Research Teams

Automation RT | Connected Factory RT | Minimal Prototyping RT | Field Robotics RT

Dependable Systems RT | Smart-textile RT | Advanced Manufacturing and Evaluation RT

Mitsubishi Electric-AIST Human-Centric System Design CRL

Automation Research Team

| Research site: | AIST Tokyo Waterfront | member | |

|---|---|---|

| HP: | https://unit.aist.go.jp/icps/icps-am/ | |

Brief Introduction:

R&D of basic technology for machines (robots) to work dexterously and to share the environment with humans in order to increase their efficiency of automation and increase their affinity with humans. We conduct experiments on mock environments of factories and stores.

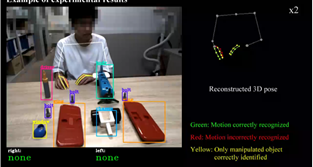

Article handling technology by robots

- Picking unknown parts without teaching

- Using AI and simulator it is possible to pick complex parts (e.g. tangled)

- Applicable to parts supply in factories and automation of store's display work.

- Determine which object and how it is being manipulated using images

- Applicable for the analysis of expert workers, robot motion planning, etc.

|

|

||

| Picking unknown parts assuming factory suply parts | Motion recognition of human, transfer to robot |

Connected Factory Research Team

| Research site: | AIST Tokyo Waterfront | member | |

|---|---|---|

| HP: | - | |

Brief Introduction:

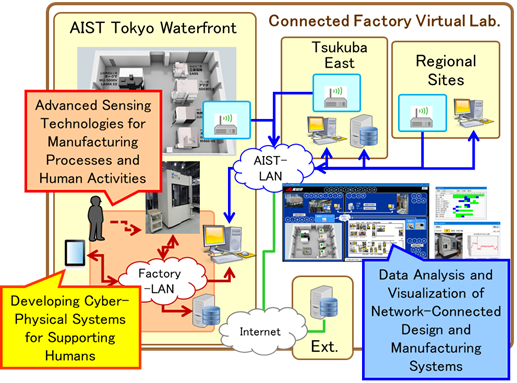

Studying advanced sensing technologies for design and manufacturing processes with human activities and developing analysis and visualization techniques for realizing cyber-physical systems of network-connected design and manufacturing systems for supporting humans

R&D of “Connected Factories” technologies

- Developing analysis and visualization techniques for network-connected design and manufacturing systems

- Studying advanced sensing technologies for design and manufacturing processes with human activities to integrate cyber and physical systems for supporting humans

- Making a proof study environment for “Connected Factories” between AIST and regional industrial technology organizations, and developing human resources for utilizing IoT

|

| R&D of “Connected Factories” |

Minimal Prototyping Research Team

| Research site: | AIST Tokyo Waterfront | member | |

|---|---|---|

| HP: | - | |

Brief Introduction:

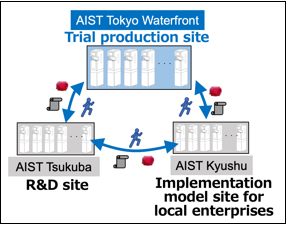

Demonstration of the practicality of productivity-enhancing technology as a high-mix low-volume manufacturing system focusing on Minimal fab with safety and flexibility

Device Prototyping Demonstration

- Trial production of devices using our Minimal process technology

- Factory development considering production stability and quality

- Developments of device process technology & Minimal control/monitoring technology in collaboration with Tsukuba Minimal site

- Running Minimal packaging tools, development of IoT sensor process technology and realizing “connected factory” mainly by remote operation in collaboration with Tosu(Kyushu) Minimal site

|

|

|||

| Integrated development system connected by movements of persons, objects and information between each site | Minimal fab in CPS building, Tokyo Waterfront |

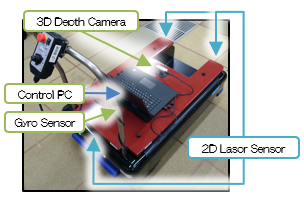

Field Robotics Research Team

| Research site: | AIST Tsukuba Central 2 | member | |

|---|---|---|

| HP: | https://unit.aist.go.jp/icps/icps-fr/ | |

Brief Introduction:

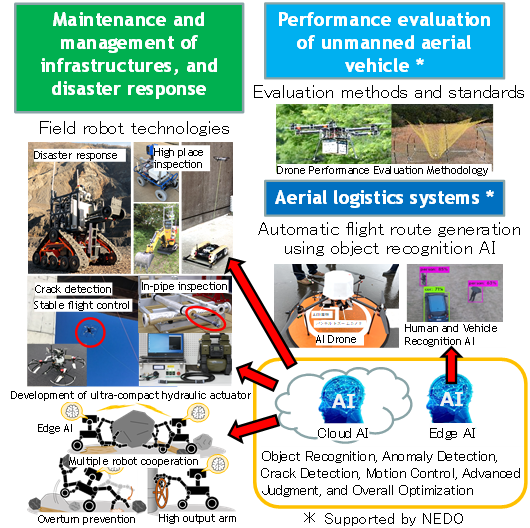

Development of field robot technologies, including operations, sensing, planning and control, for social and industrial infrastructures where aging and labor shortages are serious.

