Theme

The study for quality optimization of metal powders for additive manufacturing using plasma technology.

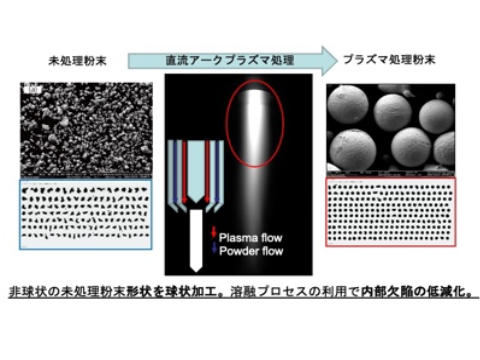

- DC arc plasma treatment for spherization of metal powders

- Internal-pore reduction of hard granulated powders

- Various types of plasma for treatment processes

Research Keyword

Additive manufacturing, Powders, Plasma, Plasma Applications, Spheroidizing Treatments by Plasma Process.

Research Objectives

We are developing plasma technologies targeting on the metal powders to optimize the properties as the raw materials of additive manufacturing (AM). This study will enable to modify the powders that have been unsuitable for AM to the usable ones for it, bringing greater flexibility of material selection in AM with low costs. The outcomes of this study therefore will lead to expand industrial applications of AM. To achieve these purposes, we are especially engaging in the development of the qualitative improvement and recycle technologies of metal powders using plasma processes.

Research Results

Raw powders used for AM are required high flowability and high packing density to achieve high process efficiency and to offer high-grade AM products. The requirements bring high costs and to restrict the usable materials in AM. To overcome the issues, we are studying a spheroidizing technology of metal powders using DC arc plasma. Some of the keys of this study are to clarify the melting behaviors of metal powders depended on the type of materials and to control atmosphere and plasma properly based on the melting behaviors, consequently allowing to obtain high-grade metal powders that have suitable properties for AM.

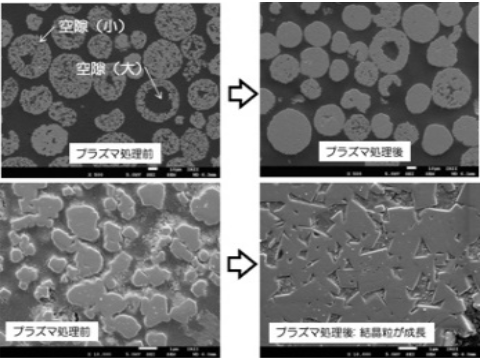

Until now, applying this study to some alloy powders including non-spherical stainless-steel powder and tungsten carbide granulated powder that is known as cemented carbide, we have successfully shown that this plasma technology enabled not only to spheroidize the powders and to remove the surface moisture of them but also to reduce the inner defects such as inner porosities and gaps between primary particles by reheating and melting under inert atmosphere.

At present we are examining the advantages of the plasma treated powders by conducting AM processes using them. Furthermore, we are actively engaging in developing a technology that integrates AM processing with powder treatment processing for fulfilling a new concept of AM.

Links(external publications, patents, related news, etc.)

- ”DC Arc Plasma Treatment for Defect Reduction in WC-Co Granulated Powder”, 板垣宏知、小木曽久人、佐藤治道、他、 Metals, vol.10, pp. 975-1-975-13, 2020.7

- “Spherical particles with and without attached nanoparticles formed by DC-Arc spheroidization of irregularly shaped stainless-steel powder”, 板垣宏知、花田幸太郎、廣瀬伸吾, Jpn. J. Appl. Phys., vol.59, pp.SJJG01-1-SJJG01-8, 2020.4.

- ”Characteristics of stainless steel powder of SUS316 Treated by Plasma Spheroidization using DC-Arc plasma”, 板垣宏知、花田幸太郎、廣瀬伸吾, Proceedings of ITSC2018, pp.806-810, 2018.5.