National Institute of Advanced Industrial Science and Technology (AIST)

National Metrology Institute of Japan

National Metrology Institute of Japan

Pressure and Vacuum Standards Group

About our group

We are developing, maintaining and providing the national standards of pressure, vacuum and leak.The pressure and vacuum standards are the basis of the pressure/vacuum measurements

using pressure gauges or vacuum gauges. The standards are also the fundamental technology

to support the leading-edge industries such as the aviation safety, semiconductor

or flat-panel display manufacturing.

We are continuing our research and development on upgrading our standards ranging from

ultra-high vacuum to ultra-high pressure to meet the strong demands from the industries.

Also we disseminate the national standards to the industries by supporting the Japan

Calibration Service System (JCSS) and providing the calibration services to the accredited

calibration laboratories.

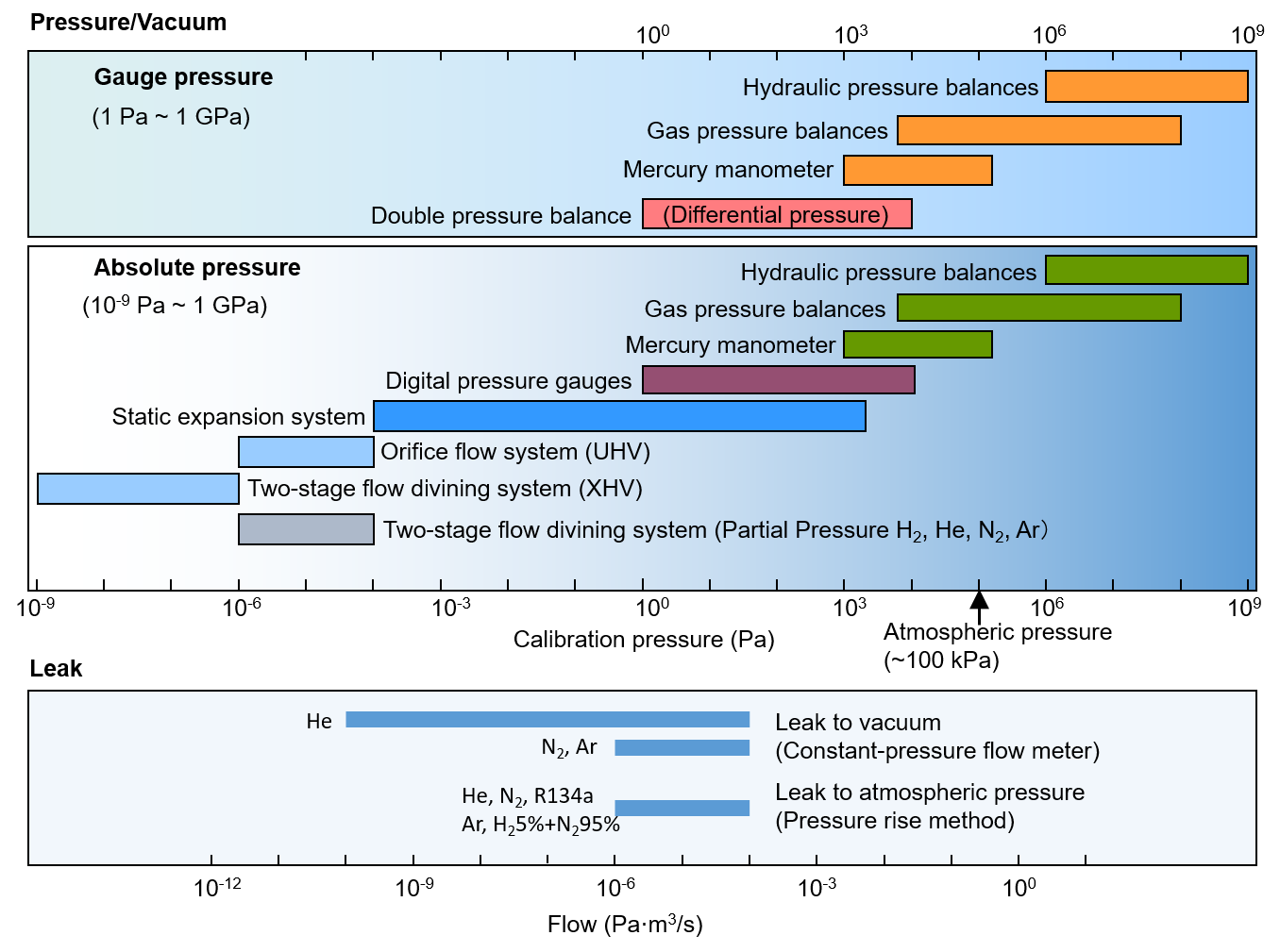

Our pressure, vacuum and leak standards

- Pressure standards using pressure balances

- Vacuum standards

- Leak standards for leak artefact calibration

Research topics

- Pressure

- Expanding the calibration range

- Low pressure calibration system below 1 kPa

- High gas pressure standard up to 100 MPa

- Dynamic pressure standard

- Upgrading pressure standards

- Precise evaluation of effective area of piston-cylinder by dimensional measurement

- Precise evaluation of pressure deformation coefficient of piston-cylinder by material characterization

- Precise characterization of pressure gauges

- Developing and upgrading calibration methods

- Automation of calibration procedure

- Development of precise calibration system using pressure transducer

- R & D for realization of pressure fixed points

- Vacuum and Leak

- Expanding the calibration range

- Ranges and gas species of the leak standard

- Evaluation of the reliability of vacuum gauges and leak artefacts, and their improvements

- Capacitance diaphragm gauges, spinning rotor gauges, ionization gauges, quadrupole mass spectrometers and leak artefacts

