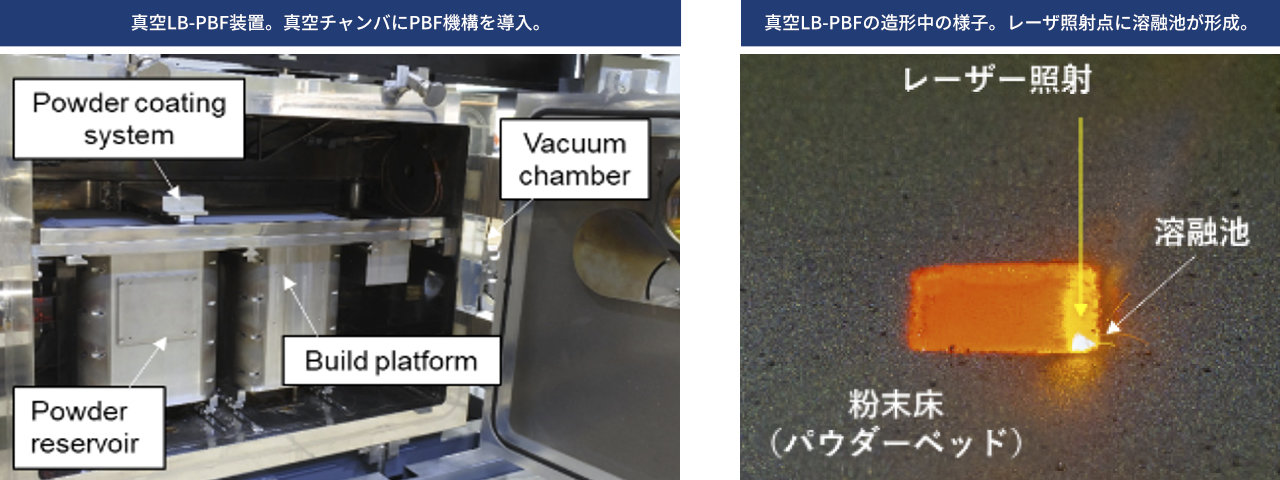

2.Vacuum laser-based powder bed fusion technology

Laser-Based Powder Bed Fusion (LB-PBF) AM generally uses an inert gas atmosphere, but changing the atmospheric pressure and gas type can change the melting and solidification behavior during fabrication and the mechanical properties of the fabricated objects. We have developed an LB-PBF system that can process in a vacuum atmosphere on the order of 0.01 Pa, and are studying to improve the shape and mechanical properties of PBF fabricated products by controlling the PBF process atmosphere.

-

3.High-speed 3D sand printing for metal casting molds

Utilizing the binder jet technology, we have developed a high-speed large 3D printer for sand molds that can realize thin-walled, complex-shaped castings. The world's fastest molding speed of 100,000 cc/h has been achieved, enabling mass production of automobile engine parts, etc. The sand mold printer is also being used for producing machinery and aircraft engine cast parts.

Related links

- Technology Research Association for Future Additive Manufacturing;TRAFAM

- https://www.trafam.or.jp

-

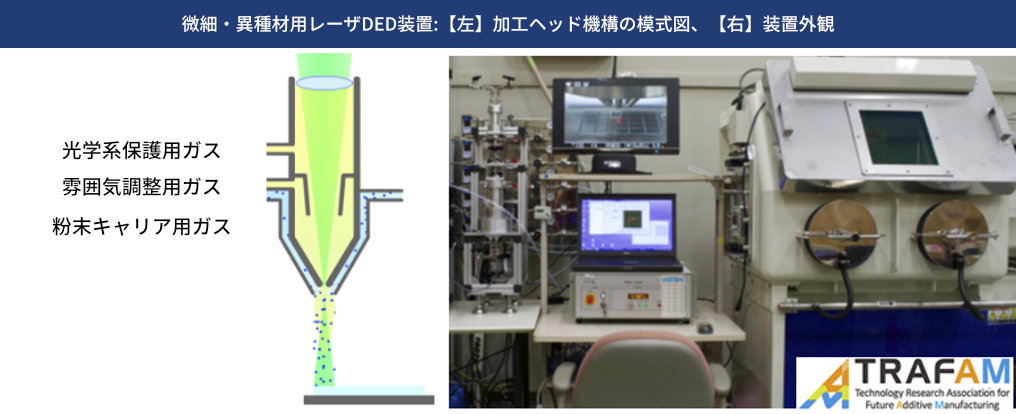

4.Development of laser-based DED for building fine structure and dissimilar material

Laser DED has the great advantage of fast building part in all of metal 3D printer. We would do the research and development of more precise control of shape of building part with various kind of metal material.

