Research theme: Research and development on advanced FT reaction and integrated process for liquid synthetic fuel production

Research objectives

By combining CO2 as a raw material with hydrogen and electricity derived from renewable energy and synthesis technologies, we will develop highly efficient integrated production technologies for liquid synthetic fuels that can replace liquid fossil fuels for internal combustion engines such as gasoline, diesel oil, and jet fuel in automobiles, thereby contributing to the realization of a sustainable society. Translated with www.DeepL.com/Translator (free version)

Contact person

Takehisa Mochizuki

Funding

NEDO project

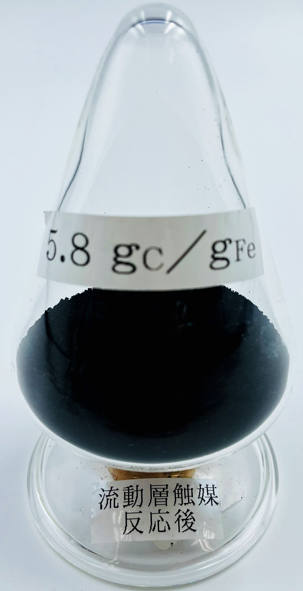

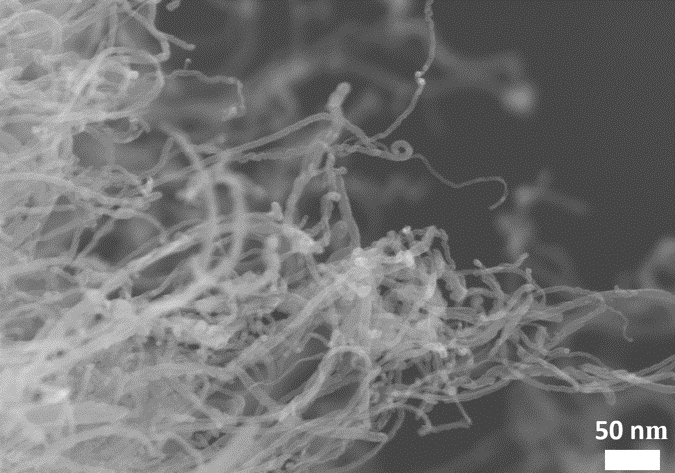

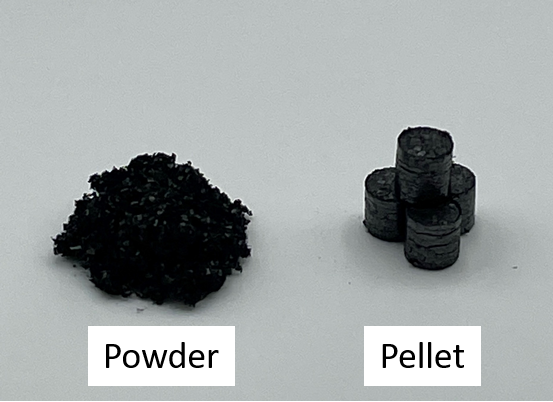

Research theme: Research and development of catalytic methane decomposition for COx-free hydrogen production

Research objectives

To accelerate the building of hydrogen society, we focus on (1) the development of COx-free hydrogen production technology using catalytic methane decomposition, which does not emit carbon dioxide, (2) the development of suitable reactors for catalytic methane decomposition, which plays an important role of hydrogen production technology.

