Hydrogen Energy Research Team

Hydrogen Technologies for Maximizing the Deployment of Renewable Energy

Overview

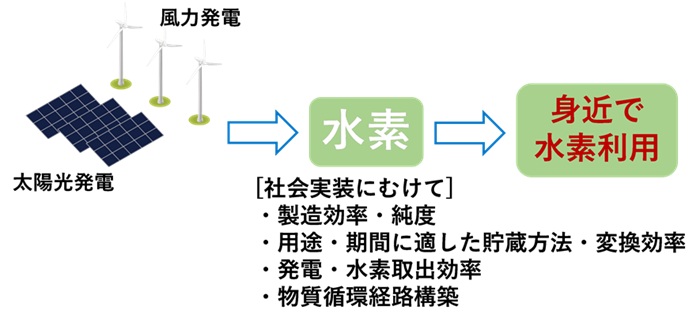

To achieve carbon neutrality, it is essential to increase the installed capacity of renewable energy (hereafter "RE") into society.

Solar and wind power are expected to expand significantly; however, their intermittency and variability due to weather conditions present a challenge.

Converting and storing RE in the form of hydrogen enables supply-demand balancing.

Furthermore, hydrogen can facilitate large-scale RE imports from overseas.

Technological advancements in hydrogen production, storage, and utilization from RE are key to realizing carbon neutrality.

Research Target

Our team aims to develop technologies that promote the societal implementation of hydrogen, which plays a vital role in utilizing variable renewable energy sources.

Research Outline

Hydrogen Production Technology

We are conducting research on water electrolysis technologies and systems to "produce" hydrogen using electricity derived from variable RE sources.

Establishment of a Water Electrolysis Evaluation Platform Under Renewable Energy Conditions

Under fluctuating RE conditions, water electrolyzers experience significant stress.

By studying the basic phenomena and establishing an evaluation platform under various operating conditions, we aim to enhance both domestic RE deployment and international industrial competitiveness.

Hydrogen Storage Technology

We are developing technologies and systems to "store" hydrogen—typically a gaseous substance that is difficult to handle under ambient conditions—safely and efficiently.

This includes hydrogen storage alloys, ammonia, and electrochemical hydrogen-carrier synthesis.

Cost Reduction and Social Implementation of Metal Hydride Tanks

Hydrogen can be stored in special metal alloys, called Metal Hydride, under mild conditions and later released as needed.

Utilizing this technology, we jointly developed the building-integrated hydrogen energy system Hydro Q-BiC🄬 with Shimizu Corporation.

The system is now being implemented in real-world projects and has been commercialized as a product series.

Hydrogen Utilization Technology

We are conducting research on integrated systems that “utilize” hydrogen, in combination with production and storage, and technologies that promote the circulation of elements such as carbon and nitrogen.

Ammonia Technologies for Small-Scale Distributed Renewable Energy Utilization

We have developed a small-scale ammonia synthesis system compatible with variable hydrogen production for decentralized RE storage.

Combined with technology to generate electricity via ammonia combustion (see Hydrogen Carrier Utilization Research Team) and a process to re-convert the post-combustion exhaust gas into ammonia using hydrogen, the system enables both resource recycling and carbon emission reduction.

Activities and Achievements

Establishment of a Water Electrolysis Evaluation Platform Under Renewable Energy Conditions

Through the Green Innovation Fund Project, three evaluation facilities were developed

- 1.A 500 kW-class proton exchange membrane (PEM) water electrolyzer test facility (<10 atm, DC input 500kW) for current-voltage characteristics under controlled temperature, accelerated degradation testing, and impedance/water analysis to identify degradation factors.

- 2.A high-pressure PEM water electrolyzer test facility (<50 atm, DC input 50 kW) for current-voltage and cross-leakage characteristics under high pressure conditions.

- 3.A water electrolyzer system test facility (Alkaline water electrolysis, <10 atm, DC input 500 kW) for evaluating power consumption, harmonic measurement, and other diagnostics under overseas power grids.

The resulting data contributes to standardizing evaluation methods and strengthening the global competitiveness of Japan's electrolyzer industry.

Cost Reduction and Social Deployment of Metal Hydride Tanks

While building-integrated hydrogen systems using metal hydride tanks such as Hydro Q-BiC🄬 are already being deployed, cost reduction is essential for widespread adoption.

By repurposing conventional heat exchanger, and introducing a proprietary hydrogen diffusion plate design (JP Patent 2024-125732), production costs were significantly reduced. CFD simulation of thermal fluid flow revealed the developed tank maintained high performance even under low-flow conditions.

A 350 Nm3hydrogen storage system employing the tanks was deployed for urban district heat supply, marking the world’s first hydrogen-based heat supply in a metropolitan area.

Ammonia Technologies for Small-Scale Distributed Renewable Energy Utilization

Following feasibility studies under the Strategic Innovation Promotion Program (SIP), we collaborated with Toyota Motor Corporation and Toyota Central R&D Labs to develop a compact ammonia plant.

We explored high-activity catalysts, multi-stage reactors, and optimized feed ratios to operate under ideal conditions.

The system includes a recycling mechanism similar to those in large-scale reactors, successfully synthesizing 1kg/day of liquid ammonia. Efforts are underway to enhance responsiveness to variability via modular scale-up.

Main Research Facilities

Water Electrolysis Evaluation Facilities

Three facilities for water electrolysis evaluation:

- 1.Large-scale PEM electrolysis (<10 atm, DC 500 kW)

- 2.High-pressure PEM electrolysis (<50 atm, DC 50 kW)

- 3.Alkaline electrolysis system under power grid conditions (<10 atm, DC 500 kW)

メンバー

| Title | Name |

|---|---|

| Leader, Team | MANAKA Yuichi |

| Senior Researcher | KOJIMA Hirokazu |

| Senior Researcher | KOBAYASHI Yasukazu |

| Senior Researcher | NAGASAWA Kensaku |

| Senior Researcher | OKUMURA Masahiko |

| Senior Researcher | CHAUDHARI Chandan |

| Senior Researcher | GOSHOUME Kiyotaka |

| Researcher | TSUDA Yuki |

| Attached to Research Team | ENDO Naruki |

| Attached to Research Team | MATSUNUMA Takayuki |

| Attached to Research Team | NISHI Masayasu |

| Attached to Research Team | KIMURA Tatsuo |

| Attached to Research Team | WAKABAYASHI Ryutaro |

| Attached to Research Team | TOMITA Atsuko |