Compound Solar Cells Research Team

Research and development of low-cost III-V compound solar cells and high-performance CIS-based solar cells

Overview

The use of renewable energies is indispensable for achieving carbon neutrality, and expectations for photovoltaics are growing year by year.

In the 7th Strategic Energy Plan (February 2025), it is projected that the share of renewable energy in the power generation mix—22.9% in fiscal year 2023 (including 9.8% from solar energy)—will increase to around 40–50% by fiscal year 2040 (with solar energy accounting for approximately 23–29%).

However, the amount of photovoltaics installation per unit area in Japan is already the largest of any major country, and it is essential to maximize the expansion into new markets that have not been installed before.

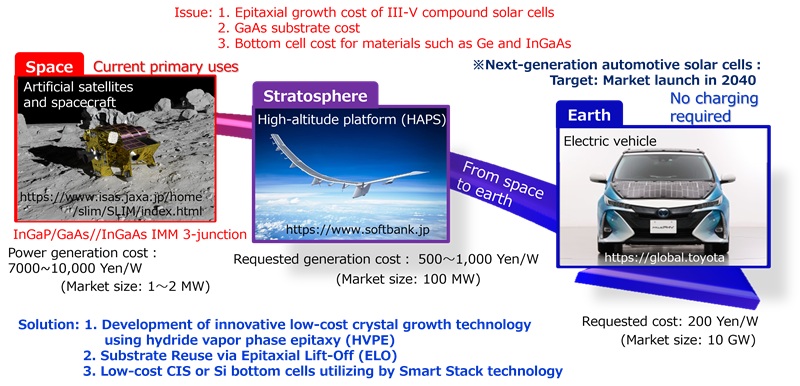

The Compound Solar Cells Research Team conducts research and development to produce high-performance III-V compound solar cells at low cost, which have been used only for space applications, and to apply them to mobile vehicles such as unmanned aerial vehicles and automobiles.

The solar cells made from chalcogenide compound thin film materials such as CIS (an abbreviation for a compound consisting of copper, indium, gallium, and selenium) have different characteristics from crystalline Si solar cells, which are currently widely used around the world, and are expected to create new markets.

For example, taking advantage of their lightweight and flexible characteristics, we are conducting research aimed at installation in places with load-bearing restrictions and on curved surfaces.

Research Target

In Japan, R&D of photovoltaic solar energy conversion is progressing, with a particular focus on perovskite solar cells, which have an installation target of 20 GW by 2040. At the same time, there are growing expectations for the development of tandem solar cells that combine perovskite with other solar cell materials.

The Compound Solar Cells Research Team is developing a low-cost mass-production hydride vapor phase epitaxy (HVPE) system that can achieve a module cost of 200 yen/W for tandem III-V compound solar cells to be widely used in electric vehicles by 2050.

The conversion efficiency is targeted at 35%. We are also advancing the development of tandem solar cells that integrate perovskite and chalcogenide-based CIS solar cells, which have a long-established research history.

The goal is to realize low-cost, high-performance solar cells that contribute to establishing renewable energy as a mainstay power source.

Research Outline

Cost reduction of III-V compound multijunction solar cells

Currently, the solar cell with the highest conversion efficiency is the tandem (multijunction) solar cell using III-V compound semiconductors.

By combining different types of solar cells, the entire wavelength of sunlight can be absorbed, resulting in high efficiency, but the high cost of crystal growth and substrates has prevented widespread use.

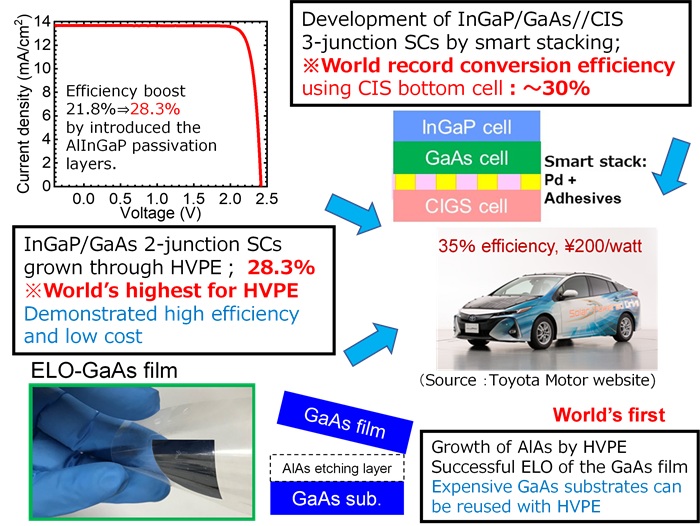

In order to lower the production cost, we are studying the fabrication of multijunction solar cells with a conversion efficiency of over 35% at low cost (200 yen/W) using the HVPE method, which can reduce the crystal growth cost by 90%, and the Smart Stack method, which can join low-cost Si or CIGS and III-V. Achieving this goal is expected to lead to applications in mobile vehicles, such as for unmanned aerial vehicles and automobiles.

