Theme

Development of Flexible Resistive Elements

Research keywords

Resistive element, High heat resistance, Flexible, Remanufacturing, Resource recycling

Research Objectives

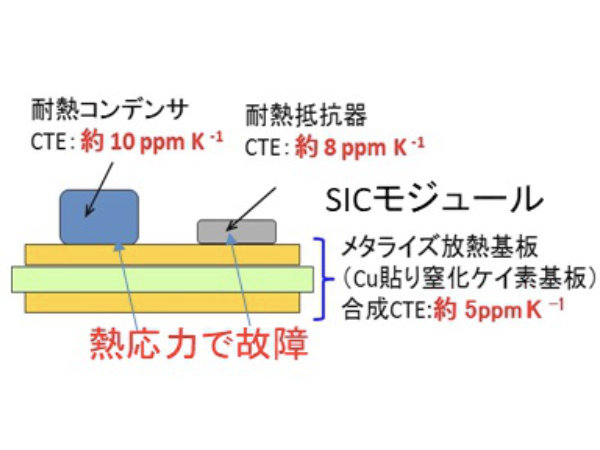

SiC is expected to be one solution to energy problems because its application in power devices enables low-loss power conversion that cannot be achieved with conventional Si power devices. In particular, next-generation SiC power modules are characterized by their ability to operate at high temperatures of around 200 to 250°C. However, conventional thick-film resistors are designed for 125°C or 155°C or lower, and heat resistance at 250°C, which is expected for SiC power modules, is not considered. Therefore, we have developed high heat-resistant resistors for SiC power modules.

Research Results

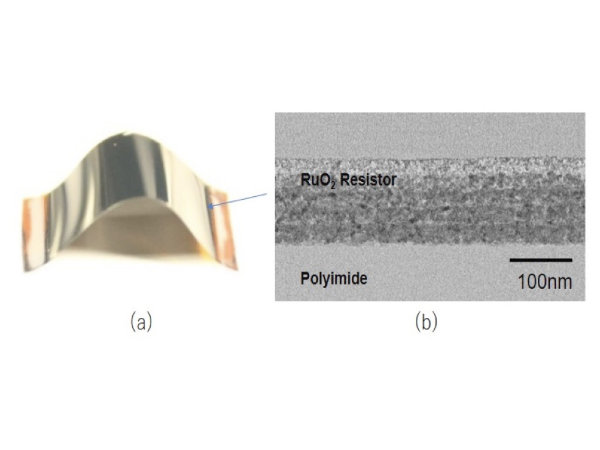

To adjust the temperature coefficient of resistance and resistance value, we have developed a hybrid solution photoreaction method in which an ink solution consisting of resistive particles and metal organic compounds is irradiated with light. By optimizing the film thickness and light irradiation conditions using this method, we have succeeded in fabricating resistive films with a sheet resistance of 0.5 to 10 Ω/sq at room temperature without a high-temperature heating process. In particular, since there is no heating process, the film can be fabricated not only on alumina substrates but also on polyimide substrates. In addition, it is difficult to recycle metallic ruthenium because conventional chip resistors mainly use a mixture of ruthenium oxide and lead-containing glass or materials to control the temperature coefficient of resistance. The newly developed flexible resistor film does not contain glass or other materials, which makes it possible to remanufacture RuO2 materials, thereby significantly reducing resource and environmental burdens as a recyclable electronic component.