ハイブリッドセンシングデバイス研究チーム

チームメンバー

| 名前 | 役職等 | 拠点 |

|---|---|---|

| 竹井 裕介 TAKEI Yuusuke |

研究チーム長 |

つくば東 |

| 竹下 俊弘 TAKESHITA Toshihiro |

主任研究員 | |

| ZYMELKA Daniel | 主任研究員 | |

| 矢菅 浩規 YASUGA Hiroki |

研究員 | |

| 小林 健 KOBAYASHI Takeshi |

研究チーム付 経済産業省へ出向中 |

ー |

研究目標

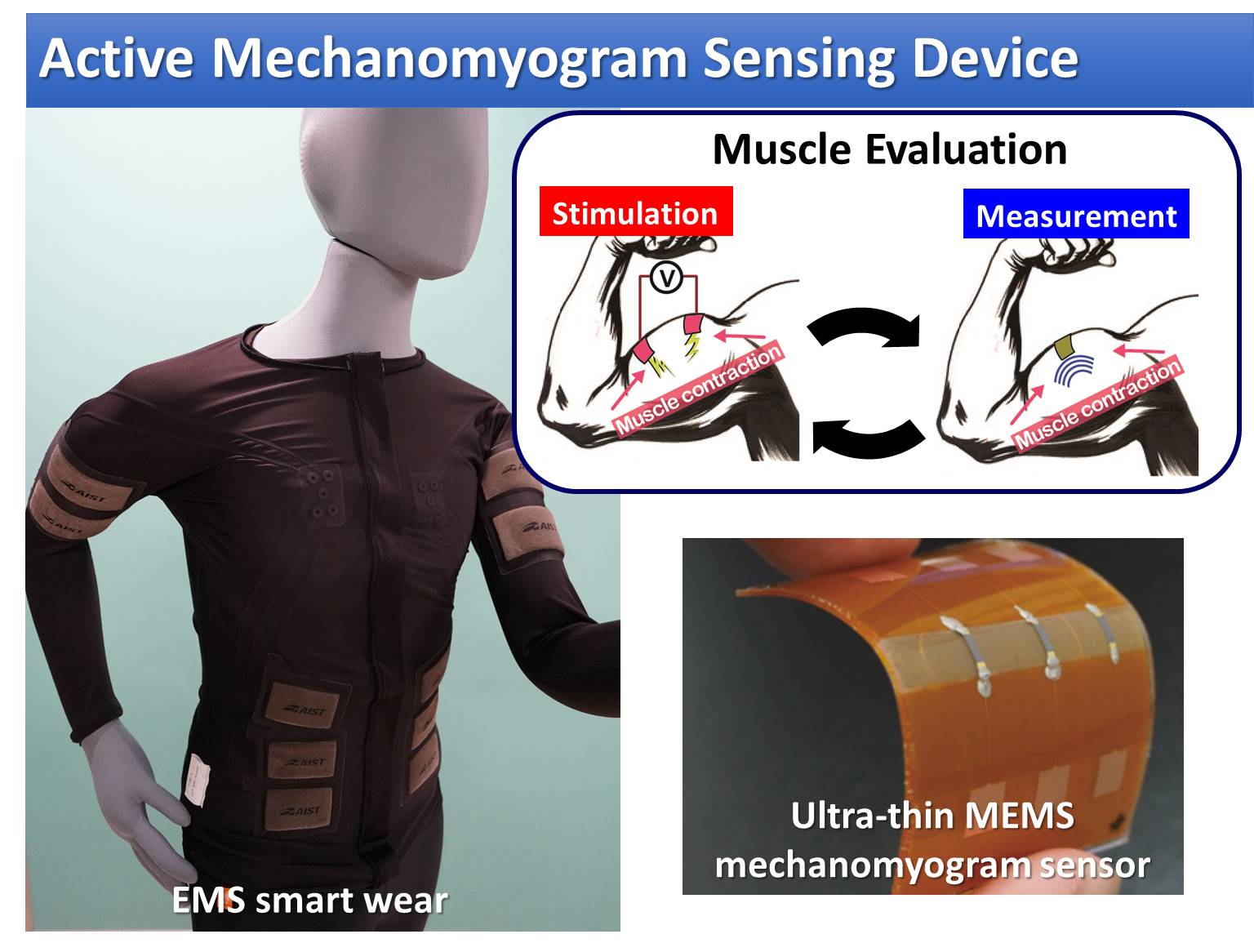

極薄MEMS、印刷エレクトロニクス、テキスタイルハイブリッドエレクトロニクス、無線センサデバイス、センサxAI高次情報センシング技術を統合したハイブリッドセンシングデバイスにより、ヒトのバイタルデータや筋力、インフラ構造物の劣化状態などをモニタリングするシステム実現を目指した研究開発を行っています。

