Wind Power Research Team

Wind Power Operation & Maintenance (O&M) Improvement Technologies and Assessment Technologies

研究背景

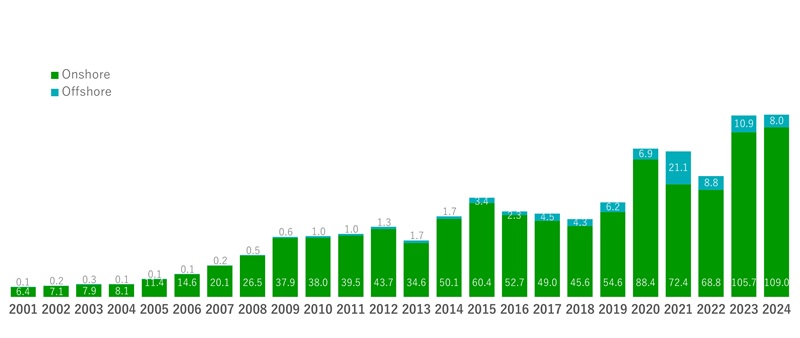

Offshore wind power now accounts for approximately 10% of annual global wind power installations, signaling the beginning of a full-scale offshore wind deployment.

Japan has set a goal of achieving carbon neutrality by 2050, and offshore wind power is regarded as one of the key technological areas to achieve this target.

To make wind power—particularly offshore wind—a mainstay energy source in Japan, it is essential to enhance the competitiveness of domestic related industries and further reduce the cost of energy.

Unit: GW; Green bars: Onshore wind; Blue bars: Offshore wind

Source: Created by AIST based on GWEC, Global Wind Report 2025

Research Target

To address challenges and promote the expansion of offshore wind power, the Public-Private Council for the Enhancement of Industrial Competitiveness in Offshore Wind Power formulated the “Offshore Wind Industry Vision (Phase 1)” in 2020, setting the following three public-private targets

- Form project pipelines totaling 10 GW by 2030 and 30–45 GW by 2040

- Increase the domestic procurement ratio to 60% by 2040

- Reduce the cost of bottom-fixed offshore wind power to 8–9 yen/kWh by 2030–2035

Our team aims to contribute to achieving these targets through technological support.

Specifically, we seek to provide technical support for the sound domestic deployment of offshore wind power and to enhance the domestic procurement ratio by collaborating with Japanese companies to develop, demonstrate, and commercialize advanced O&M (Operation and Maintenance) technologies.

In parallel, we also focus on fostering skilled human resources from universities and the private sector.

Research Outline

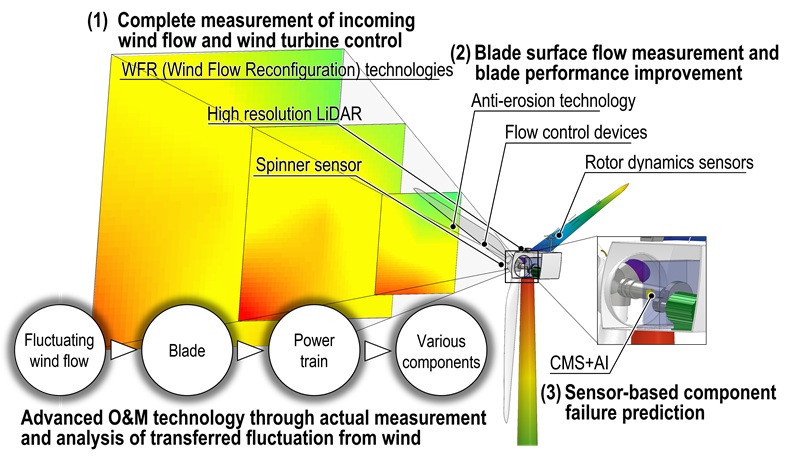

Wind Power Operation & Maintenance (O&M) Improvement Technologies

It is essential to develop, demonstrate, and commercialize advanced operation and maintenance (O&M) technologies (Figure 2) that can accommodate the diverse range of wind turbines—of various manufacturers and models—that are expected to be deployed in large numbers in the coming years.