Contact person

Shih-Yuan Chen

Funding

NEDO project

Powder Catalyst

Fluidized bed catalyst

Fluidized bed catalyst

Before reaction

After reaction

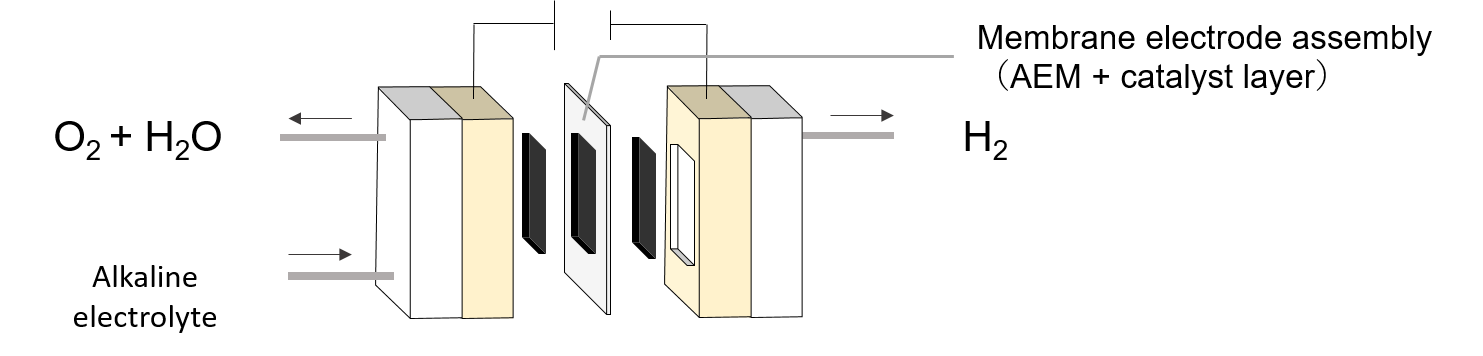

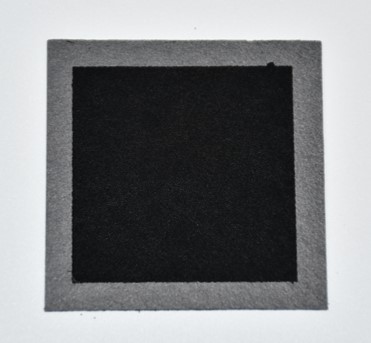

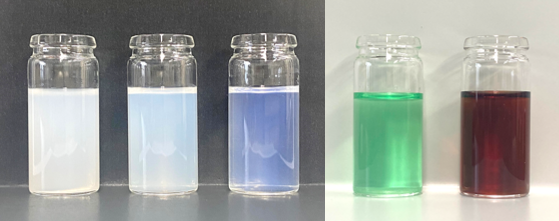

Research theme: Hydrogen production using an AEM electrolyzer

Aim

AEM water electrolysis is expected to be a low-cost, high-performance hydrogen production technology. Therefore, we have developed electrocatalysts for an AEM water electrolyzer, focusing on non-precious metal materials.

Topics

- Electrocatalyst

Project manager

Hiroyuki Tateno

Fundings

NEDO project

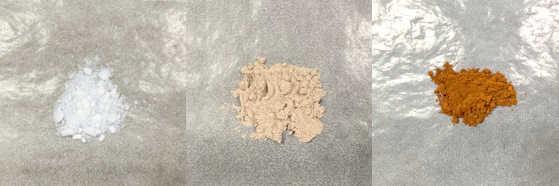

Research theme: Development of catalysts for fuel production

Objective

To realize carbon neutrality, catalysts for fuel production from CO2 and H2O are beeing developed.

Contents

- Catalyst development

- Control catalytic activity

- Investigate mechanism of catalyst

Contact person

Genki Horiguchi

Funding

Green Innovation Fund Projects

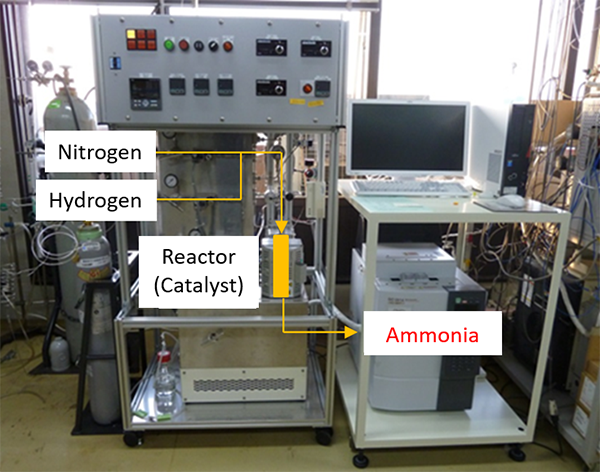

Research theme:Development of catalysts for ammonia synthesis

Research objectives

To reduce CO2 emissions during ammonia synthesis, we have developed catalysts for novel ammonia synthesis process by using hydrogen derived from renewable energy.