- Thermal transpiration effect

- "in-situ" calibration of vacuum gauges

- Gas dynamics in the molecular flow, the intermediate flow, and the viscous flow

- Gas species and their composition, surface roughness, etc

- ISO standardization of vacuum and leak

Calibration services

| Measurerand | Range | Standard | Instrument |

|---|---|---|---|

| Pressure (hydraulic) | 100 MPa to 1 GPa | Pressure balance + multiplier | Pressure measuring device |

| Pressure (hydraulic) | 1 MPa to 500 MPa | Pressure balances | Pressure balance, Pressure measuring device |

| Pressure (gas, gauge) | 5 kPa to 100 MPa | Pressure balances | Pressure balance (up to 7 MPa), Pressure measuring device |

| Pressure (gas, absolute) | 5 kPa to 100 MPa | Pressure balances | Pressure balance (up to 7 MPa), Pressure measuring device |

| Pressure (gas, absolute) | 1 Pa to 10 kPa | Pressure measuring devices calibrated by diff standard |

Pressure measuring device |

| Pressure (gas, differential) | 1 Pa to 10 kPa [Line pressure: 100 kPa +/- 10 kPa] |

Double pressure balance | Pressure measuring device |

| Low vacuum to high vacuum | 10-4 Pa to 2x103 Pa | Static expansion system | Spinning rotor gauge, Capacitance diaphragm guage |

| Ultra-high vacuum (UHV) | 10-6 Pa to 10-4 Pa | Orifice flow system | Ionization gauge |

| Extra-high vacuum (XHV) | 10-9 Pa to 10-6 Pa | Two-stage flow divining system | Ionization gauge |

| Partial pressure | 10-6 Pa to 10-4 Pa (N2, Ar, He, H2) |

Two-stage flow divining system | Partial pressure gauge |

| Leaks (into vacuum and atmospheric pressure) |

10-10 Pa m3/s to 10-4 Pa m3/s (N2, He, H2 5%+N2 balance, R 134a, Ar) |

Direct measuements or comparison with leaks generated by the flowmeters |

Leak artefact |

| Standard conductance | 10-11 m3/s to 10-8 m3/s [N2 equivalent] |

Two-stage flow divining system | Standard conductance element |

Contact

Pressure and Vacuum Standards Group

Research Institute for Engineering Measurement

National Metrology Institute of Japan (NMIJ), AIST

NMIJ Inquiry form