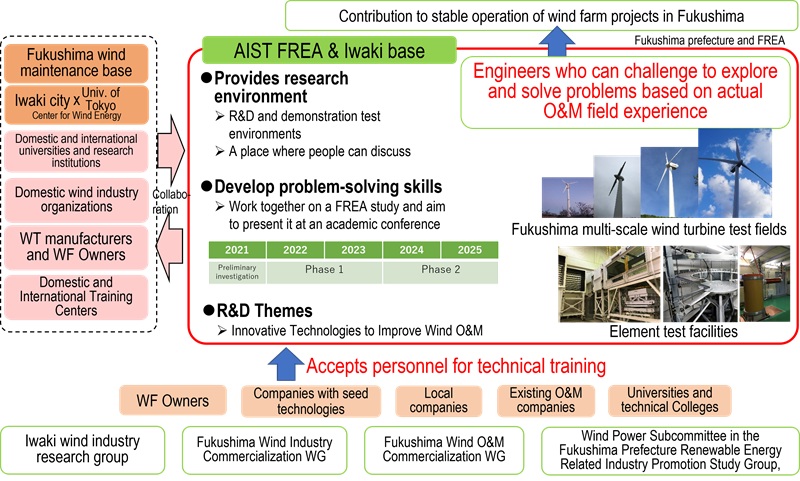

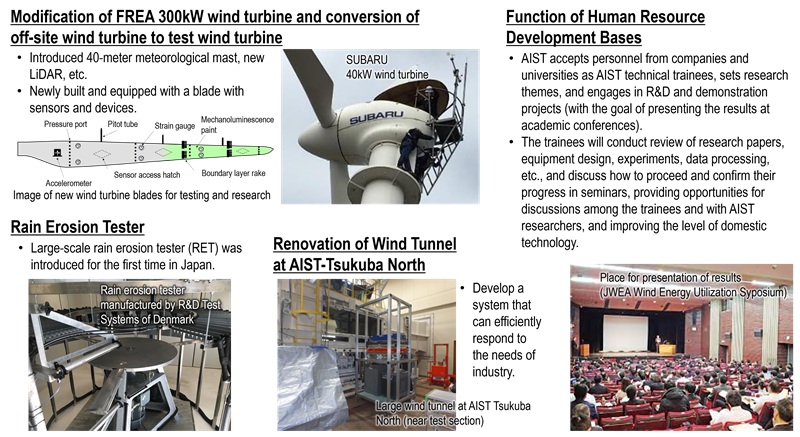

Establishment of a Hub for Technology Development and Human Resource Training in Wind Power Operation and Maintenance (FY2021–FY2025)

We have built upon our previous work—including basic research, joint research, and seed support projects—to undertake the project titled “Establishment of a Hub for Technology Development and Human Resource Training in Wind Power Operation and Maintenance” under the Subsidy for Support Projects to Promote the Introduction of Renewable Energy in Fukushima Prefecture (Fukushima Renewable Energy Institute Advanced Research and Hub Formation Support Project) (see Fig.3).

Through this project, we are building collaborative frameworks with domestic and international universities, research institutions, and wind power-related companies. By conducting joint research involving testing and providing technical consulting, we aim to foster skilled professionals in the industry and strengthen the competitiveness of Japanese companies.

Advancement of Wind Power Assessment Technologies

In the near future, the acquisition of offshore wind resource data—essential for the construction planning of large-scale offshore wind farms—is expected to become increasingly important.

It is necessary to establish measurement and survey methods that achieve both high reliability and low cost.