Cost reduction of III-V compound semiconductor solar cells using hydride vapor phase epitaxy (HVPE) and smart stack technology

We will reduce the cost of III-V multijunction solar cells by reducing crystal growth costs using HVPE, utilizing low-cost bottom cells (CIS, Si) with smart stacks, and reusing GaAs substrates with epitaxial lift-off (ELO) technology.

Research and development of CIS-based solar cells

To this end, we are conducting R&D on enhancing the performance of CIS-based solar cells with various energy bandgaps, as well as on tandem integration technologies.

Research and development of high-durability, high-efficiency, and lightweight perovskite/CIS tandem solar cells

We are working on improving the performance of narrow-bandgap CIS-based solar cells for bottom cells and developing bonding technologies to realize high-performance tandem solar cells.

We are also engaged in R&D of wide-bandgap CIS-based solar cells for top cells that will enable the realization of high-performance tandem solar cells using all-inorganic materials.

Activities and Achievements

Conversion efficiency improvement of III-V compound solar cells by HVPE

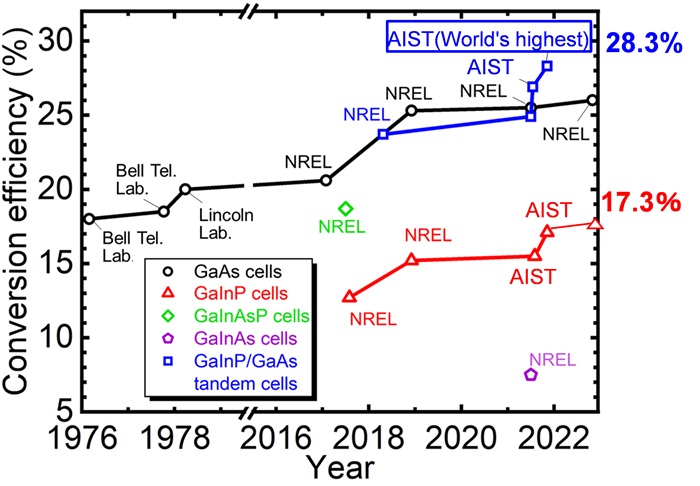

Fig.2 shows the highest conversion efficiencies of various solar cells fabricated by HVPE.

HVPE is an old technology that has been studied since the 1970s, but its development was stalled due to the inability to grow Al-based materials, which are essential for high-quality solar cells.

In recent years, our team and NREL have begun development, and we, who were the first to succeed in introducing high-quality Al-based materials into solar cells, hold the highest conversion efficiency records for InGaP/GaAs double-junction solar cells and InGaP single-junction solar cells, respectively.

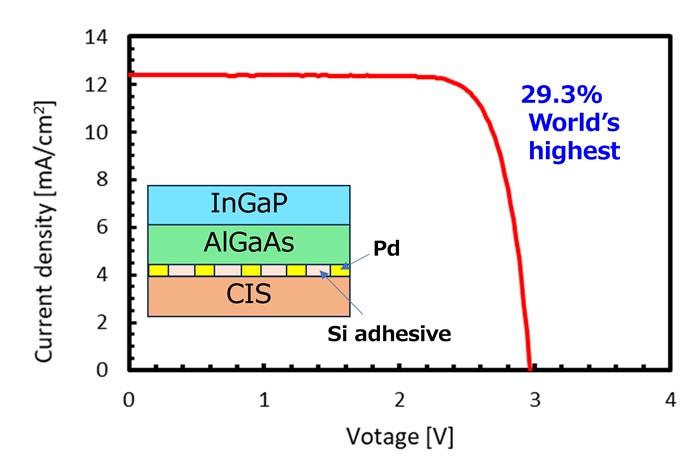

Improved efficiency of smart stacked InGaP/GaAs/CIS solar cells

Smart Stack technology is an excellent technology developed by AIST that enables the fabrication of 2-terminal multijunction solar cells in a low-cost and simple method.

In the development of this technology, the world's highest conversion efficiency of 29.3% was achieved for InGaP/GaAs//CIS triple-junction solar cells (//: Smart Stack) by developing a new type of Smart Stack with silicone adhesive. This is the world's highest conversion efficiency for a 2-terminal multijunction solar cell with CIS as the bottom cell, and is registered as a world record in a journal.