-

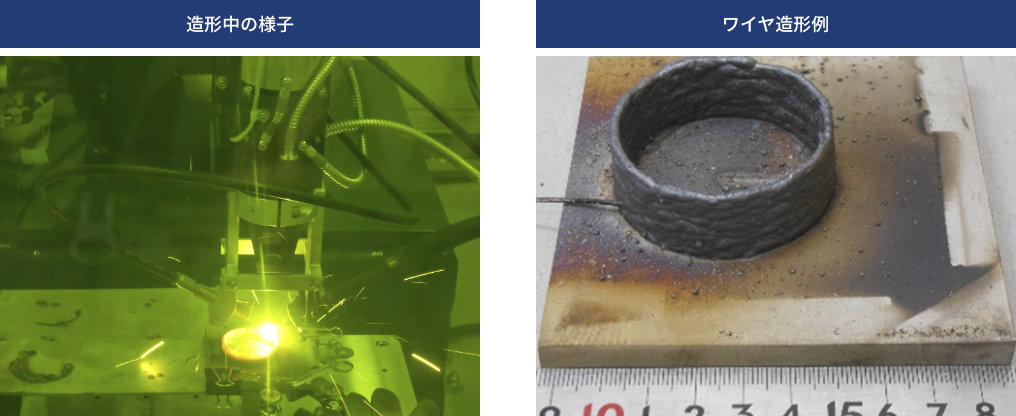

5.Study of wire-fed additive manufacturing technology using laser

Metal wire is cheaper and easier to deal than metal powder. Futhermore, metal wire can supply laminate material in high density on laser irradiation point. Thereflore wire-fed additive manufucturing is expected swift lamination easily. Therefore, we research wire DED technpology for high speed big volume lamination technique. we achieved 4kg/h lamination speed in normal wire feeeding, but we can achieve 8.1kg/h llamination speed when we select hot wire system which can supply wire in high temperature.

-

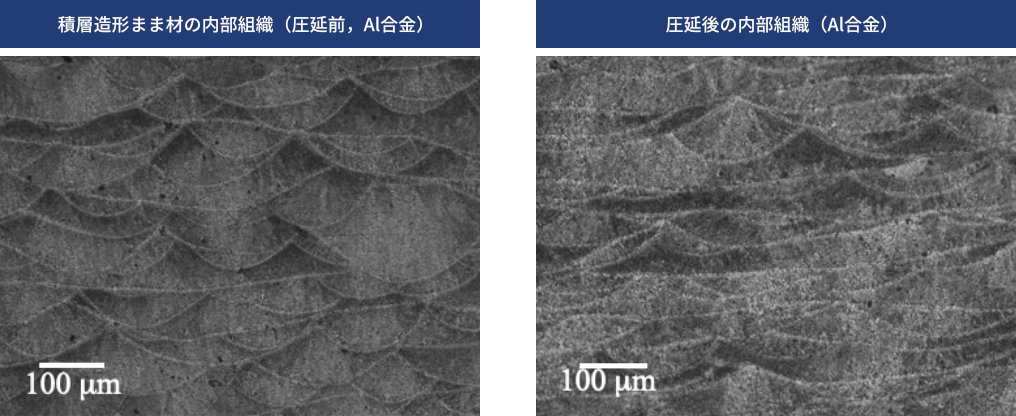

6.Development of a composite process of additive manufacturing and rolling

As a post-processing after additive manufacturing, we are working on the development of a process that combines rolling, which is plastic working. By giving plastic deformation, the internal structure of the material is significantly changed, and we aim to establish a manufacturing technology for the fabricated material with excellent mechanical properties such as high strength and high ductility.

-

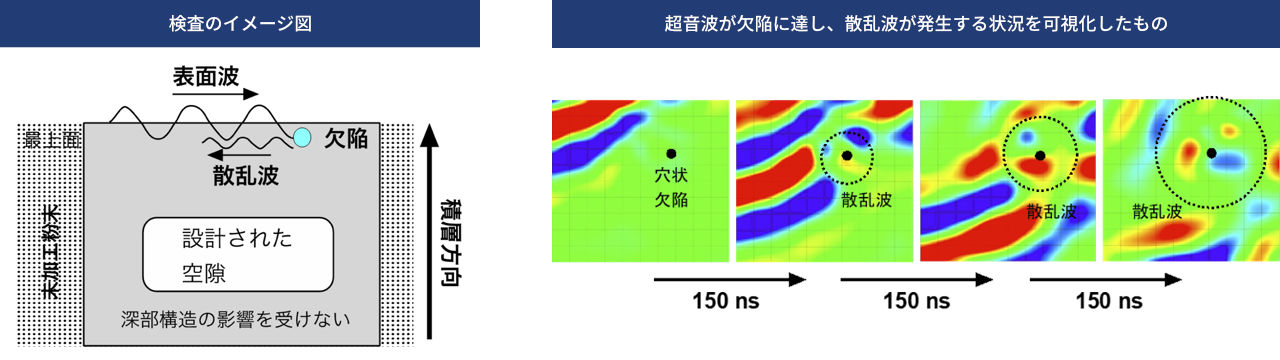

7.In-situ nondestructive inspection during additive manufacturing by using laser ultrasonics.

Laser ultrasonics (LU) is a technology to generate and to detect acoustic waves without contacting workpieces.

Our purpose is to develop an in-situ nondestructive inspection technology using LU to fit PBF system.

Our LU technology using surface acoustic waves will provide a promising inspection technology with high precision.