1. Development and evaluation of thermoelectric materials and modules

Thermoelectric materials development

|

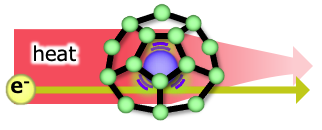

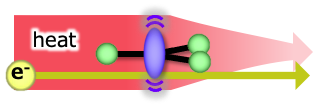

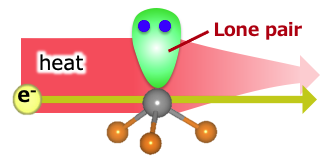

We are developing new high-performance thermoelectric materials to achieve high power generation performance. To achieve high thermoelectric performance, it is necessary to have both high electrical conductivity and low thermal conductivity. Our group is conducting research focusing on anharmonic vibrations of lattices that realize these contradictory properties. Anharmonic vibrations of lattices cause phonon-phonon scattering and suppress thermal conductivity. Usually, electrical conductivity also decreases, but there are some anharmonic vibrations that maintain electrical conductivity to a certain extent. For example, cage rattling, in which atoms packed in a large cage undergo large anharmonic vibrations, and anharmonic vibrations caused by lone pairs. Planar rattling, which does not require a large cage, is also promising. We are elucidating the dynamics of these anharmonic vibrations using neutron scattering and other methods, and developing new thermoelectric materials that utilize anharmonic vibrations.

|

|

|

Cage rattling

|

|

|

Planer rattling

|

|

|

Anharmonic potential due to lone pairs

|

|

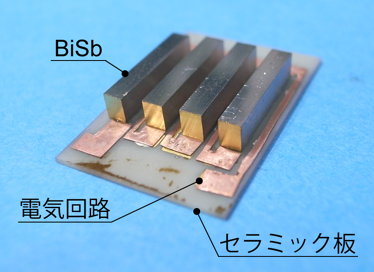

Development of thermoelectric modules

We are developing thermoelectric modules with high power output and efficiency. In recent years, various new high-performance thermoelectric materials have been discovered, and we aim to develop high-performance thermoelectric modules using them. Durability is a major issue for high-temperature thermoelectric modules. Therefore, we are continuously developing materials and electrodes that can withstand high temperatures.

Ordinary thermoelectric modules that use the Seebeck effect have a π-type structure that pairs p-type and n-type semiconductors. This π-type structure is the mainstream of Bi2Te3-based thermoelectric modules that are currently in practical use. In addition, there are Nernst effect-type modules that use magnetic fields. Although the performance of Nernst effect-type modules is still low, they have the advantage that they do not require a three-dimensional structure like the π-type structure and are relatively easy to fabricate. Our group is conducting research aimed at the practical use of both modules.

|

|

| π-type thermoelectric module |

Nernst effect module |

Thermoelectric module evaluation

|

We are developing evaluation technology for thermoelectric modules. In order to configure a power generation system using thermoelectric modules, it is necessary to know the exact power generation output and efficiency of the thermoelectric module. However, a unified measurement method for power generation output and efficiency has not yet been established. Therefore, our group is researching accurate power generation performance evaluation methods with the aim of establishing a unified measurement method. We also undertake contract evaluation of thermoelectric modules.

|

|

| Thermoelectric module power generation performance evaluation system |

|

|

|

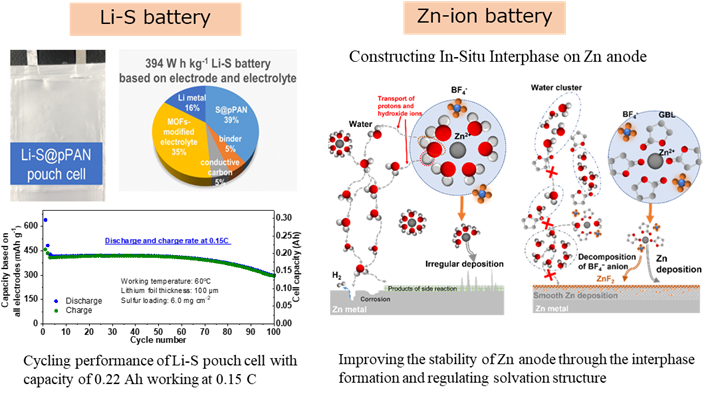

2. Development of next-generation post-lithium batteries

In order to popularize electric vehicles, there is a need for research and development of innovative secondary batteries that far exceed the performance of current lithium-ion batteries. However, innovative secondary batteries have various issues that must be resolved to achieve high reliability and safety. Therefore, it is essential to design new materials and elucidate reaction mechanisms of innovative secondary batteries such as lithium-ion batteries, sulfur batteries, and zinc-ion batteries.

Our group is working on improving battery performance by developing new materials, elucidating reaction mechanisms, and proposing new concepts.

3. Safety assessment of lithium-ion batteries through thermal analysis

In recent years, the number of lithium-ion battery fires has increased, making it important to evaluate the safety of batteries. The higher the temperature of a battery, the more it heats up, eventually resulting in thermal runaway. By investigating the heat generation characteristics, it is possible to predict the risk of thermal runaway in the environment in which the battery is used. Because there are reactions between battery components, heat generation that cannot be predicted from the heat generation characteristics of the individual components can be observed. Our group uses a custom-made device that can perform thermal analysis of 18650 cylindrical batteries as is, making it possible to perform measurements in conditions close to the real environment.

In electric vehicles (EVs) and battery energy storage systems (BESSs), which have been attracting attention in recent years, metallic lithium may be easily precipitated on the negative electrode when charged in a low-temperature environment. It is not yet clear how such conditions affect the heat generation characteristics of batteries. Our group is working to clarify how deterioration such as the precipitation of metallic lithium caused by use at low temperatures affects the safety of batteries.

|

|

|

C80 Calorimeter

|

|

|