R & D of field robotics for maintenance and management of social/industrial infrastructure, and disaster response, including:

- Access technologies using land-sea-air field robots

- Ultra-compact hydraulic actuators to improve workability and motion performance of field robots

- Intelligent field robot technologies using Edge AI and Cloud AI

- Aircraft technical standards and control technical standards

|

Dependable Systems Research Team

| Research site: | AIST Tsukuba Central 2 | member | |

|---|---|---|

| HP: | - | |

Brief Introduction:

Advanced modeling, sensing, risk assessment, system design and other technologies related to human-robot cooperation in manufacturing, care services, and the use of AI to ensure safety and flexibility, workability and productivity

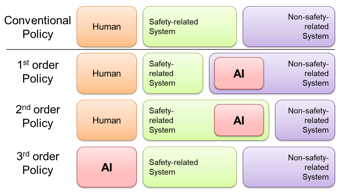

R&D, standardization for safety of service robots, industrial robots, and their testing methods

- Safety and effectiveness standards and testing methods for nursing care robots (AMED Project to Promote the Development and Introduction of Robotic Devices for Nursing Care)

- Risk assessment, safety certification schemes for agricultural robots, logistics robots, and station service robots

- Evaluation and testing technologies for optical safety sensors, a flexible robot-exterior sensor, and human detection sensors

- AI quality and reliability standards to ensure robot safety

- Safety evaluation platform for AI-equipped robots

|

|

||

| Toileting action aids | Testing for safety sensors | ||

|

|

||

| AI-equipped robots DRC-3 | AI Safety 3 Policies |

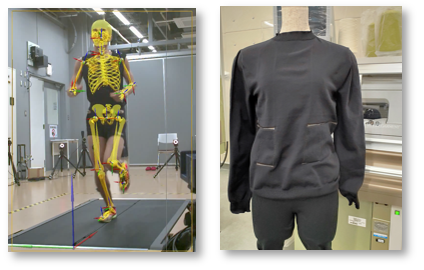

Smart-textile Research Team

| Research site: | Hokuriku Digital Manufacturing Center, AIST | member | |

|---|---|---|

| HP: | - | |

Brief Introduction:

Aiming for a safe and secure society for everyone, the project develops wear devices that can perform everything from sensing to intervention

without being noticed as a technology to accompany and enhance people, accelerate the servicing of manufacturing and create new industries.

From wearable devices to wearable devices

|

| Digital human-based motion analysis systems and knitted devices capable of sensing respiration and vitals. |

Advanced Manufacturing and Evaluation Research Team

| Research site: | Hokuriku Digital Manufacturing Center, AIST | member | |

|---|---|---|

| HP: | - | |

Brief Introduction:

We will promote R&D of digital manufacturing utilizing 3D additive manufacturing technology, which is excellent for on-demand manufacturing, and high-precision measurement technology, and will contribute to the spread and utilization of this technology in industry.

R&D of digital manufacturing using 3D additive manufacturing

- Construction of information processing system for 3D additive manufacturing consisting of CAD, CAM, and measurement loops

- Development of design methods suitable for additive manufacturing (DfAM) , and numerical simulation techniques for topology optimization, sintering, etc.

- Advancement of the fabrication process using binder jet metal 3D printer

- Fatigue strength evaluation by fatigue test, evaluation of external shape error by 3D shape measurement

- Crystal orientation analysis using electron microscope

- Realization of remote measurement systems connecting two sites in Hokuriku and Tsukuba

|

|

|||

| Binder jet metal 3D printer | Field Emission Scanning Electron Microscope (FE-SEM) |

Mitsubishi Electric-AIST Human-Centric System Design Cooperative Research Laboratory

| Research site: | AIST Tokyo Waterfront | member | |

|---|---|---|

| HP: | - | |

Brief Introduction:

To achieve "a 'prosperous future' that we should aim for beyond innovation," we will work to develop innovative technologies for a "personal wellbeing society" in which each individual is comfortable and healthy, and to realize a system design that integrates "CPS connecting industries".

Here, by focusing on the QoW of individuals, it is necessary to create an environment to maximize their abilities according to their working style and physical condition. In building the environment, it is important to establish a system that allows for control of the working environment without the constraints of physical and geographical space, as well as a system that allows for multiple tasks according to the capabilities of the individual.

This collaborative laboratory aims to realize integrated solutions that improve productivity and deliver a high level of comfort through a comfortable working environment with high QoW.

|