NEDO Project for Bottom-fixed Offshore Wind Farm Development / Establishment of Offshore Wind Resource Survey Methods (FY2019–FY2022)

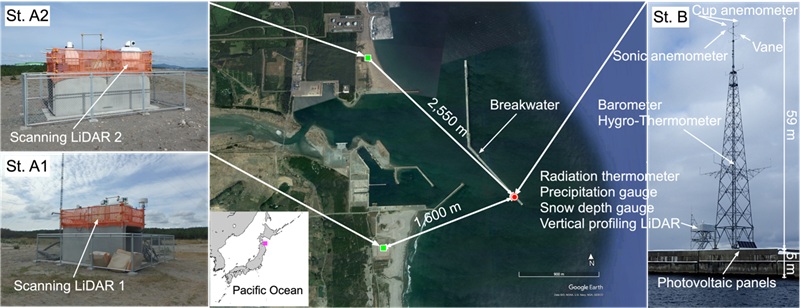

As the lead organization for the NEDO Project for Establishing Offshore Wind Resource Survey Methods*, we have conducted Japan’s first large-scale, long-term field experiments using multiple scanning LiDAR systems, successfully acquiring highly reliable demonstration data.

*: Jointly Commissioned Project by AIST, Kobe University, ClassNK, E&E Solutions, and Japan Weather Association

(NEDO Project for Establishing Offshore Wind Resource Survey Methods, FY2019–FY2022)

Activities and Achievements

Establishment of a Hub for Technology Development and Human Resource Training in Wind Power Operation and Maintenance

To develop and demonstrate advanced O&M improvement technologies, we have newly introduced a meteorological observation mast and a nacelle-mounted LiDAR system.

In addition, we are manufacturing wind turbine blades equipped with advanced sensors and devices, such as plasma flow control electrodes and stress luminescence paint.

We have also established an advanced testing and analysis environment by installing, for the first time in Japan, a large-scale erosion test apparatus manufactured by R&D Test Systems in Denmark (Figure 9), and by upgrading our existing large wind tunnel facilities.

Furthermore, we have built a collaborative framework with domestic and international universities, research institutes, and wind power-related companies.

Through joint research involving experimental testing and technical consulting, we are fostering skilled industry professionals and strengthening the competitiveness of domestic companies.

Offshore Wind Resource Survey Method Using Scanning LiDAR

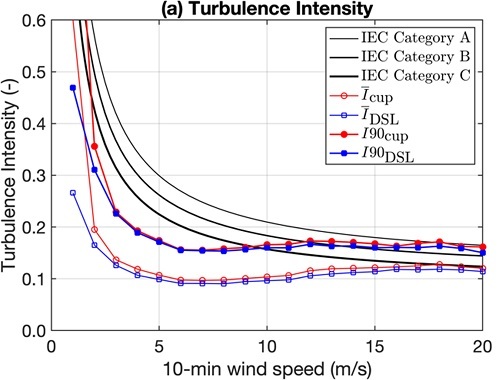

Through dual scanning LiDAR (DSL) measurements using two scanning LiDAR systems, we successfully established an offshore wind resource survey method that not only measures average wind speed but also accurately assesses turbulence intensity—an important factor in evaluating loads and fatigue life acting on wind turbines.

Compared to conventional methods using cup anemometers installed on meteorological masts, this approach demonstrated equivalent accuracy at just one-tenth of the cost.

Furthermore, this method served as the foundation for contributing to the development of NEDO’s “Offshore Wind Resource Measurement Guidebook” (published on April 6, 2023), which defines a standard offshore wind measurement methodology in Japan.

Through this contribution, we have provided technical support for achieving the national offshore wind deployment targets of forming 10 GW by 2030 and 30–45 GW by 2040.

<Related Information>NEDO “Offshore Wind Resource Measurement Guidebook”(Outbound link *This page is available only in Japanese.)

Red Line: Cup anemometer installed on a meteorological mast (Reference)

Blue Line: Measurement using dual scanning LiDAR systems (DSL)

Main Research Facilities

Research Wind Turbine: Komai Haltec KWT300 Modified

Rated Power: 300 kW, Rotor Diameter: 33 m, Hub Height: 41.5 m

This wind turbine is designed to withstand Japan’s severe external conditions, such as high turbulence caused by complex terrain. AIST has cooperated and contributed to its design phase through joint research.