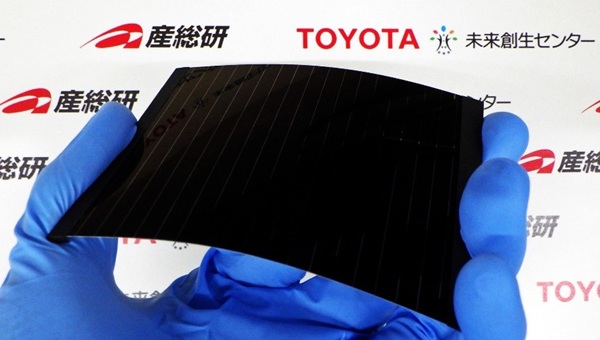

Record efficiency for lightweight, flexible monolithically integrated CIS-based solar minimodules

A CIS-based solar minimodule with a multi-cell interconnected structure on a single lightweight flexible substrate has achieved a record photovoltaic efficiency of 18.6% over an area of approximately 68 cm2).

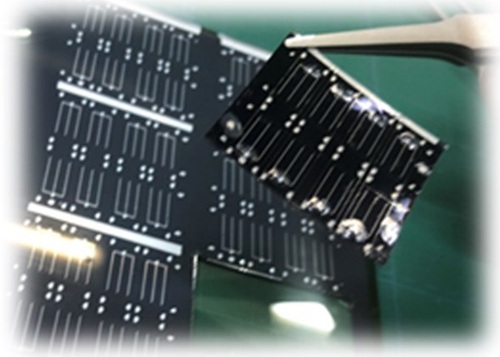

Record efficiency for lightweight and flexible CIS-based solar cells for tandem bottom cells

A narrow-bandgap (approximately 1.0 eV) CIS-based solar cell fabricated by low-temperature CIS growth process on a polyimide film substrate has achieved a record photovoltaic efficiency of 21.2% over an area of approximately 0.5 cm2).

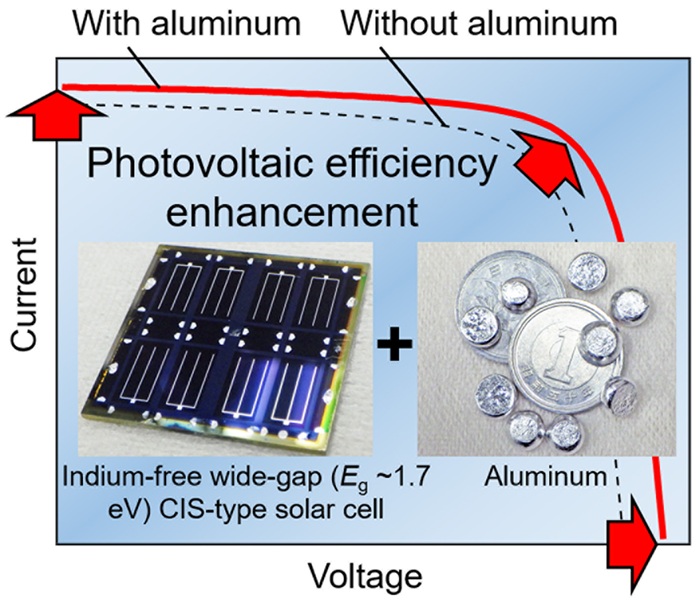

Record efficiency for elemental indium-free wide-bandgap CIS-based solar cells

A wide-bandgap (approximately 1.7 eV) CIS-based solar cell, expected to be used as a top cell in tandem solar cells, has achieved a world-record photovoltaic efficiency of 12.25% over an area of approximately 0.5 cm2).

Main Research Facilities

HVPE system (6-inch) for mass production demonstration

A low-cost crystal growth system for III-V compound semiconductors.

The cost of crystal growth can be reduced by 90% compared to conventional technology.

R&D is conducting jointly with Taiyo Nippon Sanso Co., Ltd. with a view to demonstrating mass production using a large-area 6-inch GaAs substrate.

CIS-based thin-film growth equipment, solar cell and minimodule fabrication process equipment, solar cell characterization equipment (solar simulator, spectral response measurement system, photoluminescence measurement system, etc.)

We have a complete set of equipment for fabricating CIS-based solar cells, as well as various instruments for evaluating the performance of the fabricated solar cell devices.

Team Member

| Title | Name |

|---|---|

| Leader, Team | KAMIKAWA Yukiko |

| Chief Senior Researcher | SUGAYA Takeyoshi |

| Senior Researcher | OSHIMA Ryuji |

| Senior Researcher | NISHINAGA Jiro |

| Senior Researcher | KAMIKAWA Yukiko |

| Researcher | NISHIDA Takeshi |

| Principal Researcher (Attached to Research Team) |

ISHIZUKA Shogo |