Hydrogen Energy Carrier Research Team

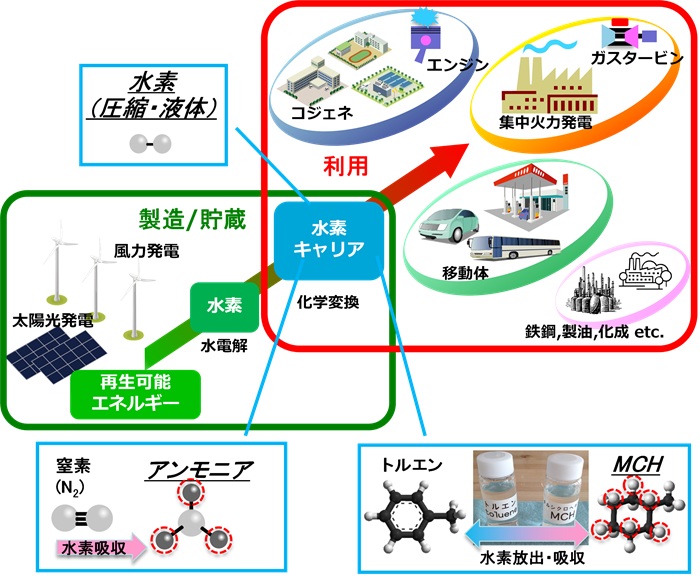

Development of technologies to promote the use of hydrogen carriers

Overview

To achieve a carbon-neutral society by 2050, it is essential to establish technologies for safely and efficiently utilizing hydrogen carriers in various applications.

Our team is developing technologies for the utilization of hydrogen (H2) itself and ammonia (NH3) synthesized from hydrogen as primary hydrogen carriers.

Additionally, we are conducting research and development related to hydrogen production.

As hydrogen carrier utilization technology, we are conducting research focused on energy conversion through combustion.

Specifically, we are engaged in R&D of “gas turbines,” “internal combustion engines,” “industrial furnaces,” and ‘boilers’ that utilize hydrogen carrier combustion.

Regarding hydrogen production, we are working on the development of “water electrolyzers.”

Research Target

In achieving carbon neutrality (CN) in manufacturing plants and other facilities, the use of hydrogen carriers as CN fuels in power generation, cogeneration, industrial machinery, mobility, industrial furnaces, and other applications directly contributes to reducing CO2 emissions.

We aim to establish technologies for efficiently and stably utilizing hydrogen carriers in energy conversion devices such as engines and gas turbines, which will remain indispensable in industry in the future.

Additionally, we are working toward the practical application of water electrolyzers that can produce hydrogen safely and at low cost.

Research Outline

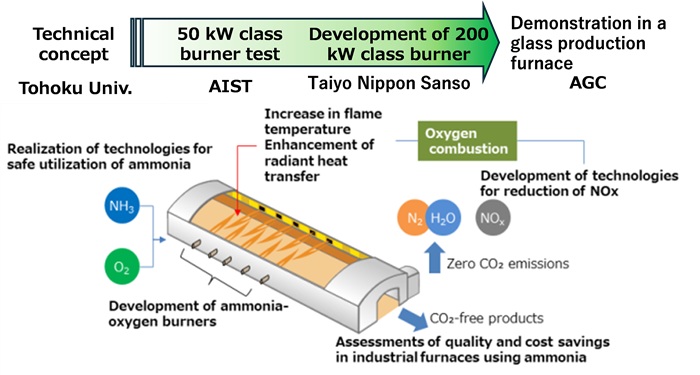

Combustion utilization of ammonia in industrial furnaces

CO2 emissions from heat supply facilities account for approximately 20% of total emissions.

In particular, industrial furnaces operating at high temperatures are difficult to electrify, making the use of carbon-free fuels a promising option for reducing CO2 emissions.

Our team is developing industrial furnaces that use ammonia as fuel.

Specifically, we have constructed a model furnace (inner diameter 0.4 m × length 2 m) capable of optical measurement and are conducting combustion tests of a 50 kW ammonia-oxygen burner employing NOx generation suppression and radiation enhancement techniques.

NEDO project ”Development of combustion technology for ammonia fuel in industrial furnaces” (FY2021-FY2025)

In this project, which is being conducted jointly with Taiyo Nippon Sanso Corporation, AGC Corporation, and Tohoku University, we are developing an ammonia-oxygen combustion burner designed to enhance flame radiation for glass melting furnaces.