Contact person

Masayasu Nishi

Funding

JSPS KAKENHI

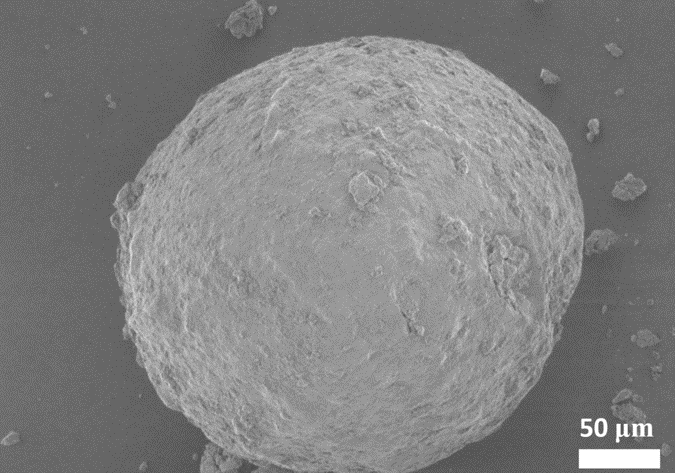

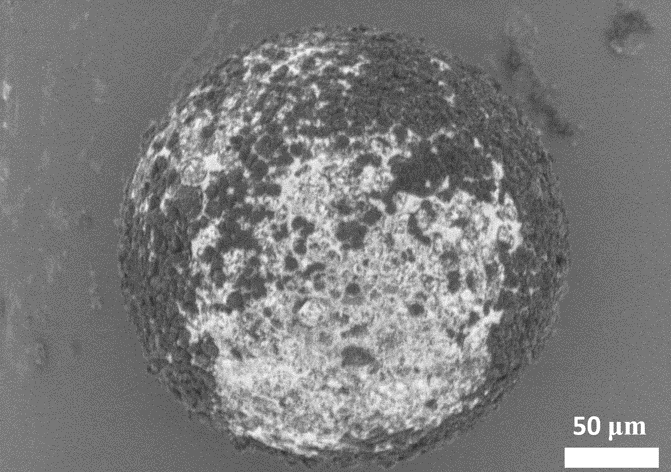

Research theme:Evaluation and control of particle characteristics

Objective

To achieve highly efficient energy recovery, methods to control charecteristics of particles (morphorogy, size, adhesiveness) are being developed.

Contents

- Synthesis for particulate materials

- Evaluation and control of particle characteristics at high temperatures

- Application to catalytic process

Contact person

Genki Horiguchi

Funding

Collaboration research, Grant fundin

Research theme:Low-cost hydrogen production using unused resources and solar energy

Research objectives

A large amount of cheap hydrogen is indispensable to realizing a low-carbon society. Therefore, we have developed catalysts and processes for low-cost and economical electrolytic hydrogen production.