保有技術

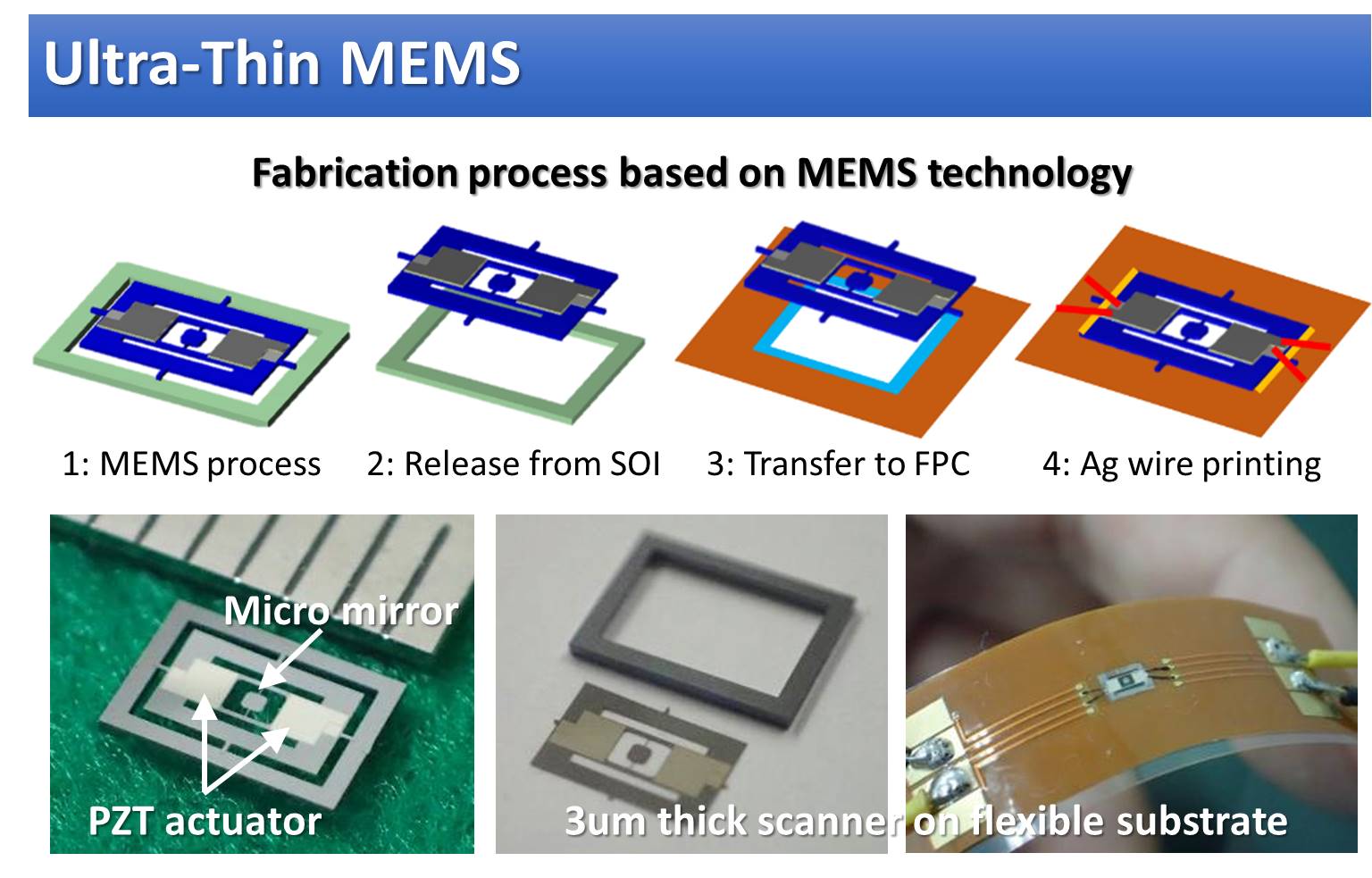

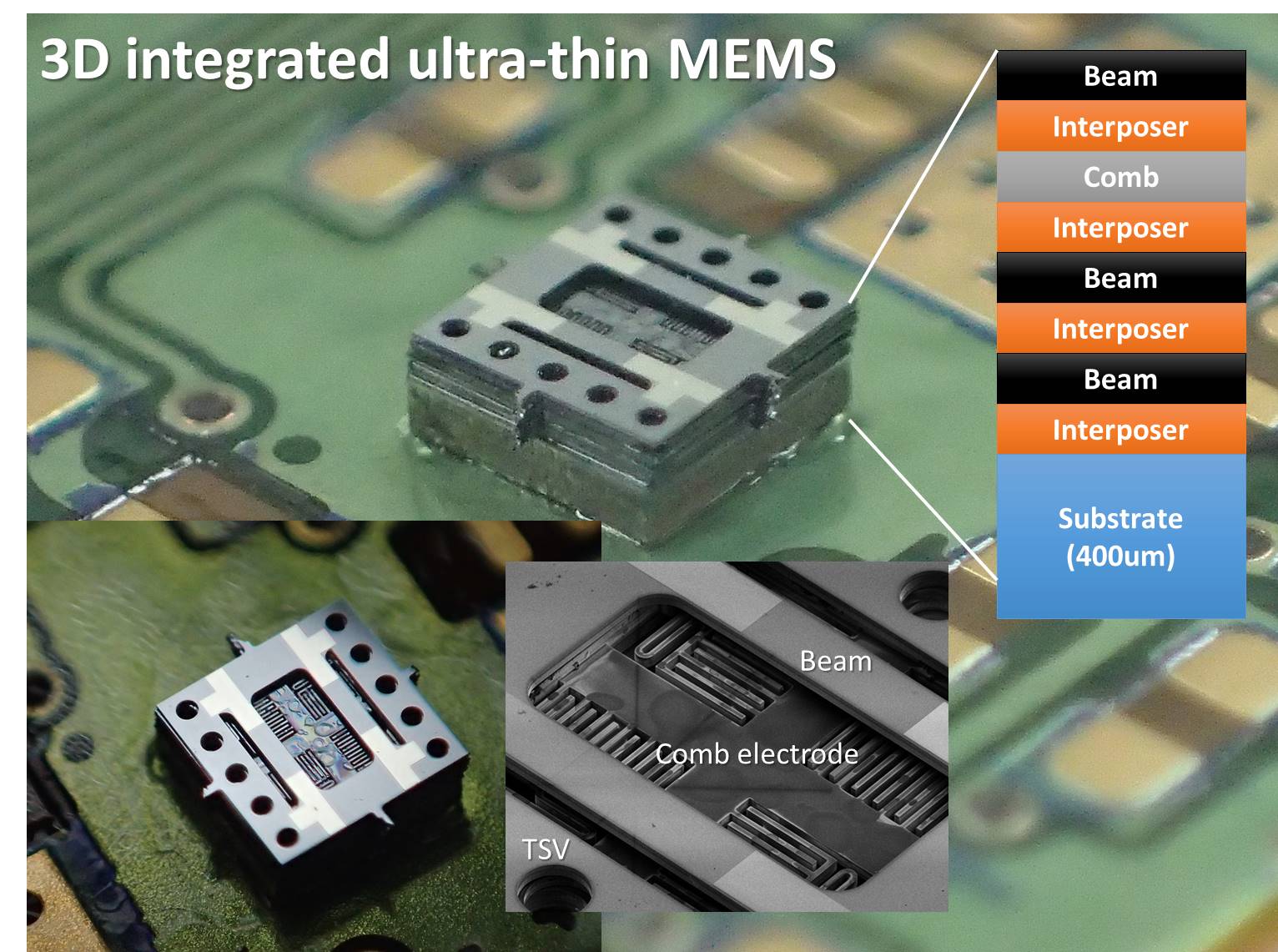

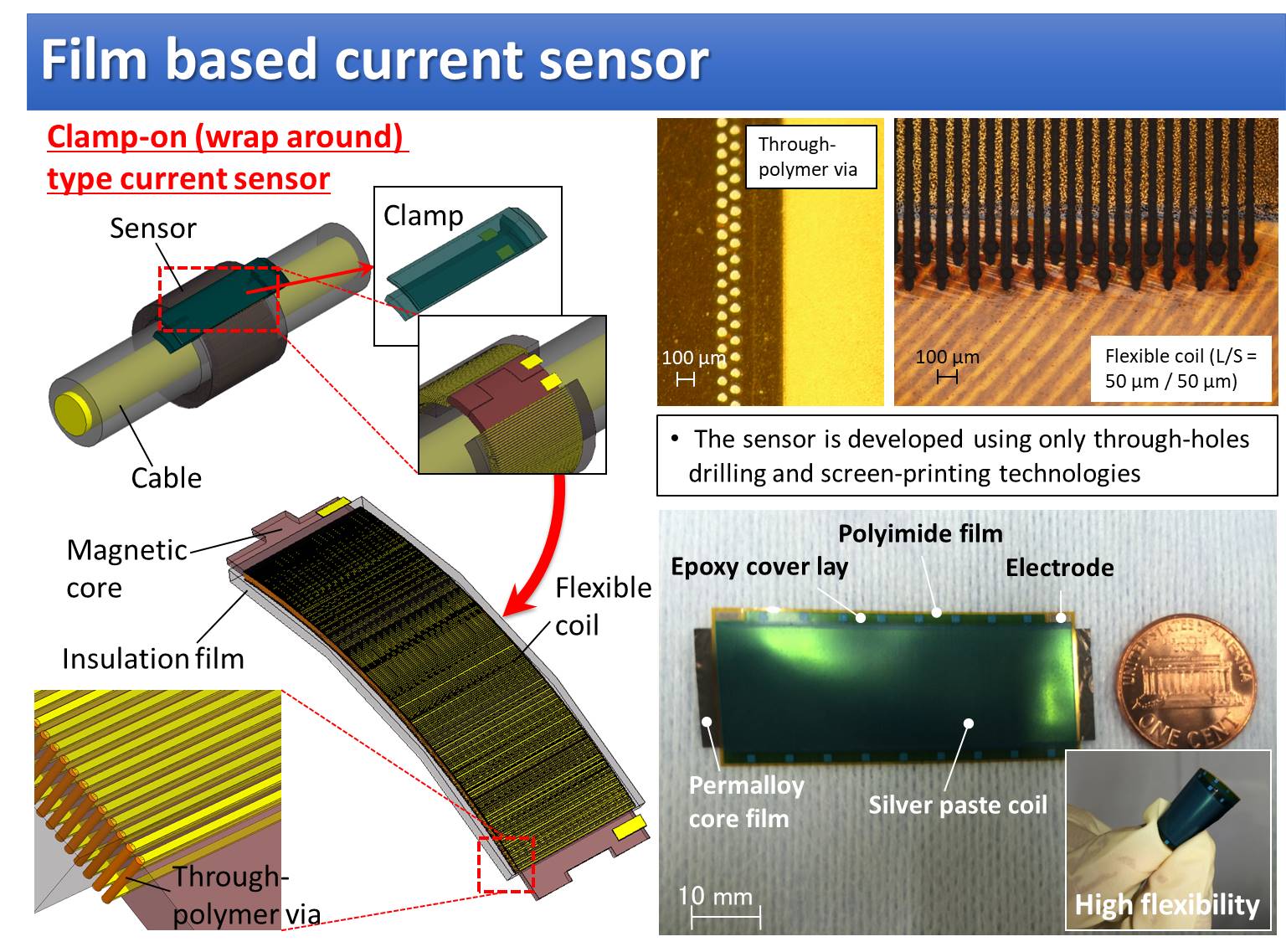

- 極薄MEMS

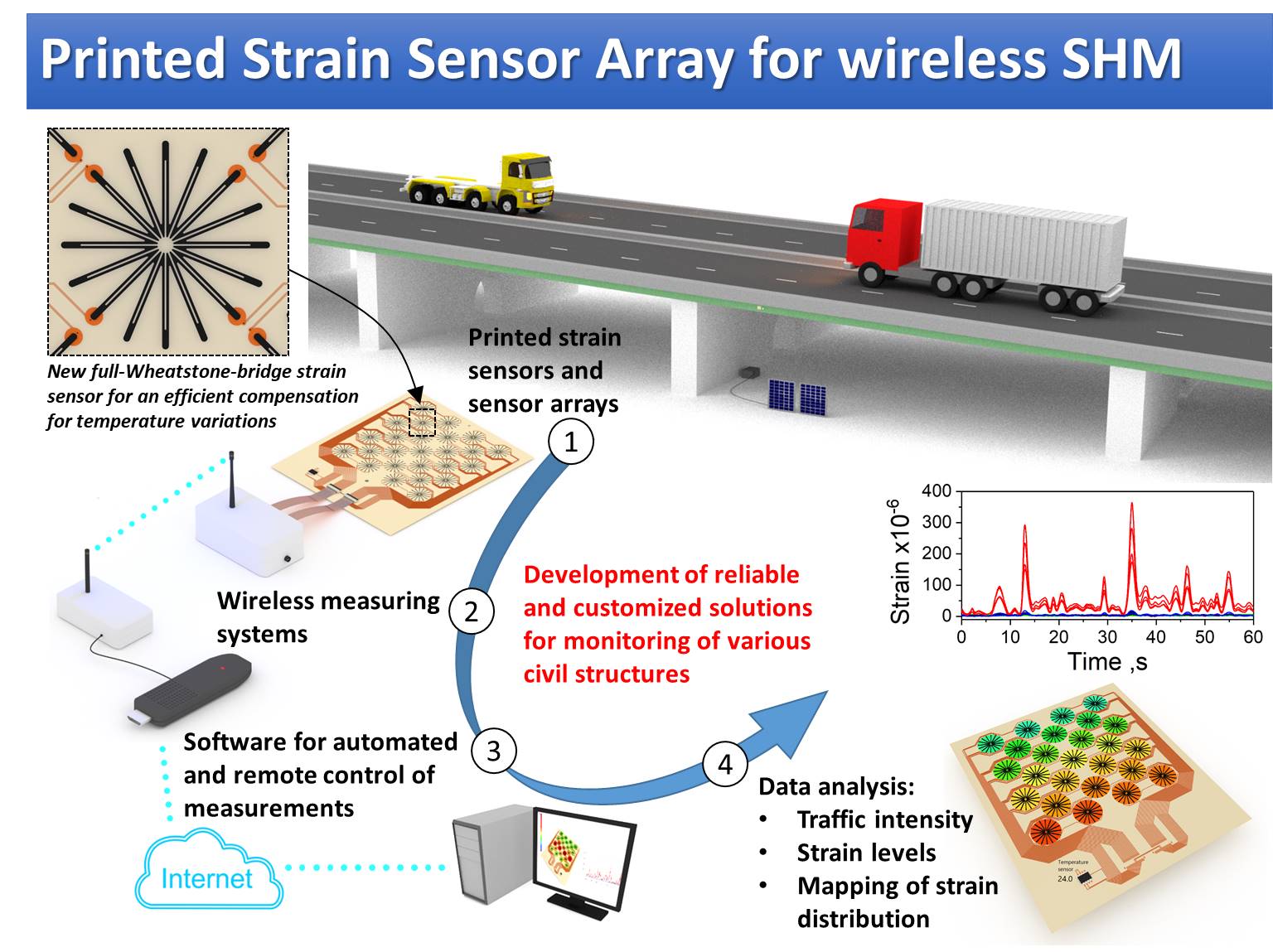

- 印刷エレクトロニクス

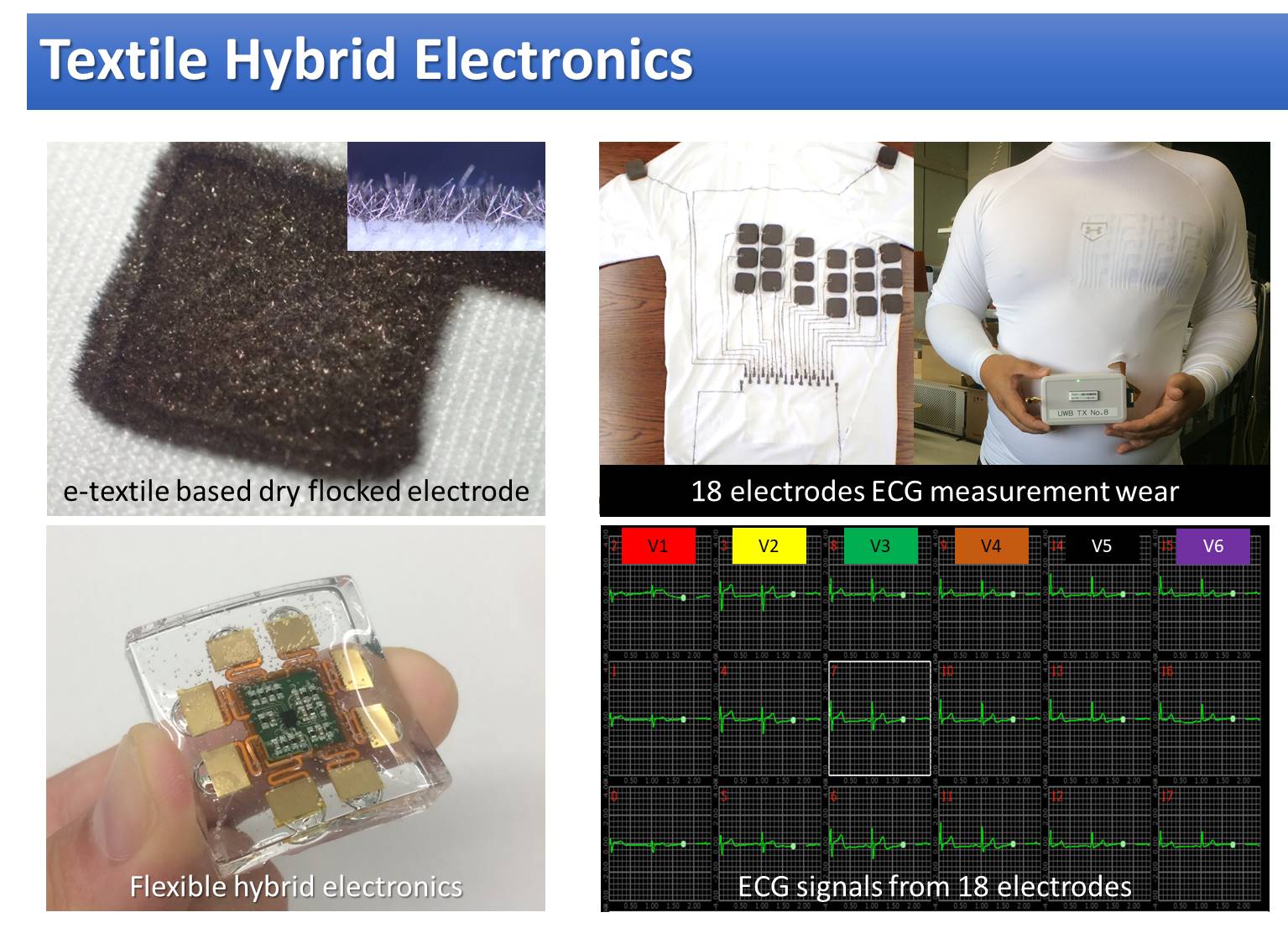

- テキスタイルハイブリッドエレクトロニクス

- 無線センサデバイス・システム

- センサxAI高次情報センシング