We plan to evaluate radiation heat transfer and verify NOx reduction technology, followed by demonstration in an actual production furnace(Fig.1).

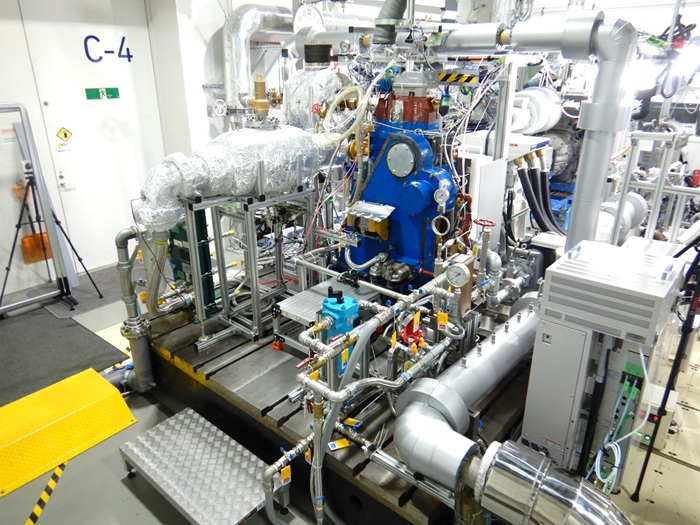

Development of hydrogen combustion engines

AIST is collaborating with companies to develop a 1 MW hydrogen engine aimed at achieving carbon neutrality in cogeneration systems for factories and other facilities.

Through evaluation tests on a single-cylinder engine modified from a four-stroke reciprocating gas engine (piston diameter 170 mm × stroke 220 mm), we have identified conditions for stable combustion using 100% clean hydrogen fuel without CO2 emissions.

We have also successfully achieved stable operation of hydrogen combustion equivalent to 6 cylinders/340 kW and 16 cylinders/920 kW (Fig.2).

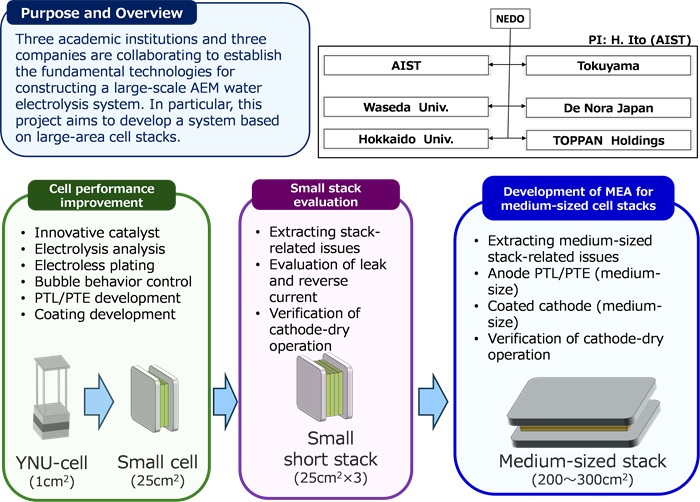

Development of anion exchange membrane (AEM) water electrolyzers

We are developing AEM water electrolysis devices, which are attracting attention as next-generation water electrolyzers capable of achieving low cost and high performance.

This device is a solid polymer membrane-type water electrolysis device that uses an anion exchange membrane (AEM) as the electrolyte membrane.

Since it operates in an alkaline environment, it has the potential to avoid the use of precious metal catalysts such as platinum (Pt) and iridium (Ir), and the cell components such as bipolar plates can also be made from inexpensive materials, making it highly promising for cost reduction. Similar to the preceding proton exchange membrane (PEM) water electrolysis, AEM water electrolysis employs an electrolyte membrane-electrode assembly (MEA) structure, enabling stable operation even at high current densities.

Our team conducts research and development on the optimization of electrode structures and electrolyte compositions, as well as on pressurized operation of AEM water electrolysis.

NEDO project “Development of MEA for large-area anion exchange membrane water electrolyzers※” (FY2023-FY2024)

We aim to commercialize a large-scale AEM water electrolysis system with a capacity of 1 MW by around 2030, focusing on “high functionality” and “large-area and stacking.”