Topics

- Utilization of unused resources for low-cost hydrogen production

- Solar-to-chemical conversion

Contact person

Hiroyuki Tateno

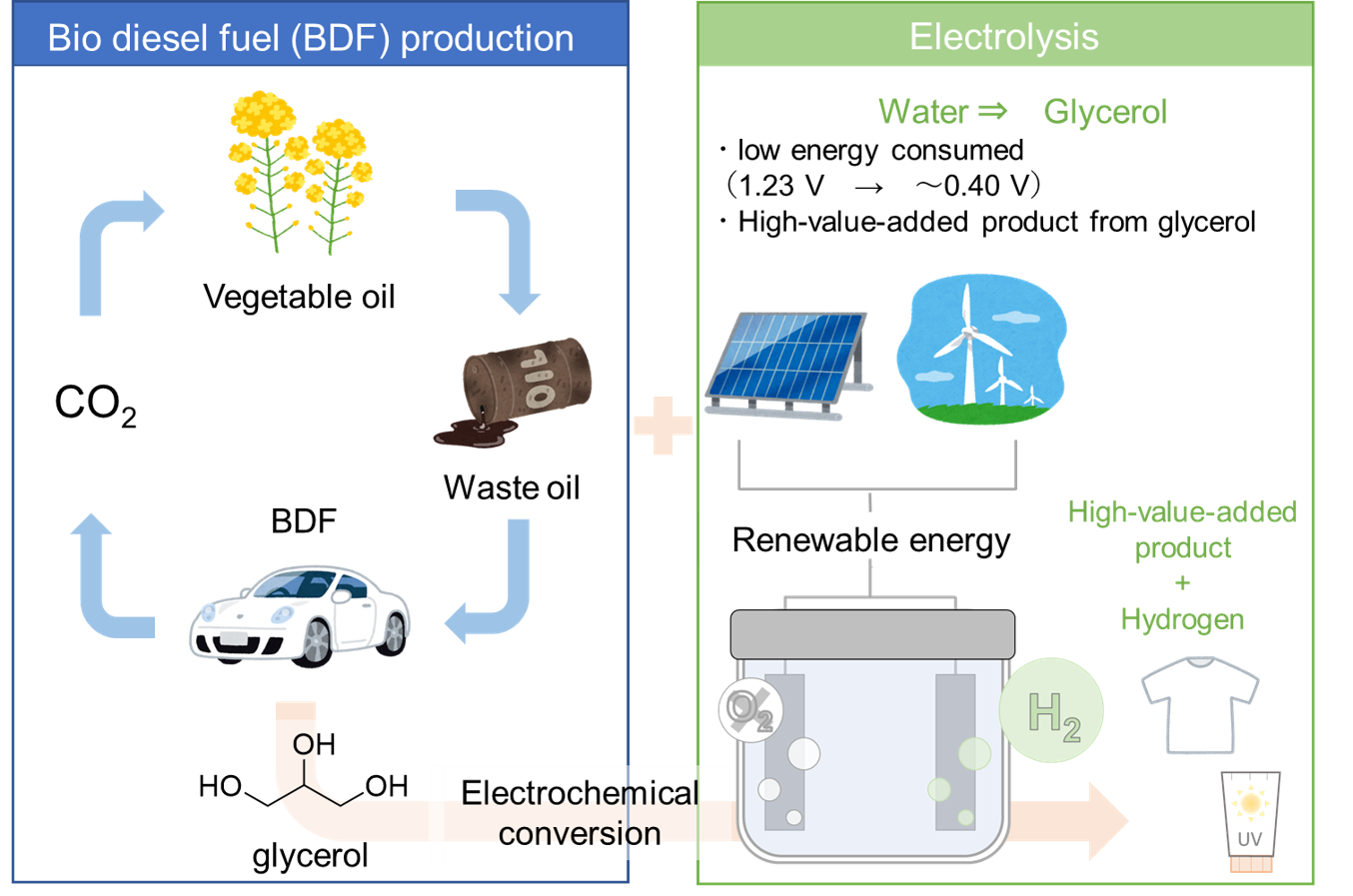

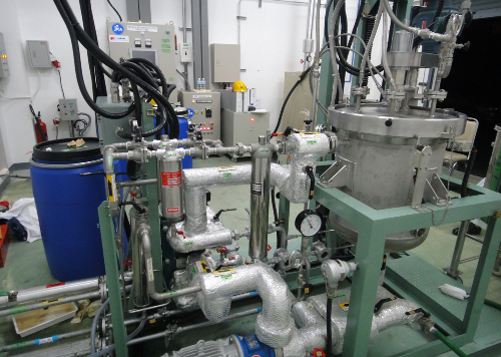

Research theme:Development of high quality biodiesel fuel production technology

Research objectives

To improve oxidation stability, which is an issue for biodiesel fuel, AIST has independently developed a partial hydrogenation technology that selectively reduces polyunsaturated components that are easily oxidized. Currently, AIST is working on the practical application of this technology mainly in cooperation with Thailand.

Contact person

Takehisa Mochizuki, Shih-Yuan Chen

(1.0 ton / day)

(100 L / batch)