重点研究

主要特許・論文

- T. Takeshita, M. Yoshida, Y. Takei, A. Ouchi, A. Hinoki, H. Uchida, and T. Kobayashi, “Relationship between Contact Pressure and Motion Artifacts in ECG Measurement with Electrostatic Flocked ElectrodesFabricated on Textile”, Scientific Reports, 9, 5897 (2019)

- S. Takamatsu, S. Goto, M. Yamamoto, T. Yamashita, T. Kobayashi, and T. Itoh, “Plastic-scale-model assembly of ultrathin film MEMS piezoresistive strain sensor with conventional vacuum-suction chip mounter”, Scientific Reports, 9, 1893 (2019)

- Yusuke Takei, Ken-ichi Nomura, Yoshinori Horii, Daniel Zymelka, Hirobumi Ushijima, and Takeshi Kobayashi, “NOVEL METHOD FOR SIMULTANEOUSLY IMPLEMEMTING “WIRED FACE-UP AND FACEDOWN CHIPS” ON A FILM SUBSTRATE BY USING SIMPLE SCREEN-OFFSET PRINTING”, Proceeding of MEMS 2019, pp.182-183

- Yusuke Takei, Ryo Aoki, Takeshi Kobayashi, Tomoyuki Takahata, and Isao Shimoyama, “Mechanomyogram measurement by lead zirconate titanate-based acoustic sensor”, Jpn. J. Appl. Phys., 57 11UD09 (2018)

- Yusuke Takei, Manabu Yoshida, Toshihiro Takeshita, and Takeshi Kobayashi, “WEARABLE MUSCLE TRAINING AND MONITORING DEVICE”, Proceeding of MEMS2018, pp. 55-58