Furthermore, we will work on establishing guidelines for commercialization based on the large-area cell (Fig.3).

※A joint project commissioned by AIST, Waseda University, Hokkaido University, Tokuyama Corporation, Denora Permerlec Co., Ltd., and TOPPAN Holdings Co., Ltd.

Activities and Achievements

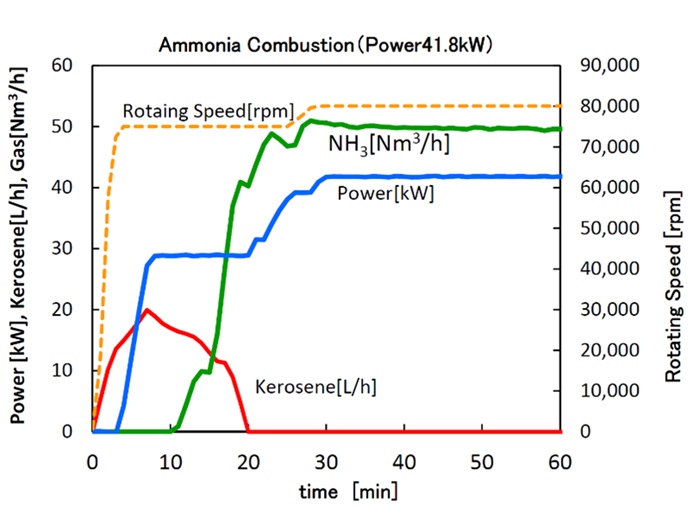

Ammonia combustion gas turbine

We are collaborating with universities and companies to develop small scale gas turbines that use ammonia as fuel.

Toward the social implementation of ammonia combustion gas turbines

We have successfully challenged the combustion utilization of a small gas turbine (50 kW rated) and achieved the world's first mixed-combustion operation of methane and ammonia, as well as 100% ammonia combustion operation (Fig. 4).

In addition, nitrogen oxide (NOx) emissions have been reduced to levels that fully comply with environmental regulations through the use of an ammonia excess/lean two-stage combustion concept.

Toward social implementation, we have promoted cost reduction through ammonia spray combustion and carbon neutralization of start-up fuel, and have also conducted demonstration tests in agricultural greenhouses.

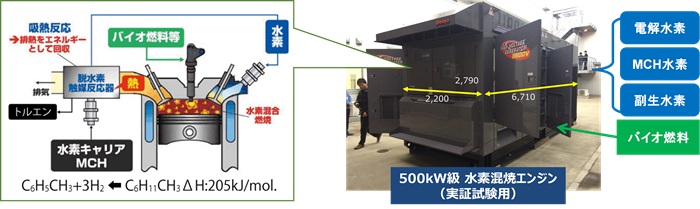

Demonstration of hydrogen supply chain and hydrogen-fired power generation system

We are developing a next-generation cogeneration engine using MCH, an organic hydride.

This engine development focuses on the development of engine exhaust heat recovery technology that utilizes engine exhaust heat for MCH dehydrogenation, as well as technology for hydrogen/ biomass fuel dual-fuel operation.

AIST, Hitachi, Ltd., and Denyo Kogyo Co., Ltd. have demonstrated the technology for a supply chain that manufactures hydrogen using renewable energy electricity and then generates electricity using a hydrogen power generation system after chemical conversion, storage, and transportation.

The hydrogen/biomass fuel dual-fuel engine power generation system achieved a total operating time of over 1,000 hours with a power output of 300 to 500 kW and a hydrogen ratio of 40 to 60%.

Some of the supplied hydrogen is produced by dehydrogenating MCH using engine exhaust heat, and by also utilizing biomass fuel produced within Fukushima Prefecture, this system is expected to become a decarbonized power generation system that is 100% locally sourced and consumed (Fig.5).