It is a globally rare research wind turbine that allows advanced customization, including control systems. Equipped with cutting-edge sensors and devices such as nacelle-mounted LiDAR, plasma flow control electrodes, and stress luminescent paint, it is used to develop and demonstrate operation and maintenance (O&M) improvement technologies.

Nacelle-Mounted LiDAR

Rated Power: 300 kW, Rotor Diameter: 33 m, Hub Height: 41.5 m

This device emits laser beams in four directions in front of the wind turbine to measure and assess the wind speed and direction on the upstream side of the turbine.

The measurement data are used for evaluating turbine performance and for control operations that respond to incoming wind conditions.

Depending on the test requirements, the two LiDAR units can be configured with different scanning patterns for the laser beams.

Wind Turbine Blade Rain Erosion Tester

Rated power: 300 kW, Rotor diameter: 33 m, Hub height: 41.5 m

In offshore wind power generation, blade surface degradation caused by the impact of raindrops and other particles on rapidly rotating turbine blades—a phenomenon known as erosion—has become a significant issue.

To replicate this phenomenon on the ground, we have introduced specialized testing equipment. Utilizing this apparatus, we are collaborating with domestic companies to develop and demonstrate mitigation technologies.

Large-scale Wind Tunnel Testing Facility

Rated Power: Test section dimensions: 1.4 m × 1.4 m, Maximum wind speed: 48 m/s

This large-scale wind tunnel allows aerodynamic performance evaluation tests using wind turbine airfoils, achieving a Reynolds number of approximately 1.6 million (with a maximum chord length of 60 cm), which is comparable to the operating range of medium-sized wind turbines. Equipped with devices for generating unsteady flows and velocity-stratified flows, it can reproduce a variety of spatiotemporal inflow wind profiles.

In addition to fundamental fluid measurement instruments such as a six-component balance and hot-wire anemometers, the facility features a high-speed Nd:YLF (Neodymium-doped Yttrium Lithium Fluoride) laser and a high-speed camera, enabling time-resolved visualization measurements of the flow field.

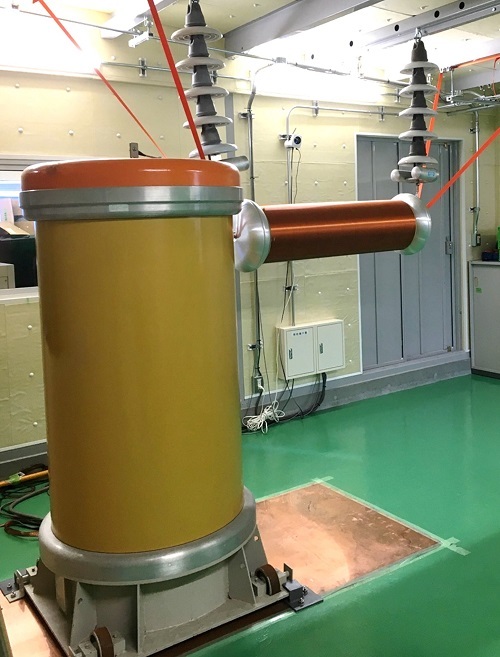

High-Voltage Test Equipment

Rated Power: The facility is equipped with commercial frequency voltage application devices capable of applying up to 200 kV and 50 kV, as well as a high-frequency voltage application device with a maximum voltage of 150 kV, enabling long-term insulation durability testing.

It is utilized for research on the insulation characteristics of various high-voltage devices, including plasma flow control electrodes.

Scanning LiDAR

This device emits laser beams and measures the Doppler shift of the reflected waves to determine wind speeds several kilometers away at intervals of a few seconds.

Team Member

| Title | Name |

|---|---|

| Leader, Team | SHIMADA Susumu |

| Senior Researcher | KAWABATA Hirokazu |

| Senior Researcher | TANAKA Motofumi |

| Senior Researcher | WATANABE Takeshi |

| Researcher | KUBO Noritsugu |

| Researcher | AIHARA Aya |