- Daniel Zymelka, Takahiro Yamashita, Seiichi Takamatsu, Toshihiro Itoh, and Takeshi Kobayashi, “Printed strain sensors for early damage detection in engineering structures”, Jpn. J. Appl. Phys., 57, 05GD05 (2018)

- Toshihiro Takeshita, Takahiro Yamashita, Natsumi Makimoto, and Takeshi Kobayashi, “Fabrication of an ultrathin lead zirconate titanate mirror device mounted on flexible substrate”, Jpn. J. Appl. Phys., 56, 10PF11 (2017)

- Toshihiro Takeshita, Takahiro Yamashita, Natsumi Makimoto, and Takeshi Kobayashi, “DEVELOPMENT OF ULTRA-THIN MEMS MICRO MIRROR DEVICE”, Proceeding of Transducers 2017, pp. 2143-2146

- T. Kobayashi, T. Yamashita, K. Togashi, R. Oohigashi, H. Okada, T. Takeshita, S. Takamatsu, and T. Itoh, “DYNAMIC STRAIN DISTRIBUTION SENSOR SHEET BASED ON ULTRA-THIN PZT/SI ARRAY ON FLEXIBLE SUBSTRATE FOR BRIDGE MONITORING WIRELESS SENSOR NETWORK”, Proceeding of Transducers 2017, pp. 327-330

- R. Takei, N. Makimoto, T. Tabaru, M. Akiyama, T. Itoh, and T. Kobayashi, “SCANDUMU ALUMINIUM NITRIDE VIBRATION ENERGY HARVESTER WITH A STRES COMPENSATION”, Proceeding of Transducers 2017, pp. 1879-1882

- Daniel Zymelka, Kazuyoshi Togashi, Ryoichi Ohigashi, Takahiro Yamashita, Seiichi Takamatsu, Toshihiro Itoh and Takeshi Kobayashi, “Printed strain sensor array for application to structural health monitoring”, Smart Mater. Struct., 26, 105040 (2017)

- Daniel Zymelka, Takahiro Yamashita, Seiichi Takamatsu, Toshihiro Itoh, and Takeshi Kobayashi, “Thin-film flexible sensor for omnidirectional strain measurements”, Sensors and Actuators A, 263, 391-397 (2017)

- Daniel Zymelka, Takahiro Yamashita, Seiichi Takamatsu, Toshihiro Itoh, and Takeshi Kobayashi, “Printed strain sensor with temperature compensation and its evaluation with an example of applications in structural health monitoring”, Jpn. J. Appl. Phys., 56, 05EC02 (2017)

- T. Kobayashi, T. Yamashita, N. Makimoto, S. Takamatsu, and T. Itoh, “Ultra-thin piezoelectric strain sensor 5 x 5 array integrated on flexible printed circuit for structural health monitoring by 2D dynamic strain sensing”, Proceeding of MEMS 2016, 1030-1033 (2016)

- Q. Shi, T. Wang, T. Kobayashi, and C. Lee, “Investigation of geometric design in piezoelectric microelectromechanical systems diaphragms for ultrasonic energy harvesting”, Appl. Phys. Lett., 108, 193902 (2016)

- R. Takei, H. Okada, N. Makimoto, T. Itoh, T. Kobayashi, “Simulation of an ultralow-power power management circuit for MEMS cantilever piezoelectric vibration energy harvesters”, Jpn. J. Appl. Phys., 55, 10TA06 (2016)

- R. Takei, N. Makimoto, H. Okada, T. Itoh, T. Kobayashi, “Design of piezoelectric MEMS cantilever for low-frequency vibration energy harvester”, Jpn. J. Appl. Phys., 55, 06GP14 (2016)

- T. Takeshita, N. Makimoto, H. Nogami, R. Sawada, and T. Kobayashi, “Simulation and fabrication of a MEMS optical scanner device considering deformation caused by internal stress”, Jpn. J. Appl. Phys., 55, 10TA11 (2016)

- T. Yamashita, S. Takamatsu, H. Okada, T. Itoh, and T. Kobayashi, “Ultra-thin piezoelectric strain sensor array integrated on a flexible printed circuit involving transfer printing methods”, IEEE Sensors Journal, 16, 8840 (2016)

- Takahiro Yamashita, Hironao Okada, Toshihiro Itoh, and Takeshi Kobayashi, “Manufacturing process for piezoelectric strain sensor sheet involving transfer printing methods”, Jpn. J. Appl. Phys., 54, 10ND08 (2015)