※MCH:Methylcyclohexane

Main Research Facilities

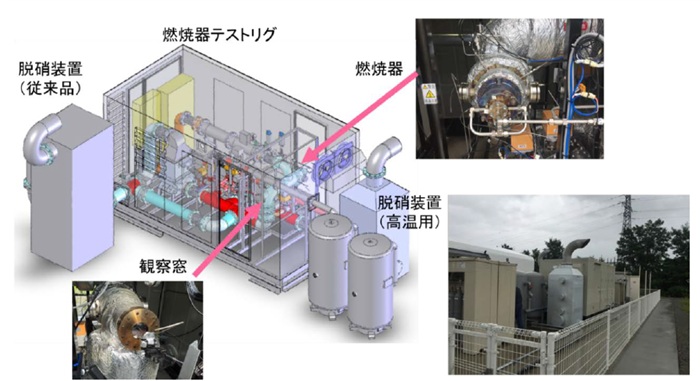

Rig testing equipment for gas turbines(FREA)

Rig testing equipment that can reproduce the internal conditions of an ammonia gas turbine combustor.

Bench-scale testing of various combustors and injection nozzles, as well as visualization and observation of combustion conditions, are possible.

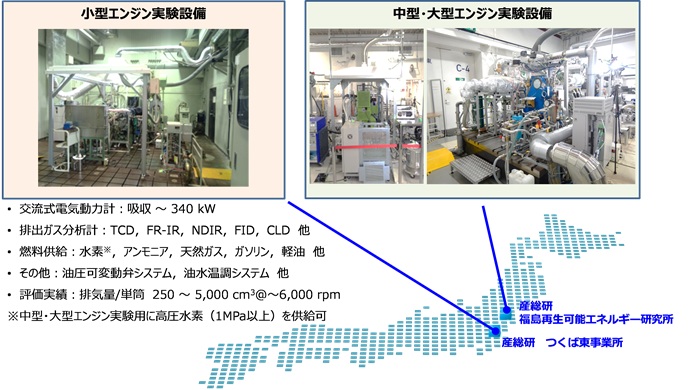

Hydrogen/ammonia fuel reciprocating engine evaluation equipment(FREA,Tsukuba)

We can evaluate carbon-neutral fuels such as hydrogen and ammonia for reciprocating engines ranging from small to large.

We have experience in evaluating hydrogen-only combustion, mixed combustion with hydrogen and natural gas, ammonia, and light oil, as well as high-pressure hydrogen gas evaluation.

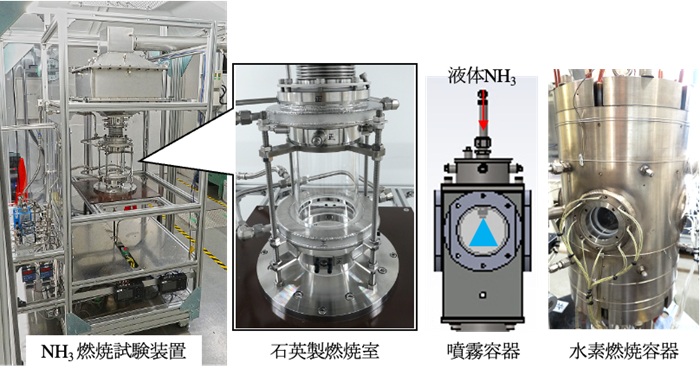

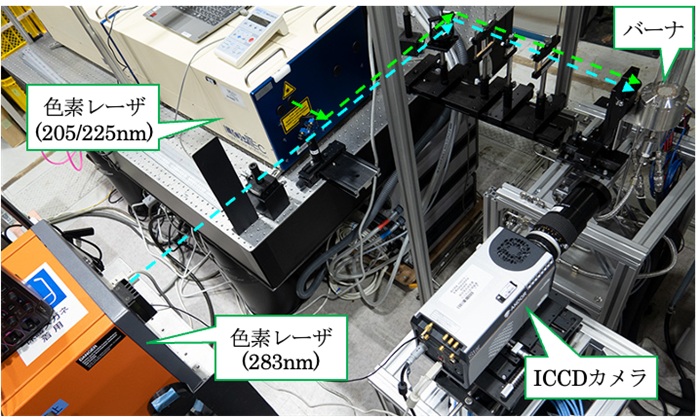

Ammonia-hydrogen combustion basic test facilities (FREA, Tsukuba)

Visualization of ammonia and hydrogen combustion conditions and exhaust gas measurement, visualization of ammonia spray, measurement of radical distribution using laser-induced fluorescence.

Team Member

| Title | Name |

|---|---|

| Leader, Team | ITO Hiroshi |

| Senior Researcher | SAKUMA Yuichi |

| Senior Researcher | FAN Yong |

| Researcher | SHEHAB Hazim |

| Attached to Research Team | INOUE Takahiro |